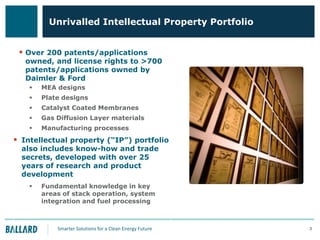

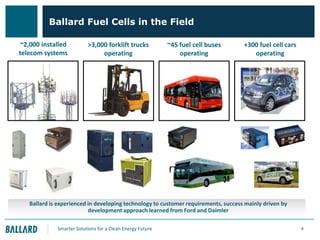

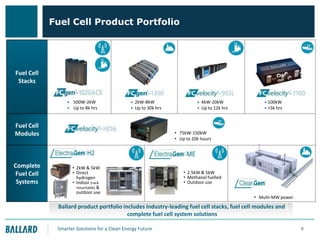

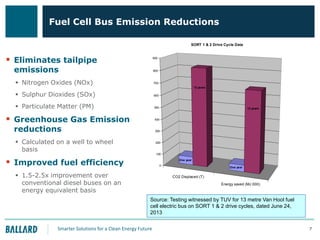

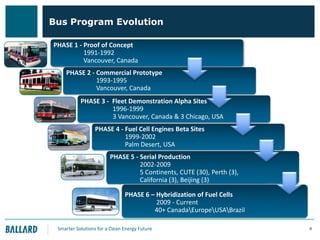

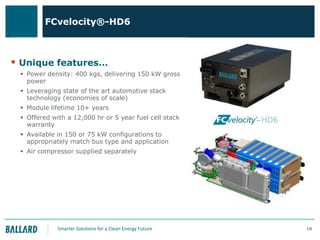

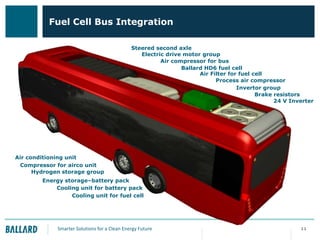

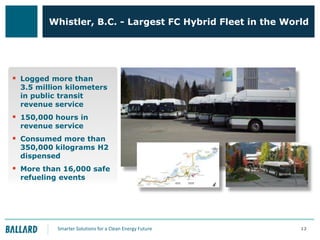

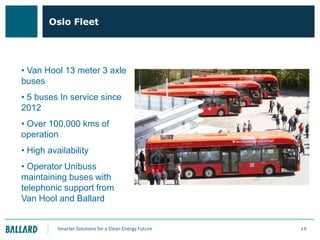

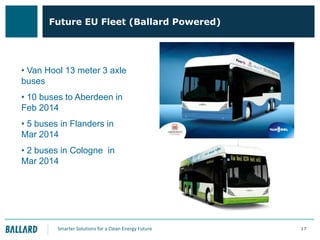

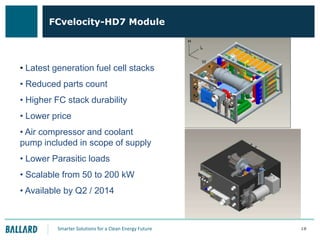

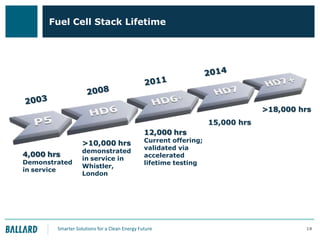

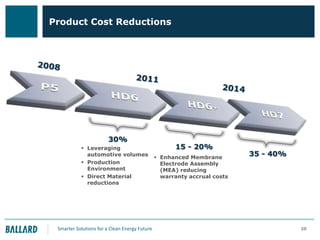

The document discusses advances in fuel cell technology for hybrid transit buses. It provides information about Ballard Power Systems, a leader in PEM fuel cells, including their intellectual property portfolio, products, engineering services, and experience deploying over 45 fuel cell buses worldwide. Key points include reductions in emissions from fuel cell buses compared to diesel, advantages of fuel cells for buses, and Ballard's work to increase power density, lifetime, and reduce costs of their fuel cell modules and stacks for commercial bus applications.