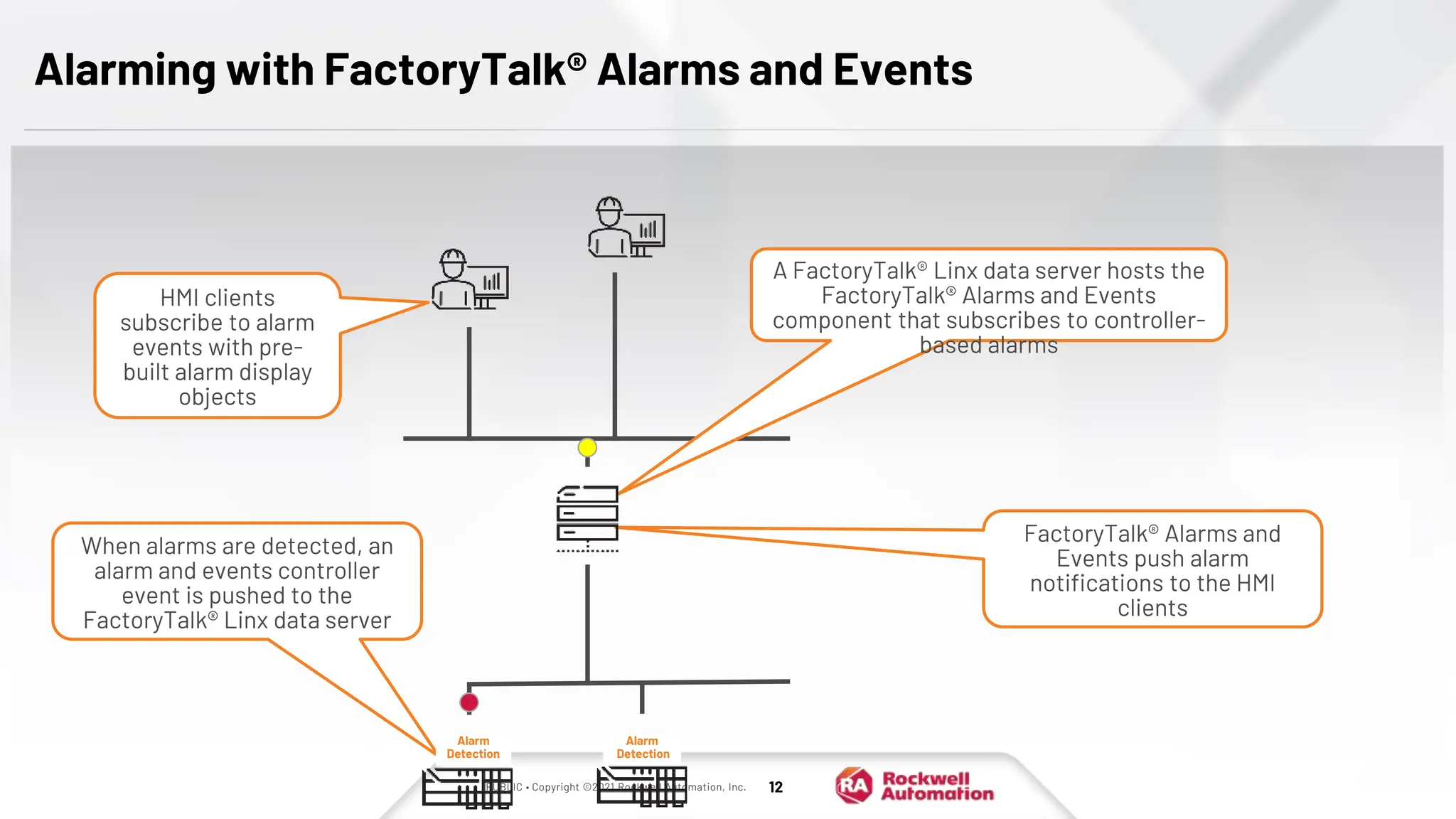

The document discusses integrating FactoryTalk View SE with Logix controllers for alarming and diagnostics. Key benefits include:

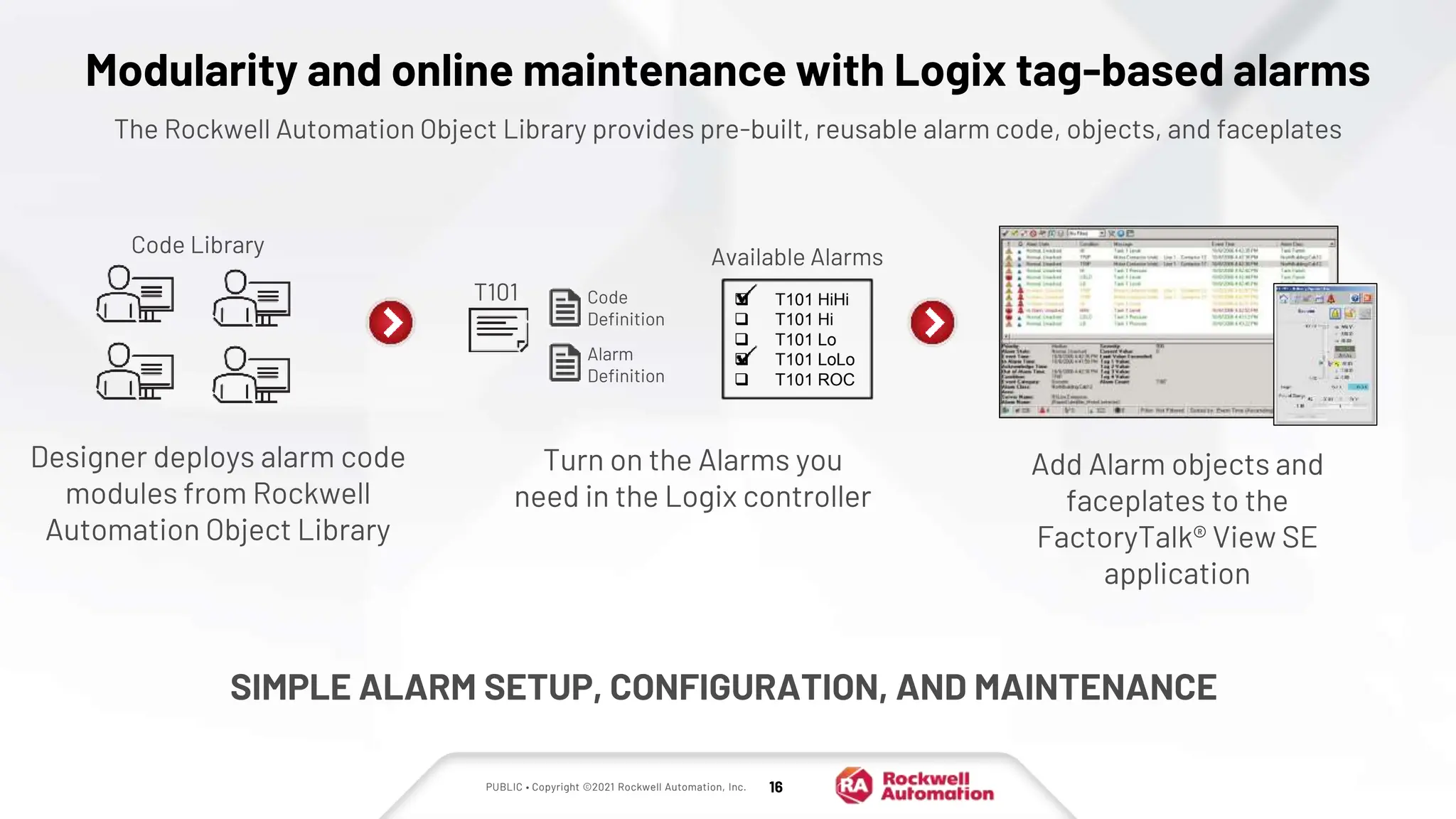

- Alarms and device diagnostics are automatically shared between Logix controllers and FactoryTalk View SE without additional configuration

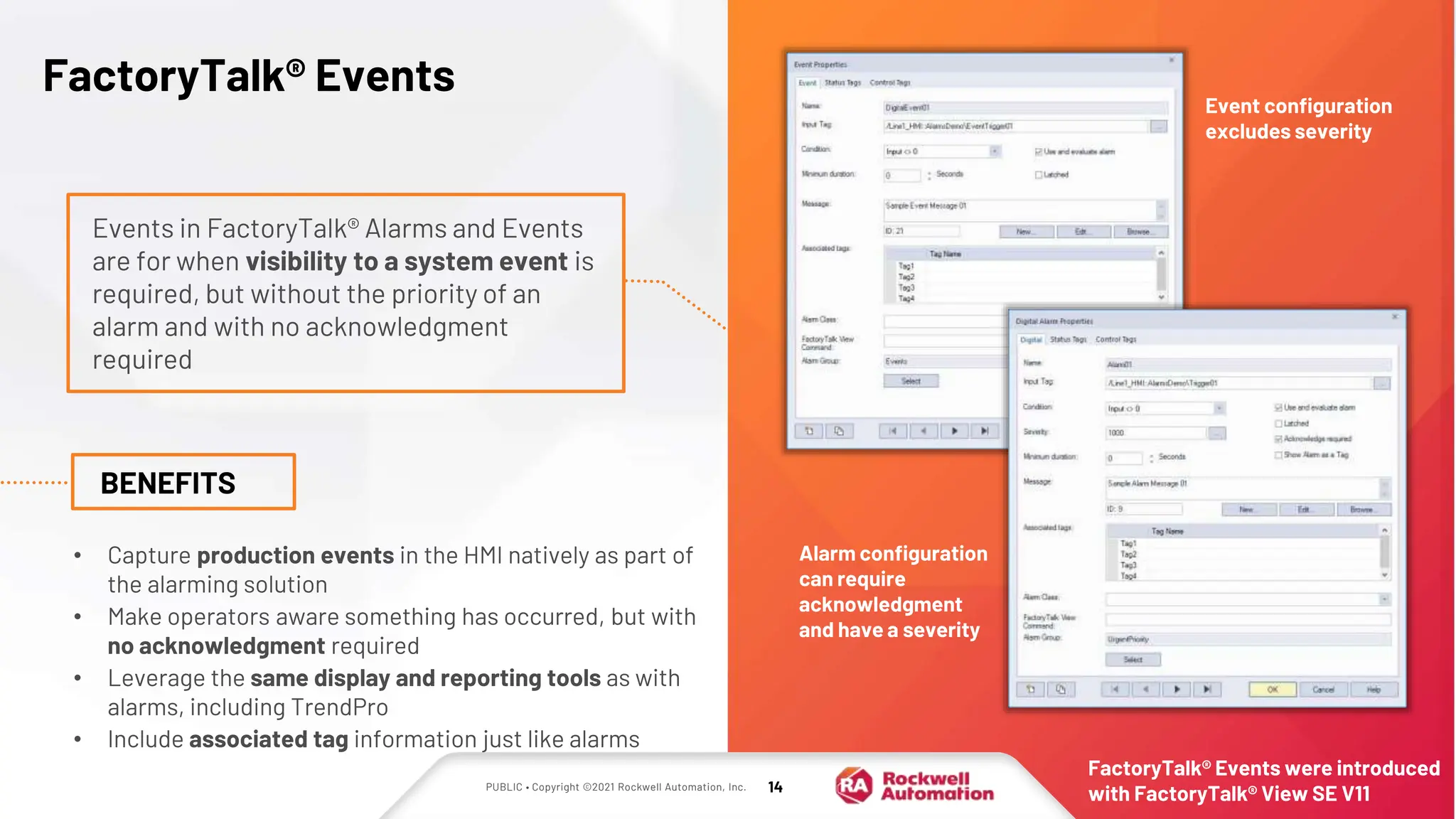

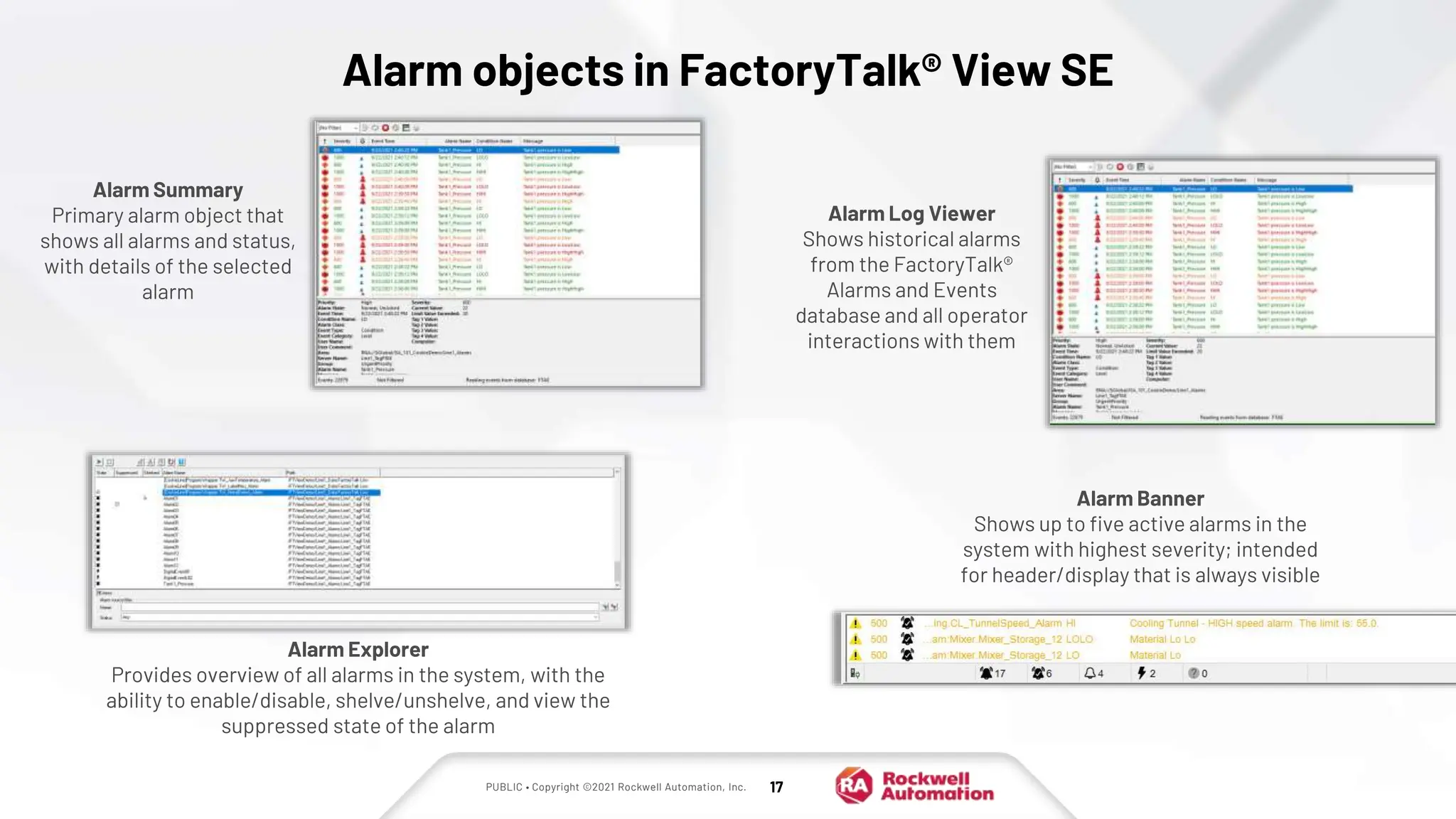

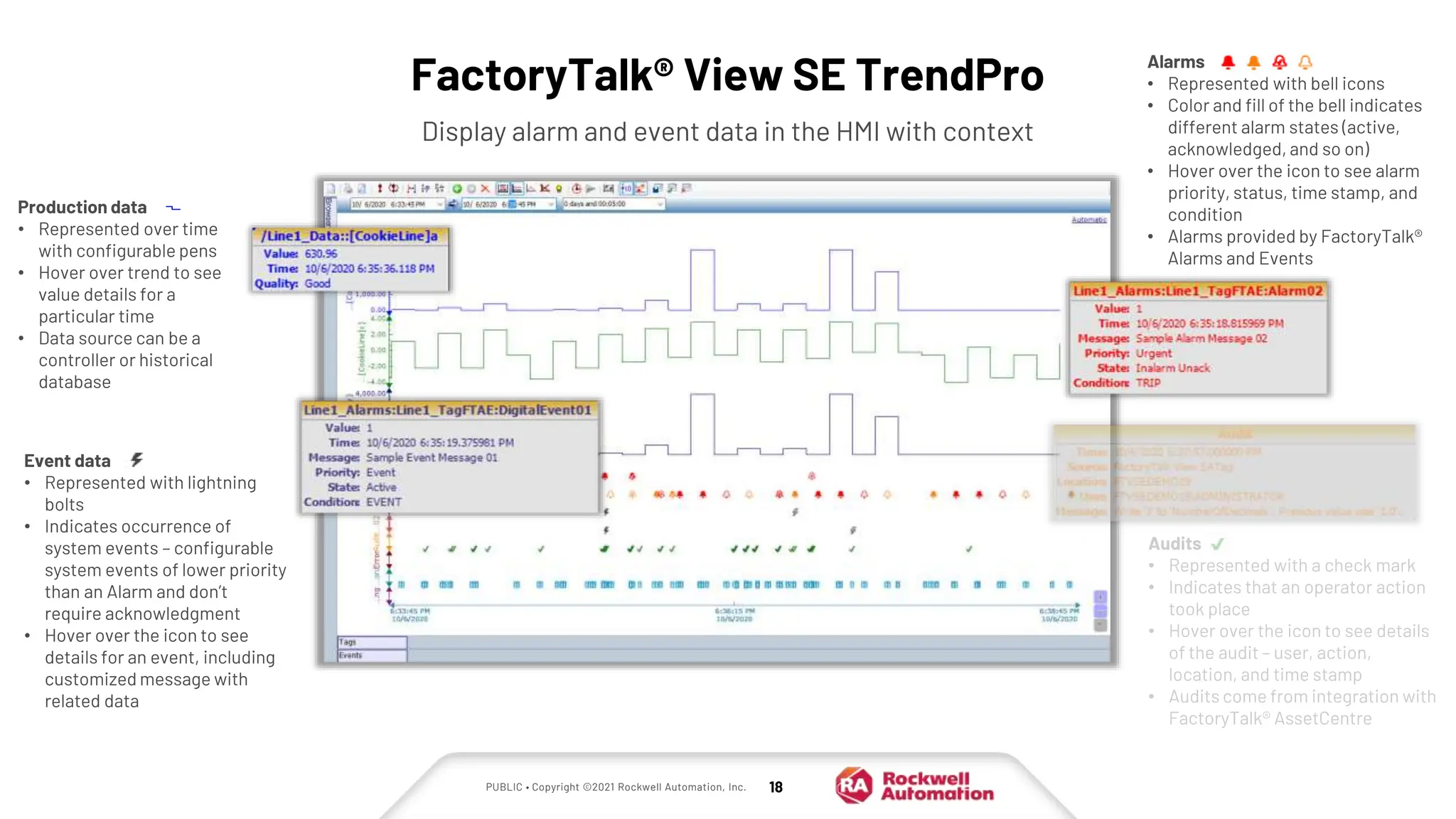

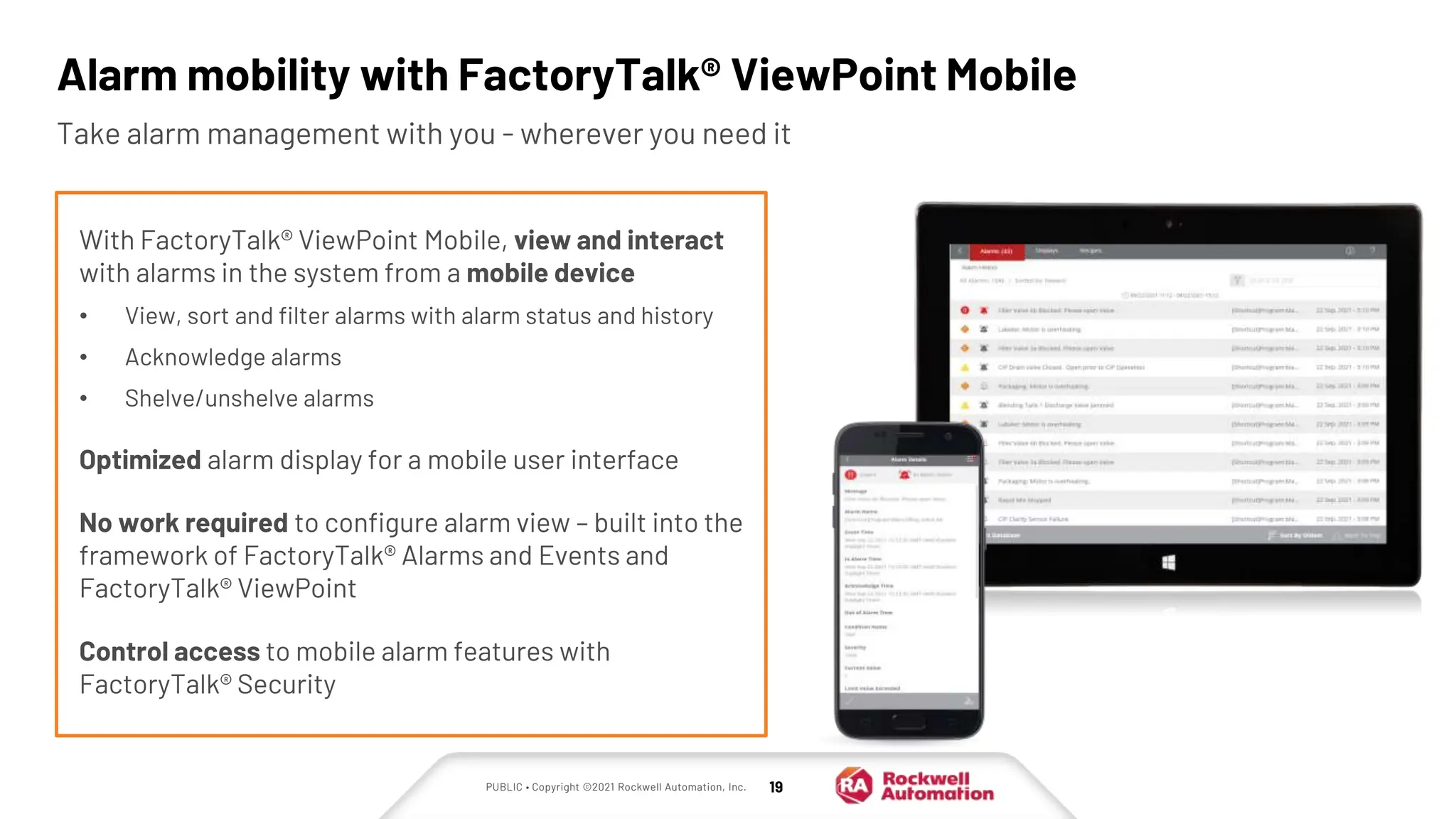

- Flexible alarm interaction options allow acknowledging, shelving, and viewing alarms from HMIs, web browsers, and mobile devices

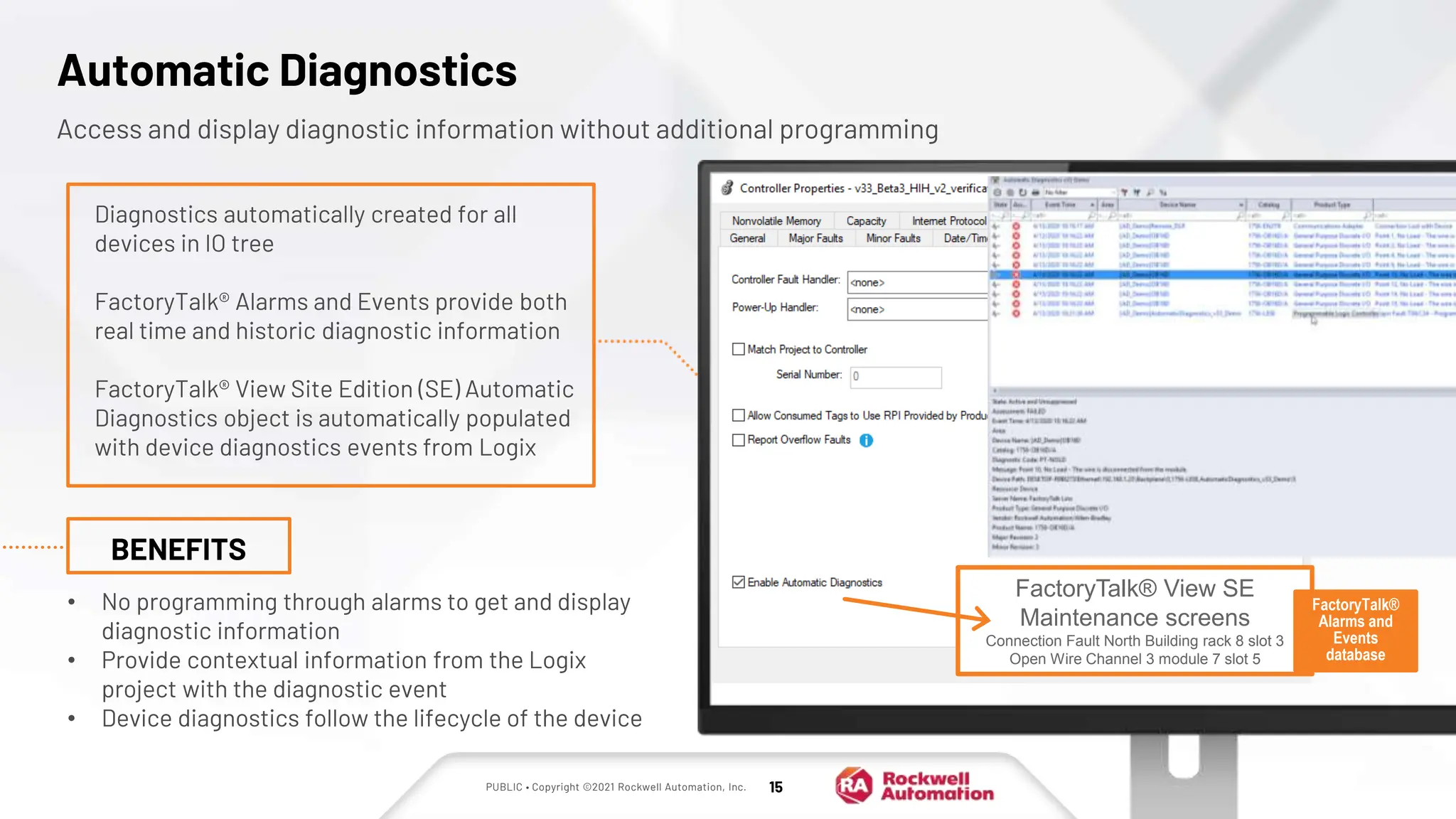

- Automatic diagnostics provide diagnostic information from Logix controllers in FactoryTalk View SE without additional programming