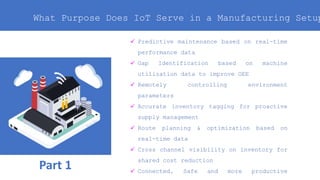

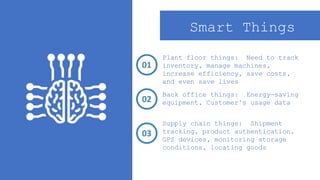

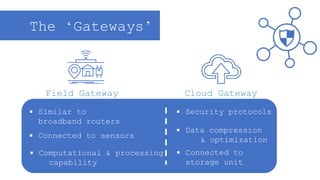

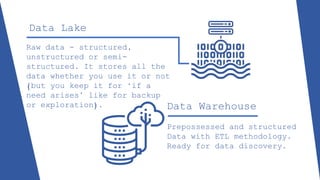

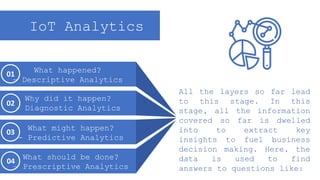

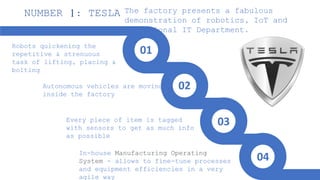

The document discusses the significant impact of IoT technology in industrial settings, highlighting its applications in predictive maintenance, inventory management, and operational efficiency. It emphasizes the importance of data collection and analysis through various IoT components like gateways and storage units, ultimately leading to actionable insights. The document also shares case studies from companies like Tesla, Caterpillar, and Daimler, illustrating the transformative benefits of IoT in manufacturing.