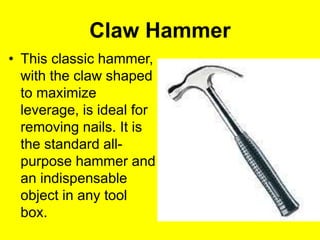

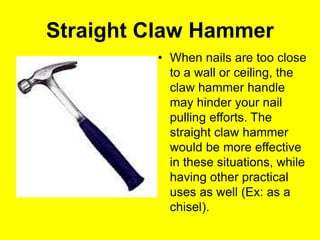

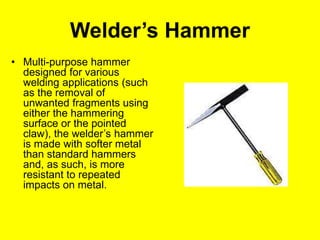

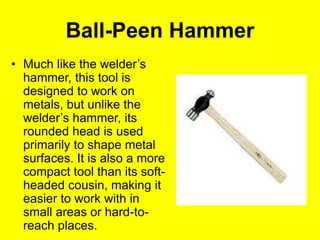

This document discusses different types of hammers used in carpentry. It describes claw hammers, straight claw hammers, drywall hammers, bricklayer's hammers, welder's hammers and other specialty hammers. It also discusses hammer handles, heads, weights and general maintenance tips. The ideal all-purpose hammer is a 16oz claw hammer with a handle that feels comfortable and balanced to the user. Proper use and storage can maximize a hammer's lifespan.