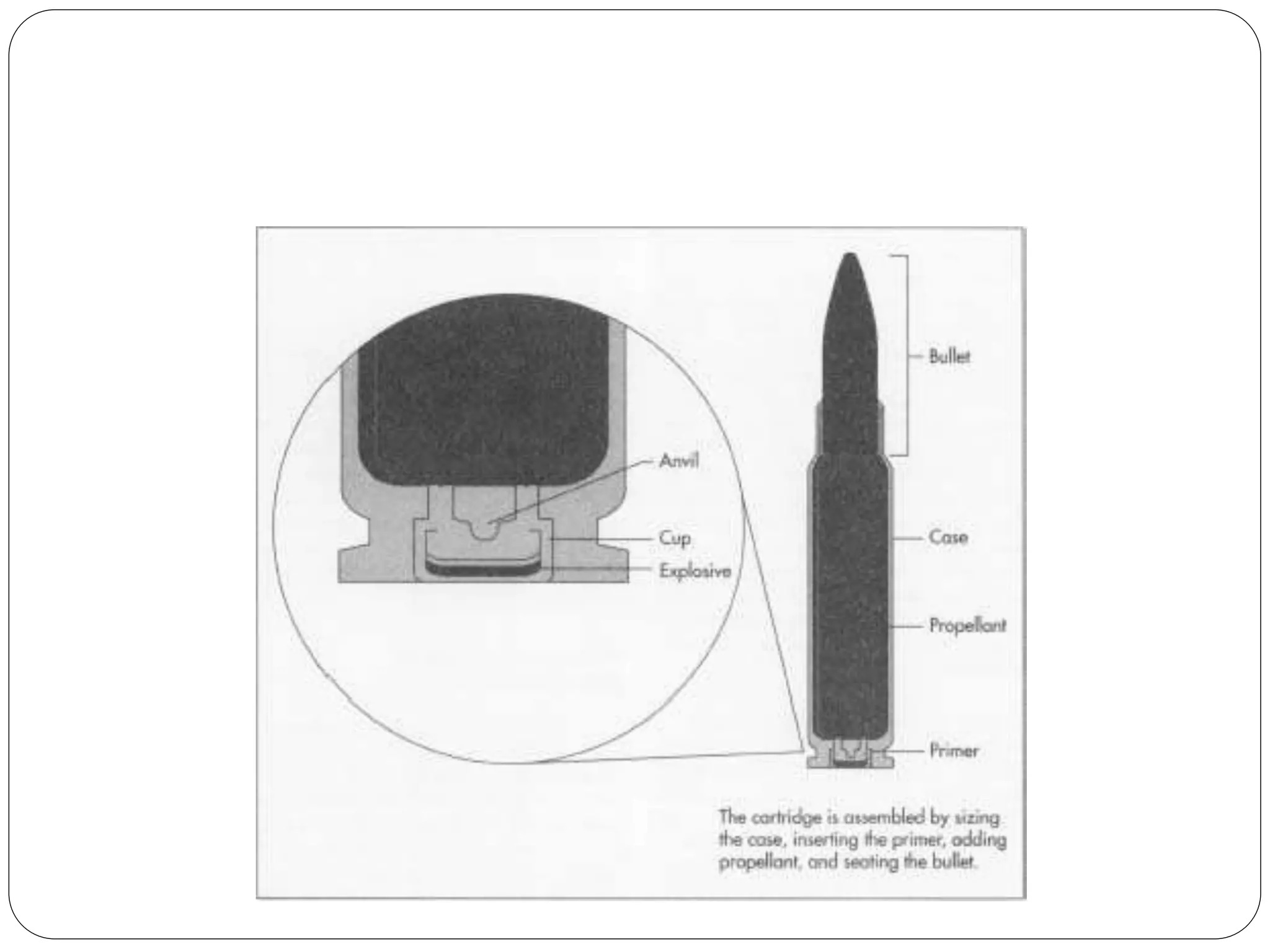

The document summarizes the process of manufacturing bullet cases. It involves several steps: brass strips are formed, cups are cut from the strips and drawn into longer cases through multiple drawing operations followed by annealing. The cases then undergo operations like trimming, indenting, heading, stamping, piercing, tapering, annealing and quality checks to prepare them for ammunition loading. The process requires strict quality control at various stages to ensure dimensional accuracy of the final bullet cases.