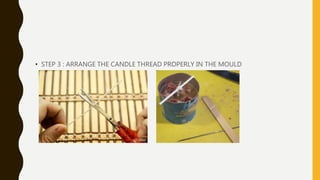

The document summarizes the production process of candles. It outlines the raw materials needed which include candle wax, stearic acid, and candle thread. It then lists the required machinery such as candle molds, mixers, burners, and packaging materials. Finally, it provides the key steps in the process which are chopping and melting the wax, adding stearic acid, arranging the wick in the mold, pouring the melted wax, and removing the solidified candles to package them.