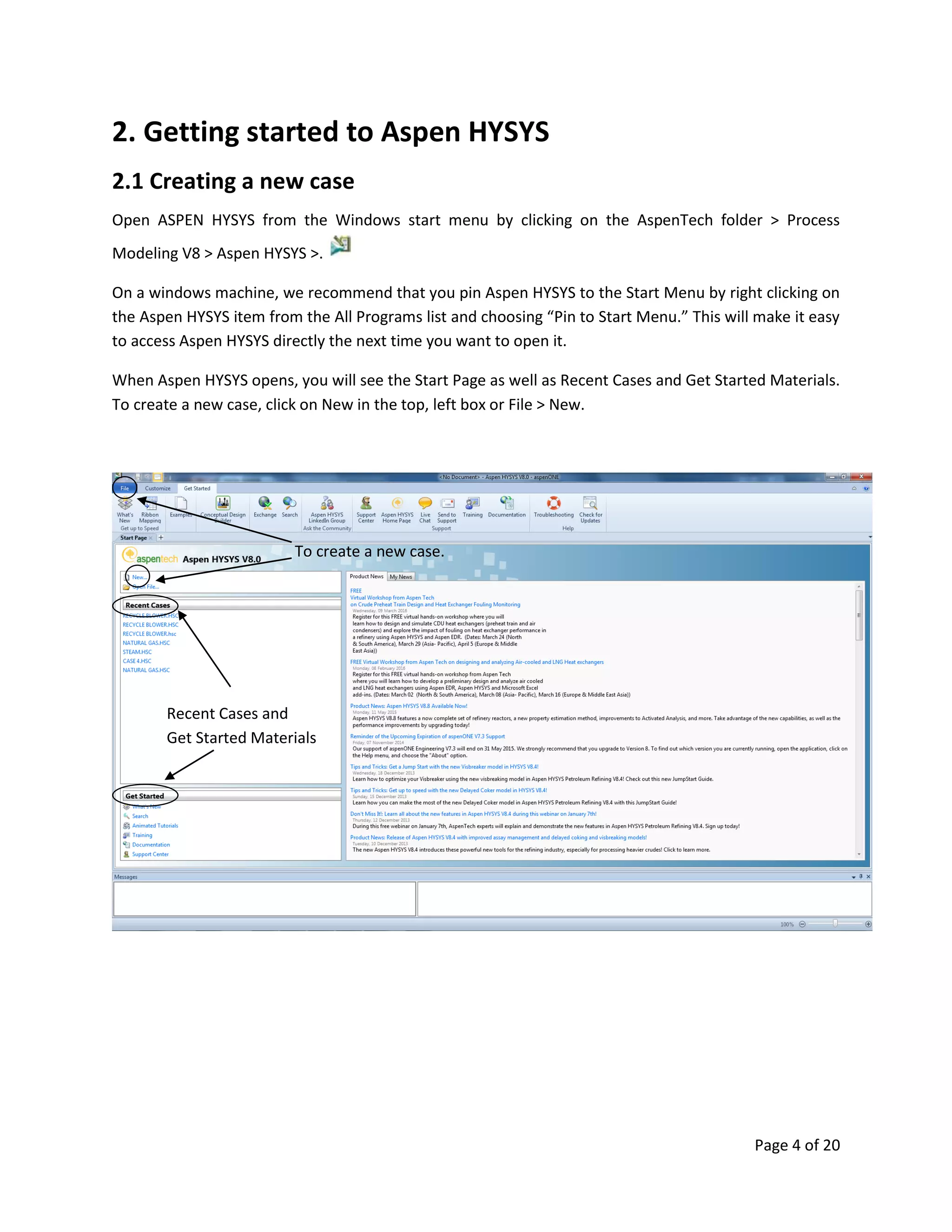

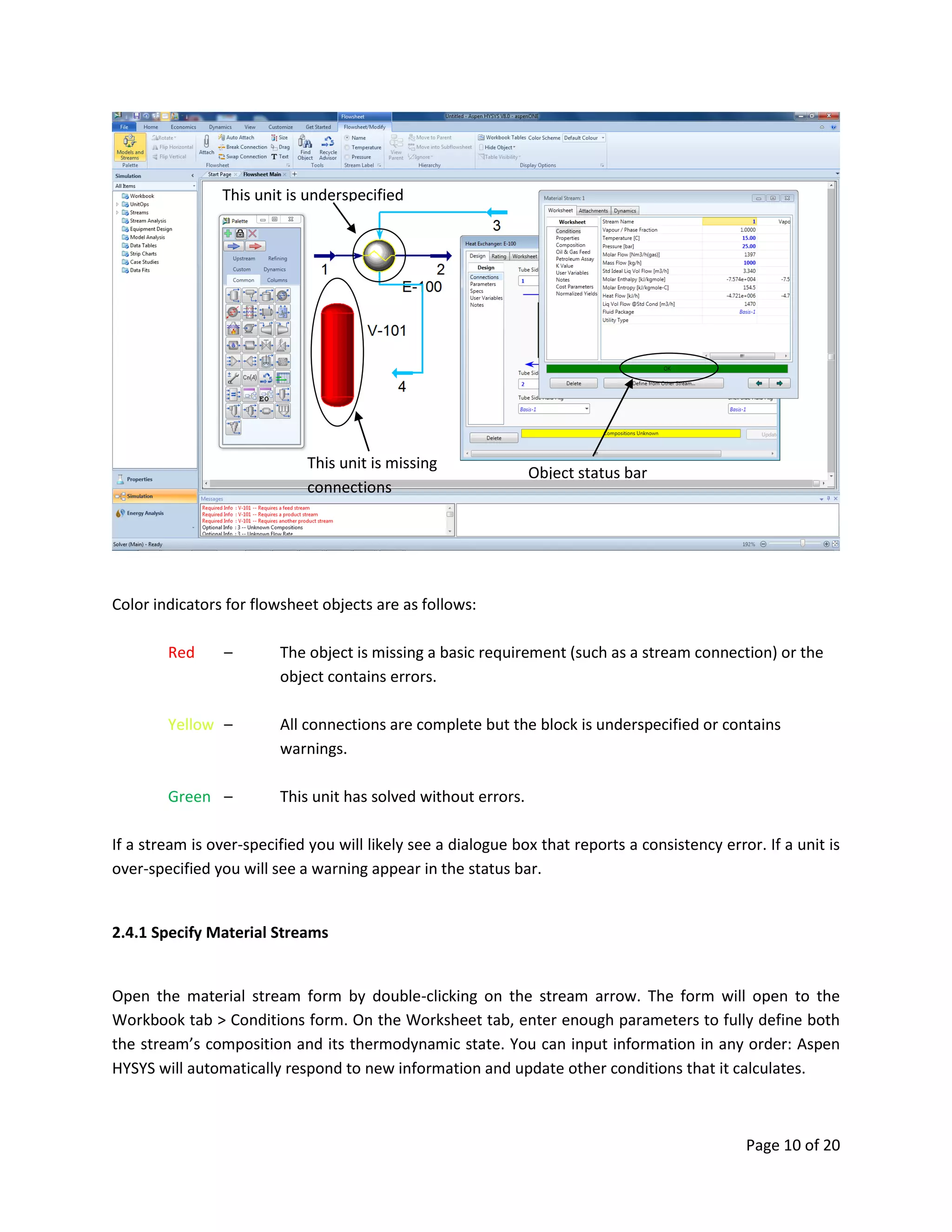

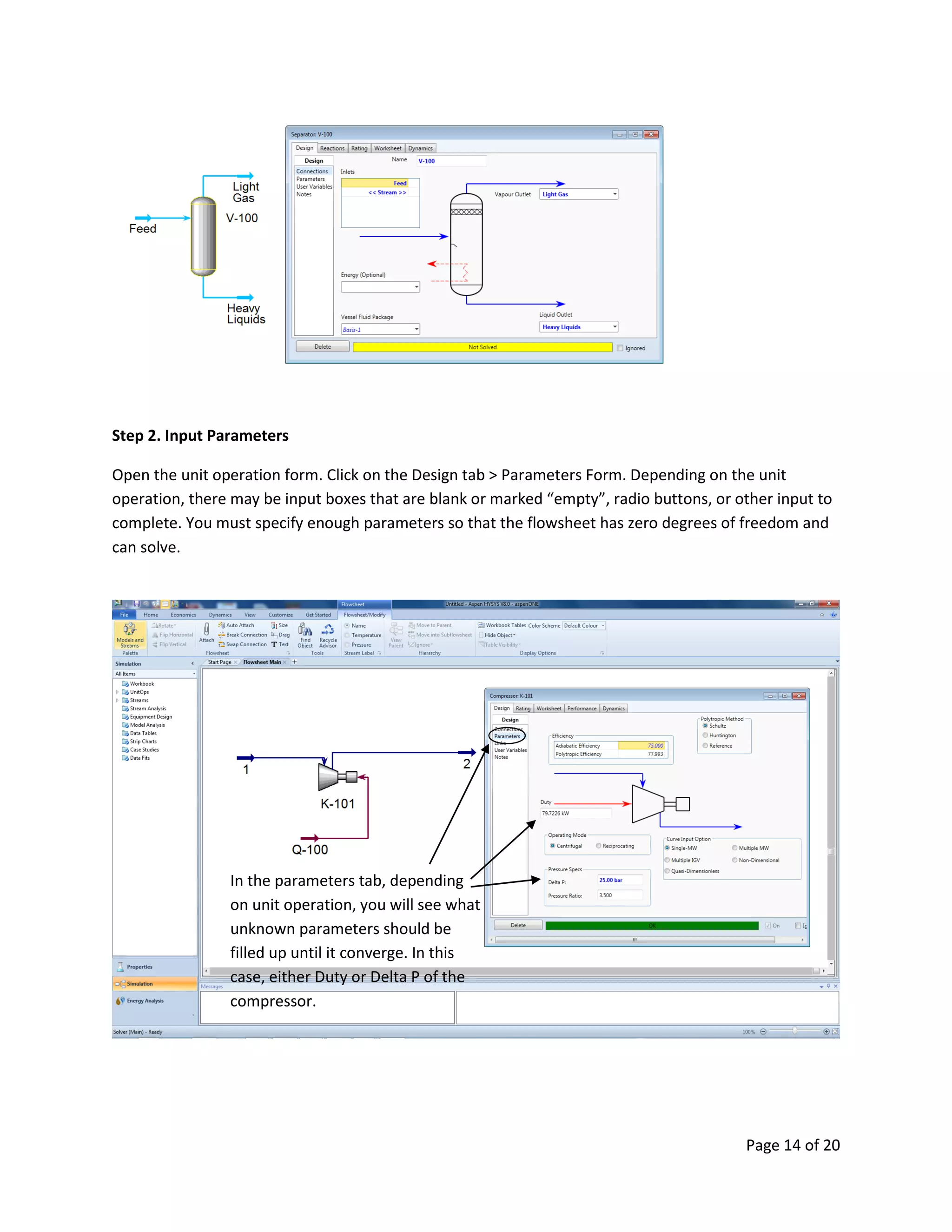

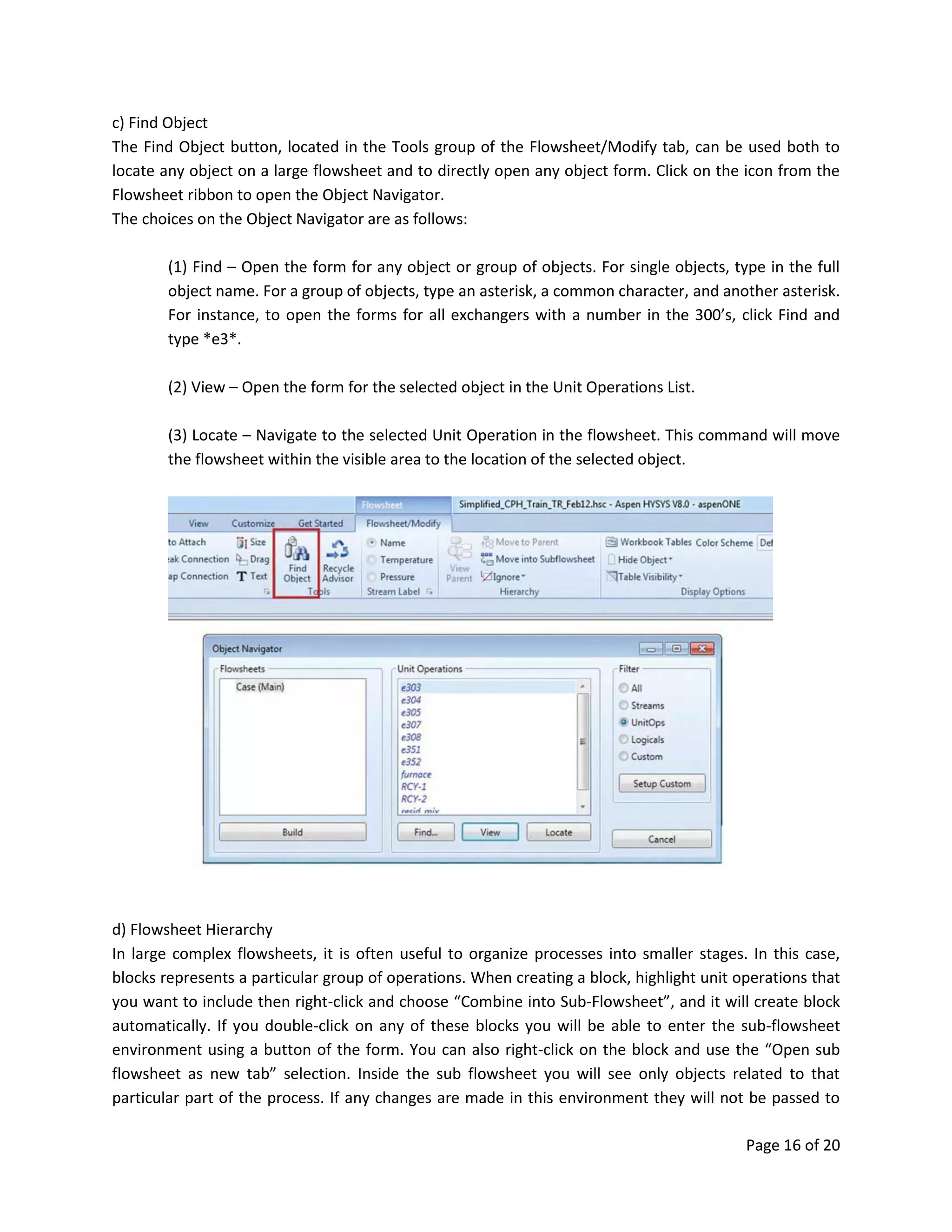

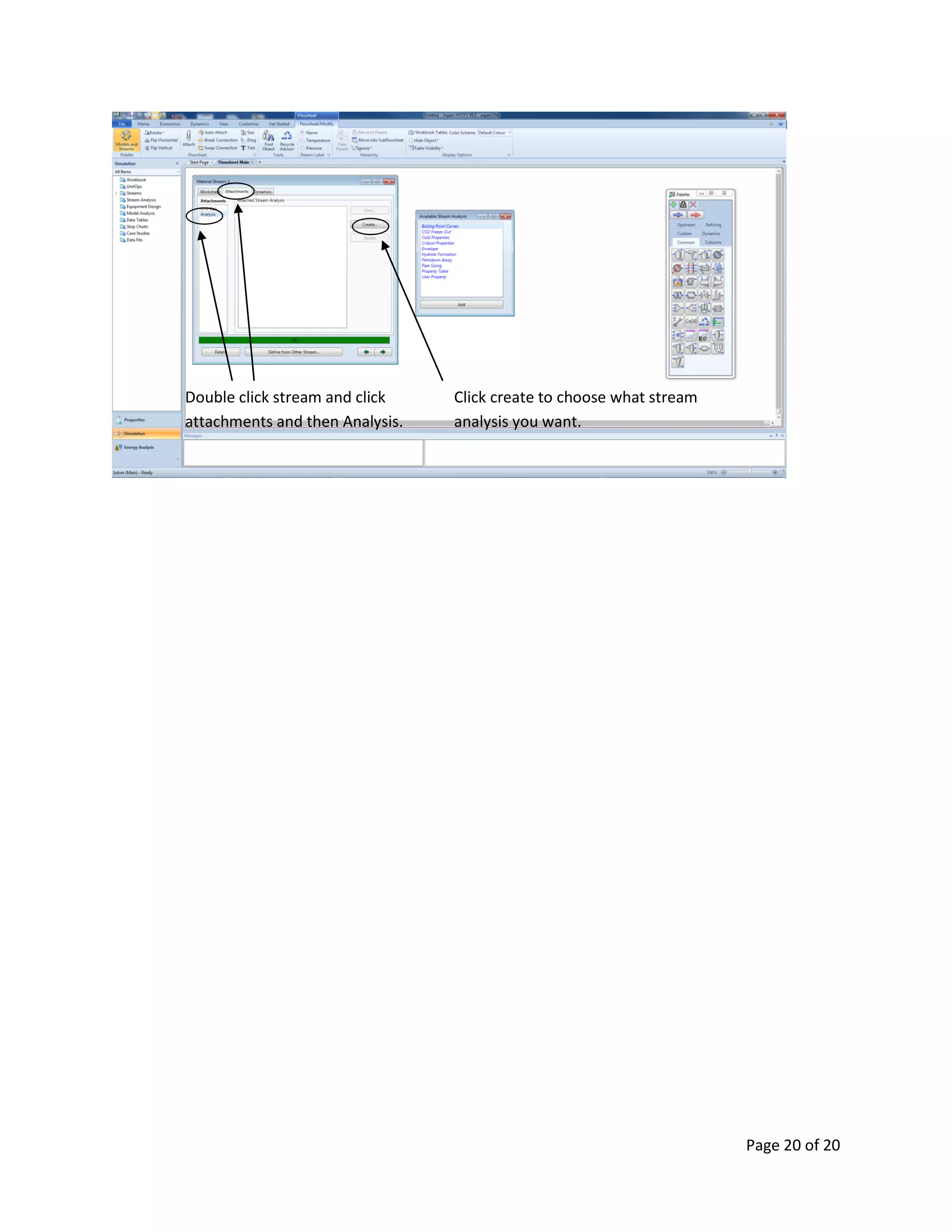

This document provides guidance on using Aspen HYSYS software for process simulation. It outlines how to create a new case, set up component lists and fluid packages, and build a process model. Key steps include adding material and unit operation objects to the flowsheet from the model palette, specifying stream conditions and unit parameters, and using controls to connect objects and navigate the simulation environment. The document also introduces utility analysis functions for examining stream properties over various conditions.