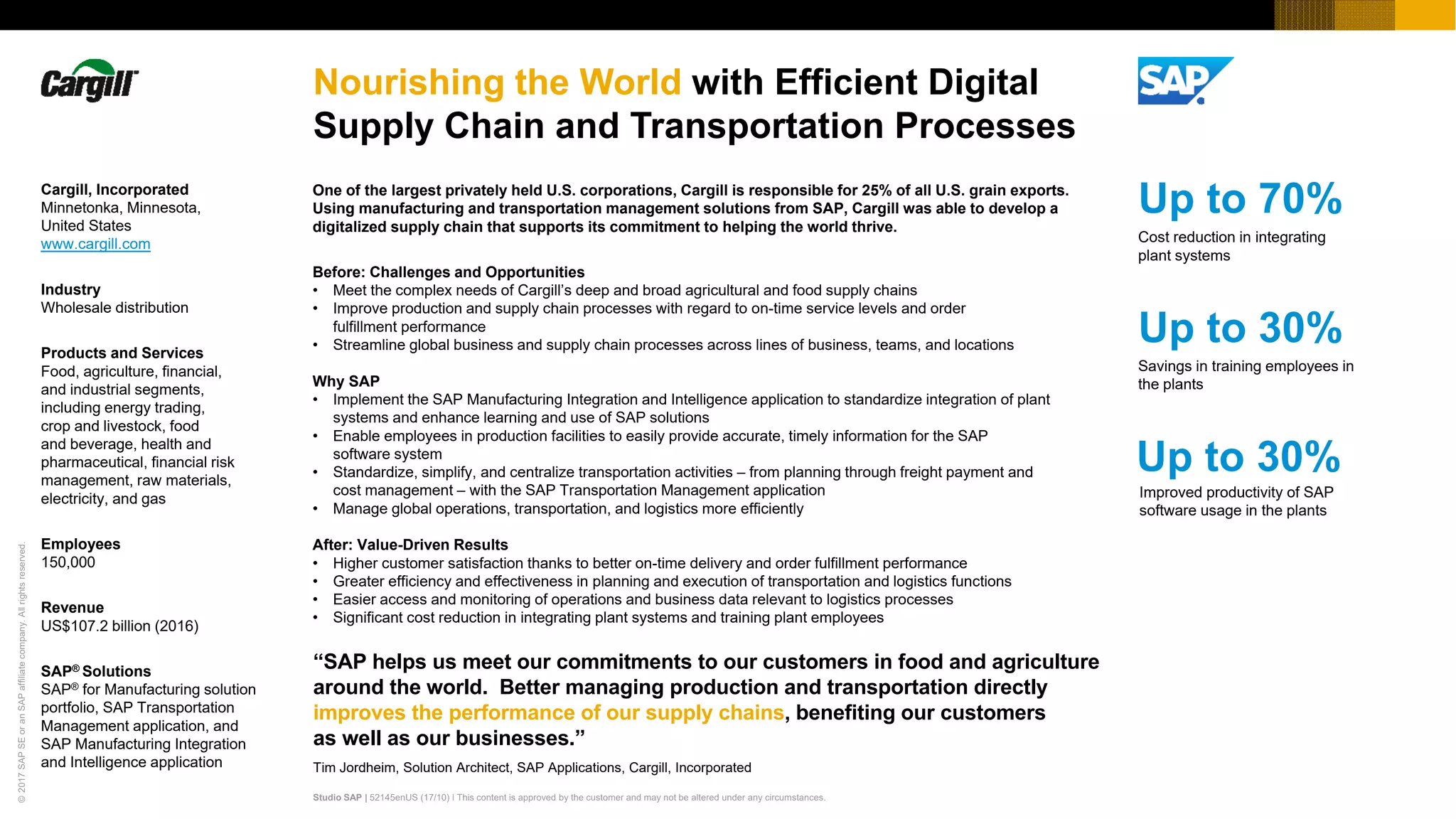

Cargill, a global food provider, developed a digital supply chain using SAP solutions to more efficiently transport food from farms to customers. This improved on-time delivery, increased order fulfillment rates, and saved up to 30% on training and 70% on integrating plant systems. The digital supply chain helps Cargill's mission of nourishing the world.