Better Builder Magazine brings together premium product manufactures and leading builders to create better differentiated homes and buildings that use less energy, save water and reduce our impact on the environment. The magazine is published four times a year.

![BETTERBUILDER.CA | ISSUE 52 | WINTER 2024

18

wide popularity sends “a great signal

to the industry that customers are

keenly interested in solutions. And

that paves the way for a clean energy

future. Ontarians want an energy

system that lowers emissions over

time, but they also want a system

that’s safe, reliant, resilient, cost

effective and energy saving, like what

we see in hybrid homes.”

Keynote speaker Chris Magwood

of Builders for Climate Action (see

photo on page 17) spoke about the

SHF’s mandate to engage, educate

and communicate with builders about

energy rating and carbon counting.

To that end, he emphasized the

importance of understanding the

difference between embodied and

operational carbon in construction.

“Everyone in this room has done

their part in reducing emissions,”

Magwood said. “We’re generating a

fraction of the carbon emissions we

once did.”

But there’s still a way to go, he

added. While builders are producing

less emissions, some of the materials

used are being manufactured with high

carbon consumption. To drive the point

home, he said that “materials going into

our homes have the carbon footprint

of the entire economies of Estonia or

Costa Rica. Consider this: a year of

homebuilding in the GTA produces

840,000 tonnes [of carbon], equivalent

to 183,000 cars. That’s most of the cars

on the road.”

All levels of government have

weighed in on this, and the Canada

Green Building Strategies (a 2024

federal mandate) made it clear that

embodied carbon must be calculated.

While that may sound like just one

more thing to worry about when

building a home, Magwood assures

that the tools are simple. “Basic math.

The amount of material going into

building, multiplied by the emissions

factor, equals the embodied carbon of

the building.”

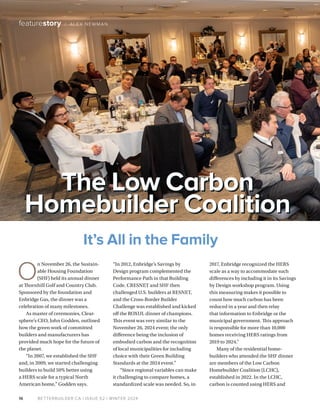

Alireza Hajiyousef of York Region.

Left to right: Susan Lahey of the Town of East Gwillimbury,

Vania Ottoborgo of Averton Homes, and Michael Lio of buildABILITY.

Paul De Berardis of RESCON and

Ferdi Toniolo of the City of Richmond Hill.

Alexandra Service of the Town of Caledon

and Dave Henderson of RESCON.

For their collaborations with builders, the munici

palities of Caledon, East Gwillimbury, Richmond

Hill and York Region were given certificates.](https://image.slidesharecdn.com/betterbuilder52win24-250313133624-691ad3e2/85/Better-Builder-Magazine-Issue-52-Winter-2024-20-320.jpg)