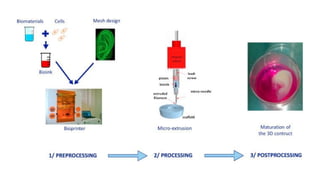

3D visualization involves creating digital representations of objects using various imaging techniques.

In bioprinting, this often involves medical imaging techniques like CT scans and MRI to capture the anatomical structure of the tissue or organ to be printed.

These images are then used to create a digital 3D model for designing the bioprinted structure.