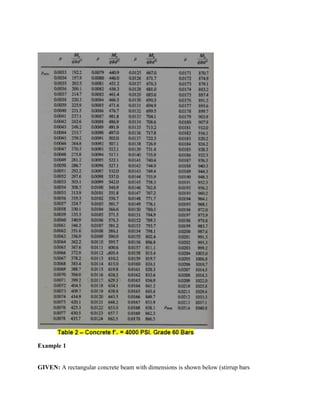

This document provides an example of using a design aid table to help size reinforced concrete beams more efficiently than through trial and error. It gives two examples - one solving for the usable moment capacity of a given beam using the table, and another designing a beam to meet given criteria. The table allows looking up the usable moment capacity directly from values of moment, concrete strength, steel grades, and beam dimensions. This streamlines the iterative process of beam design.