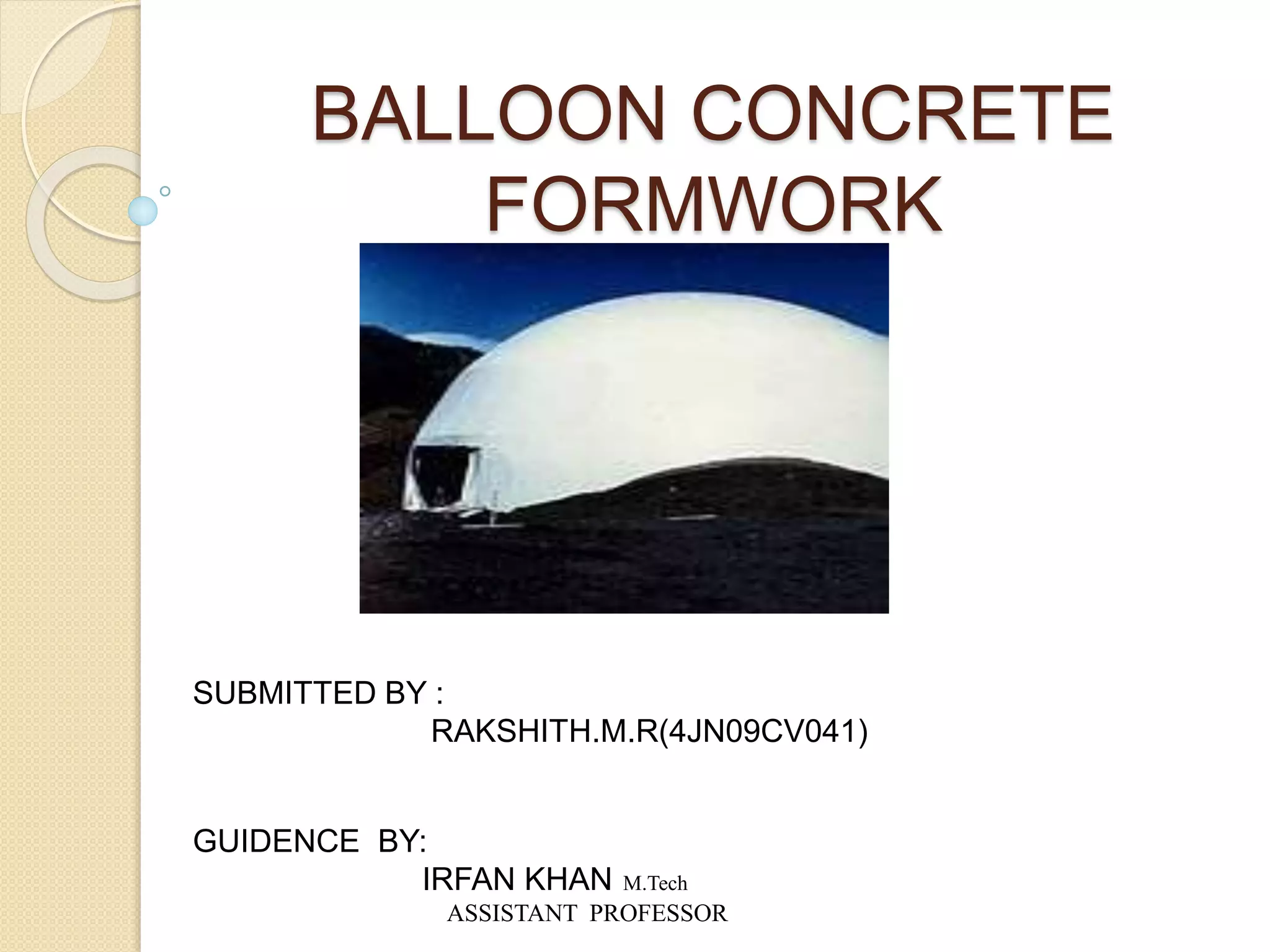

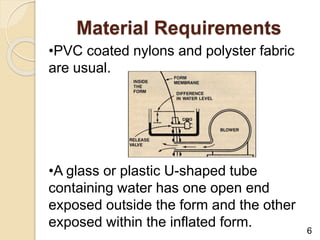

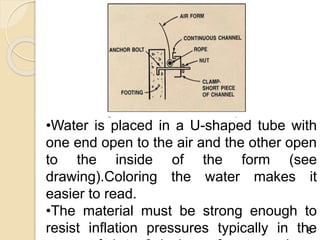

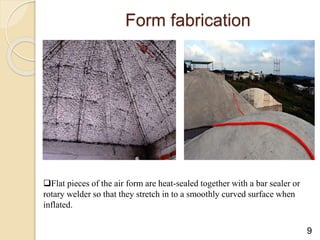

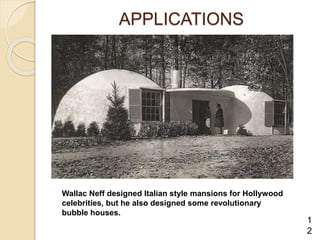

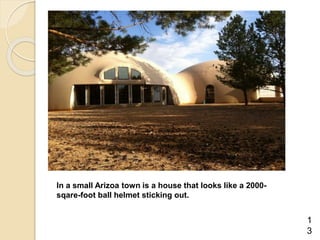

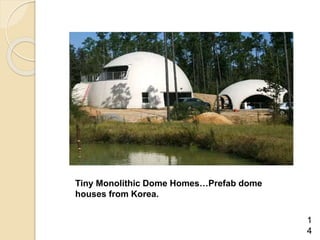

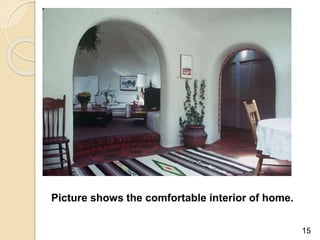

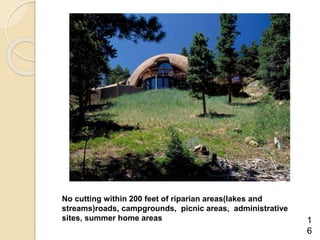

This document discusses balloon concrete formwork, which uses an inflated balloon as a single form for concrete structures. The balloon is inflated with bumps that form windows and doors, and welded wire mesh is cut to size and sprayed with concrete to strengthen the structure. Foamcrete, which has a higher proportion of air bubbles, is used as the concrete mix. The document outlines the design, materials, fabrication, installation, applications, and advantages of balloon concrete formwork, concluding that it provides a low-cost and efficient construction method for large concrete domes.