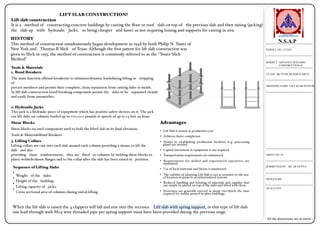

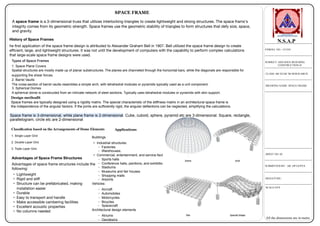

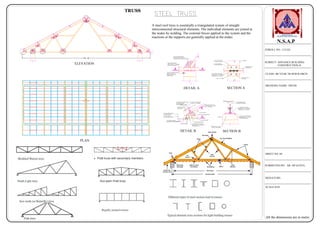

This document provides detailed specifications and information about the design and construction of telecommunications towers, including types such as guyed, self-supporting, and monopole structures. It also discusses the lift-slab construction technique in building construction, along with the advantages and methods for using space frames. Overall, it serves as a technical guide for students in their 4th year of architecture studies.