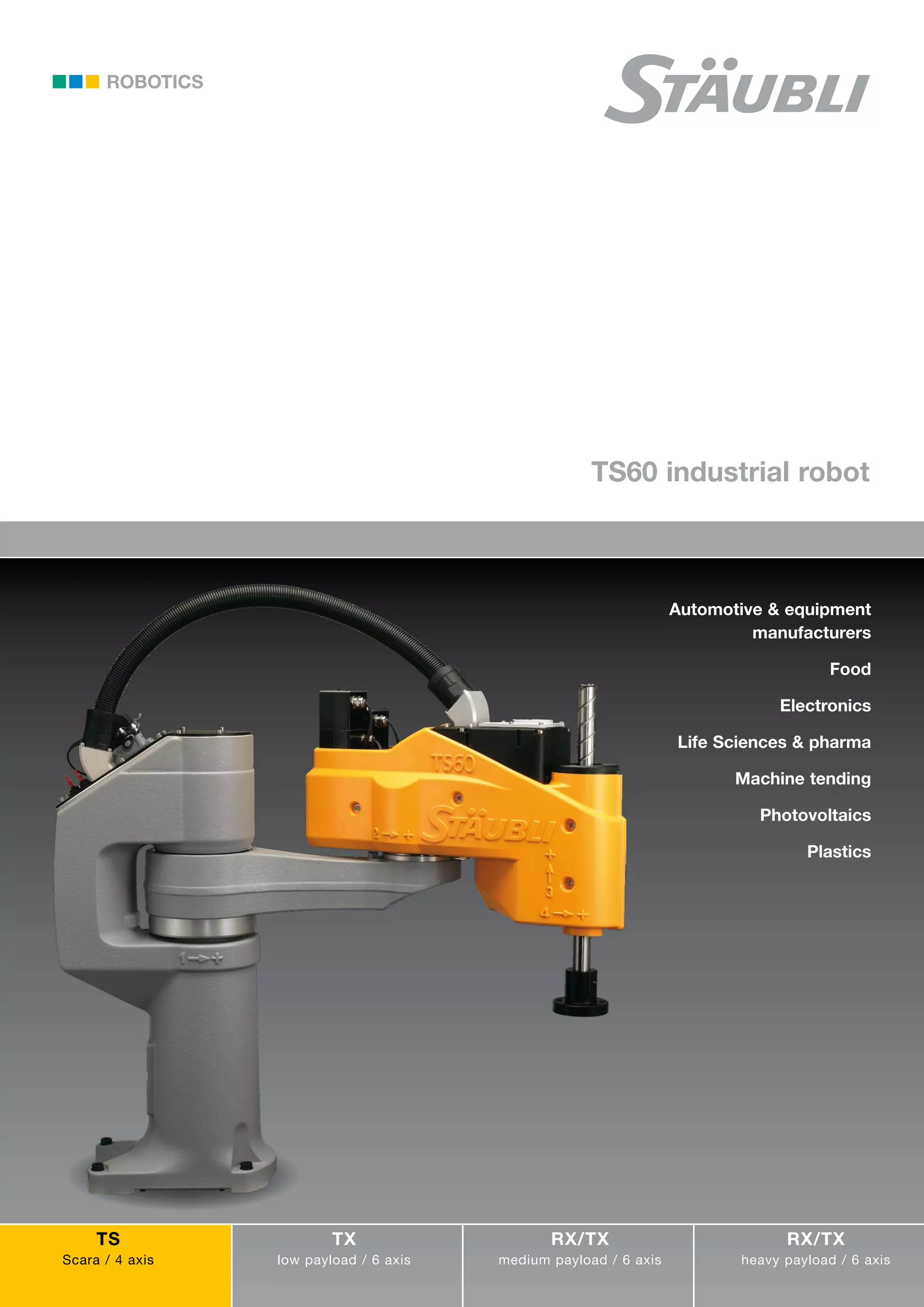

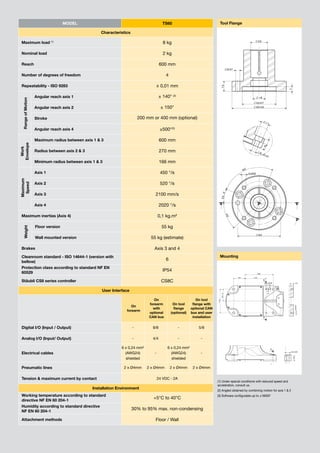

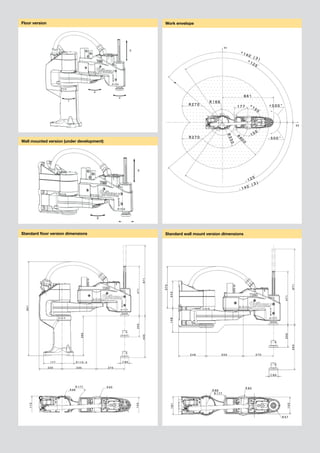

The TS60 industrial robot from Staubli can be used in automotive, equipment manufacturing, food processing, electronics, life sciences, and other industries. It has a 4-axis SCARA design with a 600mm reach and can handle payloads up to 8kg. The TS60 offers high speeds up to 520 degrees per second and repeatability of 0.01mm. It has an IP54 rating and can be floor or wall mounted.