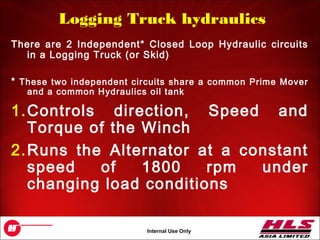

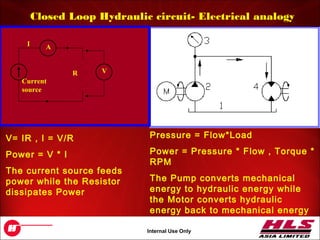

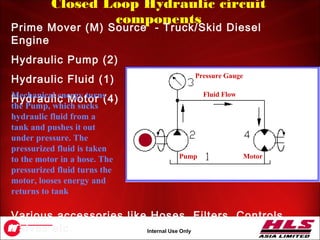

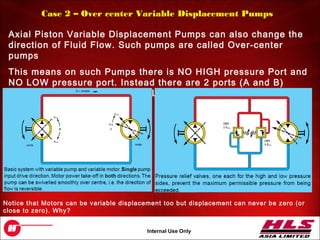

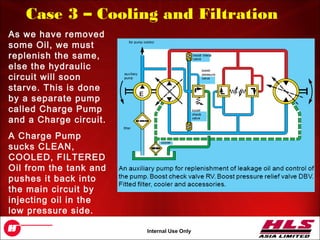

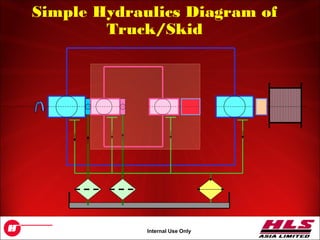

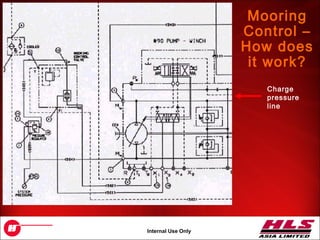

This document provides training information on basic hydraulics systems used in logging trucks. It discusses key components of closed-loop hydraulic circuits including pumps, motors, valves, tanks, hoses and filters. It explains how hydraulic systems are used to power the winch and alternator and describes important hydraulic principles like Pascal's law, pressure, flow and displacement. The document summarizes the two independent hydraulic circuits in logging trucks - one for the winch and one for the alternator - and provides diagrams of basic and advanced truck hydraulic systems.