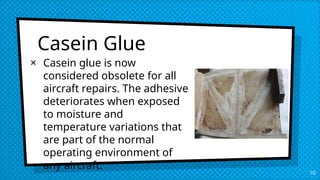

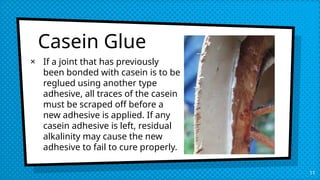

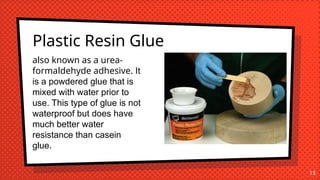

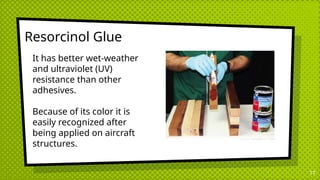

Ramp safety is a critical issue in the aviation industry due to the complex interactions among various personnel and equipment in the airport ramp area. The document discusses the importance of open reporting of safety issues to prevent accidents and provides an overview of different types of adhesives used in aircraft repairs, emphasizing that certain adhesives, like casein and plastic resin glues, are now considered obsolete. It also defines key terms related to adhesive bonding processes, highlighting the need for proper application to ensure durability and efficacy.