Better Builder Magazine brings together premium product manufactures and leading builders to create better differentiated homes and buildings that use less energy, save water and reduce our impact on the environment. The magazine is published four times a year.

![BETTERBUILDER.CA | ISSUE 54 | SUMMER 2025

73 — well below a resale home (130).

An average Beazer home by 2021?

Try 56, a number which has been

dramatically improved upon since.

The builder is also a big believer in

third-party verification. Cordes says

anyone can simply make the claim that

they’re building better. But having that

backed up by a 32-point checklist adds

a major element of assurance.

“We really do want to make sure

that we’ve got the best verification that

we can, and making sure that it’s all as

legitimate as it can be.”

Tantamount to the goals of any good

builder that’s focused on sustainability

is how to be part of the climate change

solution, and Beazer is no different.

“I think the most important thing

that we can do is continue to evolve,”

says Cordes. This was part of her

messaging in a recent training session

for one of the company’s top divisions.

While Cordes told them how wonderful

it was that they’ve been efficient while

being both budget conscious and

sophisticated in their approach, she

also stressed the importance of not

sitting on their laurels.

“We’re not stopping [here],” she

says. “There’s no one specific thing

that we can do to fix climate change, so

what we can do is continue to build a

better home, just continue to evolve our

building practices.”

Now that Beazer has pretty much

nailed the whole Zero Energy Ready

thing, it’s been adding renewables and

storage.

In terms of their next innovation,

she says that solar with storage is a

substantial initiative for the company,

one that she currently spends a good

chunk of her time working on.

“I think that’s the very near future

for us,” Cordes says. “Ultimately, I

think that we are pretty nimble in

terms of how we approach the different

technologies that we use because we’re

constantly trying to do better and

pulling data from the divisions that

are doing all of these new things and

understanding what could be next.” BB

Rob Blackstien is a

Toronto-based freelance

writer. Pen-Ultimate.ca

19

Innovative and user-friendly form for

sustainable and resilient design.

Embedded

cross-ties

Two diagonal cross

ties which virtually

eliminate the chance

of blow out.

FormLock™

interlock

Patented interlock

with moisure drain

system

No tying required

Built-in rebar holders

eliminate tying

Multiple block

types available

Including straight, 90°

corner, 45° corner, taper

top, brickledge, t-block,

and radius blocks

AmvicTM

Insulated

Concrete Forms

6” & 8” CORE

also available in R22

with core sizes of

4”, 6”, 8”, 10” & 12”

R30

alleguard.com

1 (877) 470 9991

Insulated Concrete Forms

TM

C

M

Y

CM

MY

CY

CMY

K

Better Builder Island Ad 4.875x7.375 Spring 2024.pdf 1 2/21/2024 10:33:23 AM](https://image.slidesharecdn.com/betterbuilder54sum25-250917141706-436319e5/85/Better-Builder-Magazine-Issue-54-Summer-2025-21-320.jpg)

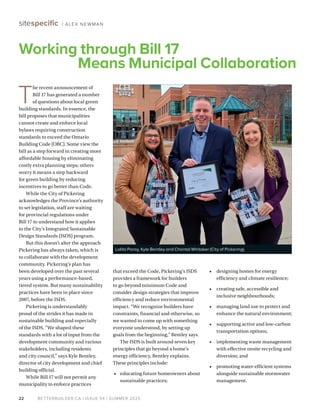

![BETTERBUILDER.CA | ISSUE 54 | SUMMER 2025

Going to Town

in Caledon

T

he Town of Caledon has con

sistently ranked high among

Canadian municipalities for its

green building and energy-efficient

practices and standards. In 2023,

Caledon was named the Greenest Town

in Ontario.

An early adopter of Caledon’s

mission, Townwood Homes completed

the EnerGuide rated development at

Riverstone Golf and Country Club in

Brampton in 2006.

Two decades later, working with

Rosehaven Homes, Townwood has

released the Mayfield Collection in

Caledon. The community has achieved

a combined water reduction of two

million litres and a carbon emission

reduction of 64 tons of CO2. This

accomplishment secured Townwood

its recent win at the Cross Border

Builder Challenge for its low Home

Energy Rating System (HERS) score of

42 (with an average 1.59 air changes per

hour [ACH] on the first eight homes).

This score outperforms a Zero Energy

Ready designation.

A zero energy-ready home is one

that can be transitioned towards net

zero, producing as much energy as

it consumes, explains Townwood’s

project manager, Marc Bozzo.

Although Bozzo is unsure that

net zero is a realistic goal in southern

Ontario for a variety of reasons, Zero

Energy Ready is. And it’s a valuable

selling point, he says, because

“homeowners are definitely interested

in future-proofing a home that can be

easily retrofitted.”

For example, in Townwood’s King

City and Aurora townhome projects,

homes are future-fitted with conduits

for solar panels running from basement

to rooftop, as well as designated spaces

for battery storage units.

Reducing energy consumption and

emissions can be costly, so why make

the effort? Bozzo can list a few reasons

why: “There are long-term utility savings

and there’s increased comfort. And a

higher-efficiency home with hot water

tanks and an energy recovery ventilator

(ERV) is going to save money long term.

Plus, offering a home that’s better than

Code is a way to distinguish ourselves as

quality builders in a saturated market.”

With real estate costs what they are

these days, more people are staying put

longer and moving less. This makes

future-proofing even more important,

“hence the net zero energy-ready features

in the Mayfield Collection,” Bozzo says.

Developed and constructed

in collaboration with Rosehaven,

Mayfield’s substantial sustainability

checklist is impressive: low-flow

faucets, showerheads and 3.5-litre

toilets to conserve water; low solar

heat gain glass in windows that are

filled with low-e argon (which allows

heat into the house in winter and

keeps heat out in summer); ERVs; and

drain water heat recovery systems.

Homes are tested to be airtight beyond

Code, while bumped-up insulation

keeps temperatures steady. Each new

home also factors in comfort with a

zoned HVAC system with separate,

programmable wifi thermostats on the

ground level and second floor for more

consistent comfort.

As well, homes have 100% LED

lighting, structural insulated wall

sheathing and cellulose attic insulation

to reduce carbon footprint. All together,

this contributes to the 20% better-than-

Code package in terms of performance.

Awards are wonderful for a company’s

reputation and are added right away into

marketing materials. But the recognition

has another benefit, Bozzo says.

“I see the biggest win as the recog

nition for our trades. It’s a reward for

a job well done for the people on-site

who do the work. Our trades do it all —

airtightness, sealing, insulation, framing

— all going toward making a home that’s

airtight. They take huge pride in their

work and that’s recognition that their

work is highly regarded.” BB

Alex Newman is a writer, editor and

researcher at alexnewmanwriter.com.

29

buildernews / ALEX NEWMAN

42

2017 SB-12 REFERENCE HERS 57

HERSSCORE

Paul Guglietti (Townwood Homes),

Trudy Puls (ROCKWOOL) and Marc

Bozzo (Townwood Homes).

“Homeowners are

definitely interested

in future-proofing a

home that can be

easily retrofitted.”](https://image.slidesharecdn.com/betterbuilder54sum25-250917141706-436319e5/85/Better-Builder-Magazine-Issue-54-Summer-2025-31-320.jpg)