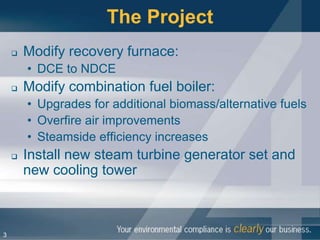

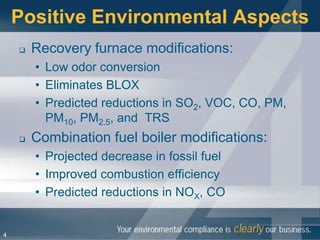

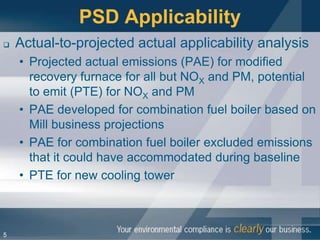

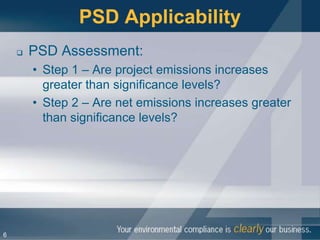

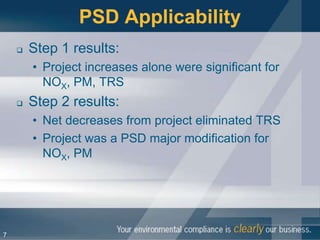

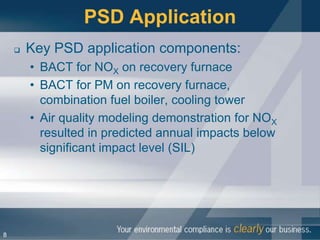

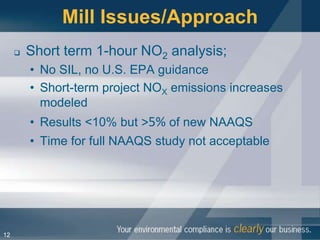

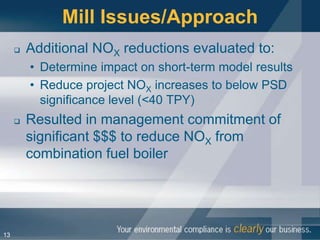

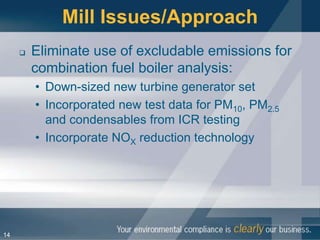

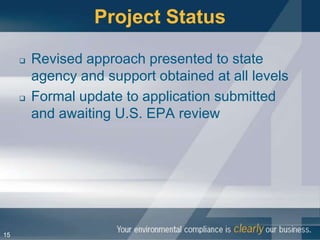

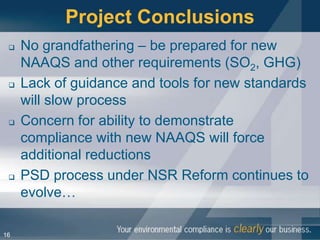

This document summarizes a case study of a mill project that required a PSD permit. The mill modified its recovery furnace and combination fuel boiler and installed a new steam turbine generator and cooling tower. The project required a PSD applicability analysis which found increases in NOx, PM, and TRS above significance levels. The mill developed a PSD application including BACT and air quality modeling. The permit application process took over a year and required additional NOx reductions to address EPA concerns and new standards. The conclusions were that new standards will slow PSD permitting and force additional emissions reductions.