IMPLICATIONS OF UAVS FOR AUTONOMOUS TRACTOR DEVELOPMENT

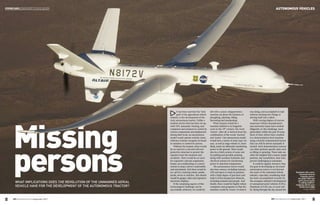

- 1. what IMPLICATIONS does the revolution of tHE UNMANNED AERIAL VEHICLE have FOR THE development of the AUTONOMOUS TRACTOR? Missing persons It has been said that the ‘holy grail’ of the agricultural vehicle industry is the development of the truly autonomous tractor. Unlike a modern tractor that has been set up with GPS, automatic steering, and computers and actuators to control its various components and implements during field work, an autonomous model would operate entirely alone, without a human occupant on board to monitor or control its actions. Without the human, there would be no need for a cab and roll-over protective structure to protect the operator from the elements and accidents. There would be no need for expensive cab/seat suspension, heater, air-conditioning or a stereo system to keep a driver comfortable and entertained. And there would be no call for a steering wheel, pedals, knobs, levers or switches. Also absent would be gauges, dials and expensive electronic displays. If the remaining aspects of this technological challenge can be successfully achieved, we would be left with a smart, stripped-down machine all about the business of ploughing, planting, tilling, harvesting and transporting. What remains would be a machine faithful to its linguistic roots in the 19th century: the word ‘tractor’, after all, is derived from the combination of the words ‘traction’ and ‘motor’. Our autonomous model would have a motor of some type, for sure, as well as large wheels or, more likely, tracks for efficiently transferring power to the ground. There would also be a hitch system of some sort for pulling and possible pushing, along with auxiliary hydraulic and electrical systems for transferring power to attached components. The autonomous tractor would also have sensors, including cameras, GPS and lasers to track its position with a high degree of precision and help it avoid unexpected obstacles, including animals and people. And finally, there would be highly robust computers and programs so that the machine would be ‘aware’ of what it was doing, and accomplish its task without running into things or driving itself into a ditch. With varying degrees of success, numerous vehicle manufacturers and university teams have worked diligently on this challenge, most particularly within the past 10 years. Most of their efforts have resulted in a demonstration-level machine using a heavily instrumented tractor that can still be driven manually if needed. Such demonstration tractors can often perform specific tasks such as tilling or spraying. These tasks are often the simplest that a tractor might perform, but nonetheless, they have proved challenging to automate. It could be argued, however, that the goal of developing an all-round autonomous tractor is not beyond the reach of the industrial vehicle industry, especially considering what has been accomplished recently by the aerospace industry’s development of unmanned aerial vehicles (UAVs). Hundreds of UAVs are, or soon will be, flying through the sky around the 5352 iVTInternational.com September 2011 iVTInternational.com September 2011 steven casey, ergonomic systems design AUTONOMOUS VEHICLES XXXXXXXX: xxxxxxxxxxx Equipped with a pod- mounted infrared imaging sensor, the Altair UAV was particularly useful in aiding wildfire- mapping efforts over California in 2006 Image: NASA

- 2. world, travelling in three dimensions, not just two, and autonomously performing all manner of tasks just as complicated – if not more so – than those performed by a farm tractor. So let’s review the characteristics and capabilities of some successful UAVs, contrast their capabilities with one another, and add a little speculation on what all this might mean to the development of the truly autonomous tractor. Partial versus full automation New-fangled technologies once seen as unnecessary or frivolous can ultimately prove to be well worth the cost. For example, GPS technology first made its mark in agriculture with the development of steering lightbars placed ahead of the driver to help him steer more accurately through the field. “Who,” it was widely believed at the time, “could not steer an ordinary tractor straight after a few hours of practice?” Although quite simple in nature, lightbars ultimately proved to be reasonably popular. Owners learned that they could steer more precisely with the aid of these devices – they lessened crop damage and reduced unnecessary overlap during tillage and spraying. Now they have been superseded by autosteer and automatic control of complex implement functions based on GPS and crop position. Sprayers can be programmed to turn off and on automatically, implements can be raised and lowered without moving a finger, and pumps started and stopped by the computer. The job of the operator has changed from that of a controller to that of a planner, implementer and monitor. The bottom line associated with the use of GPS-based farm tractor automation is that field work can become considerably more accurate. Autosteer systems, coupled with automated controllers, can reduce the typical pass-to-pass overlap of 8- 10% to near zero. This means 10% less material applied to the field, 10% less distance travelled, 10% less fuel consumed, and 10% less of the operator’s (and machine’s) time. What remains, of course, is to completely remove the operator from the vehicle. Theoretically, at least, the labour savings alone could make up for the costs of the added technology, especially once it has been perfected and mass-produced. The economic prospects become even better when everything on a tractor associated with the needs of a ride-along operator (or monitor) is removed. Such a machine could become more fuel efficient, lighter in weight, and, in some ways, even more versatile than its manned counterpart. MAIN IMAGE: Altair control station ABOVE: Portable control trailer for the Predator AUTONOMOUS VEHICLES iVTInternational.com September 2011 55

- 3. UAVs and UASs While a UAV may be ‘unmanned’, the unmanned aerial system (UAS) of which it is a part is not at all autonomous. In fact, depending on the complexity and function of the UAV, the UAS may require not only one ground operator but sometimes many operators and many dozens of support personnel. UAS missions can include electronic attack, close air support, defence suppression, targeting, reconnaissance, aerial refuelling and supply. Most recently, high-altitude UAVs with long dwell times have been studied for their potential as remote orbiting sensors in a ballistic missile defence system, thereby extending a monitored area well beyond the reach of ground- or sea-based radars. Two of the smaller UAVs are the RQ-2 Pioneer and the RQ-7 Shadow. Weighing 205kg and 4.3m in length, the Pioneer was jointly developed by the US and Israeli militaries. It is launched by rocket assist while shipboard, from a runway, or by a catapult when a runway is not available, and is retrieved with a net (when shipboard) or with arresting gear while on the ground. Its five- hour flight time makes it useful for reconnaissance missions and gunnery spotting. Pioneers are controlled via a ground-based pilot via video feed and real-time line-of-sight datalink. A ground- or ship-based pilot ‘flies’ the aircraft and is supported by numerous launch, recovery and other support personnel. The USA phased out use of the Pioneer in 2007, following it with the RQ-7 Shadow. Like the Pioneer, it is primarily used for reconnaissance. In the US military, a Shadow platoon typically consists of four air vehicles, two ground control stations, and supporting ground transport vehicles. The latest version has a wingspan of 6.1m and an endurance of nearly nine hours. Also, based on high accident rates during landings of the simplistic Pioneer, it was fitted with an automated landing system. Perhaps the two most widely known UAVs are General Atomics Aeronautical’s Predator and Reaper. The former, originally designed for deployment in ‘moderate risk areas, unsecured airspace, open ocean, and bio- or chemical-contaminated environments’, can fly autonomously or via the commands of a ground- based pilot connected via a direct radio link or satellite hook-up. It has a wingspan of 14.6m, a service ceiling of 25,000ft, and endurance of 24 hours. It is this extended dwell time that has made it a useful tool across many military and civil applications. Predators have been used for earth science research, surveying wildfires, and anti-piracy patrols over the Indian Ocean. Developed at its own expense, General Atomics Aeronautical’s follow-on to the Predator – the appropriately named Reaper – is essentially a more powerful, faster, larger, and, if so fitted, armed version of the Predator and can stay airborne for up to 24 hours. It has a wingspan of 20.12m and a maximum altitude of 50,000ft. Like the Predator, it can be flown by the ground-based pilot via a direct radio link when within line-of-sight, or, more commonly, by a distant ground-based pilot linked by satellite. The remote pilot can take direct control of the craft via joystick, but most commonly, it flies itself based on a transmitted flight AUTONOMOUS VEHICLES main image: General Atomics’ Euro Hawk – a close relative of the Global Hawk ABOVE: Mission control station for the Predator iVTInternational.com September 2011 57

- 4. plan. It is typically launched by an airport-based crew, with control then handed to a mission team until it is ready to land 24 hours later. The main ground control station consists of a pilot position, payload operator position, mission planning and communications station, data exploitation position, and synthetic aperture radar station. Multiple crews are necessary due to the long duration of flights. More than 400 Predators and Reapers have been ordered around the world, including the Altair, a climate- and marine- monitoring variant flown by NASA. But the current leader in UAVs is Northrop Grumman’s RQ-4 Global Hawk. This jet-powered craft looks a bit like the venerable U-2 spy plane, largely because its mission is broadly similar. Indeed, the U-2 is being retired, to be replaced by the RQ-4. Controlled via satellite link from a remote location, Global Hawk’s flights are fully pre-programmed, but a ground pilot can take control if necessary. Autonomous flight control systems and GPS control take-offs and landings; the latter handled with a line-of-sight datalink. Operations are handled by a distant Mission Control Element, often on the other side of the planet. Global Hawk has an operational ceiling of 65,000ft and an endurance of 36 hours – but though it may be unmanned, dozens, if not hundreds, of individuals are required to carry out each mission. Yay or Nay? Technologically impressive? Without a doubt. Staggeringly expensive? Unbelievably so! A hint of the future for the autonomous tractor? In some ways ‘Yes’ and in some ways ‘No’ – see ‘Food for thought’ below. In the ‘Yes’ column, there are a number of aspects that may indeed foretell the path forward. The first is that what has been achieved was basically thought next to impossible just a few years ago. Global Hawk, for example, can autonomously take returning to the barn 24 hours after it set out to spray hundreds of acres, precisely navigating its own way, and applying exactly the right amount of material only where it is needed, day and night. And it would perform with exactly the same degree of precision and speed at the end of its long day as it did at the beginning. A final promising pointer relates to whether the job is ‘dull, dirty or dangerous’, a phrase that has justified the use of UAVs for many military missions. The same could be said for an autonomous tractor, especially with regard to exposure to spraying operations. Operating a tractor for a long day can have intrinsic rewards for some – but few who have had the experience can deny the potential for ‘dull and dirty’ as well. iVT Food for thought? Considering that the main point of the truly autonomous tractor is to eliminate – or at least substantially reduce – the manpower required to operate a tractor during repetitive field work, in this regard the current world of UASs is not a very good model of where autonomous agricultural or industrial vehicles might end up. Modern UAVs such as Global Hawk represent a staggering technological capability, but also require staggering levels of manpower to operate and maintain the systems. These are essentially military systems, developed with massive budgets and deployed in all corners of the globe at great expense by legions of highly skilled people. One vision for agriculture is of a machine that has the operational autonomy of a craft such as Global Hawk, but without the sizeable support staff and massive overheads. Once it has been fitted with its working implement or tool, the autonomous tractor would find its way out to the field by itself, arrive at its assigned place of work, do its job for hours on end, and continue the process around the clock or until it was in need of refuelling or human attention. The absence of sunlight or the arrival of heavy fog wouldn’t slow it down. It would alert its human master if it had any special needs or instructions, but would otherwise just go about its assigned task. A second, but related vision, is of a fleet of such machines, all controlled by a small team of operators and maintainers in a fixed location. Other than a few hours of maintenance and preparation each day, the autonomous tractors would toil away in the field under the watchful eye of a human monitor. Combined, the machines and their few human masters would accomplish far more work than a fleet of traditional tractors. off, fly halfway around the world in any weather (day or night), perform a complex mission, land itself a day and a half later and park at the end of the taxiway, waiting for a tow to the hanger. So it is perhaps not too much of a stretch to envision a farm tractor with equivalent, but more down-to-earth, capabilities. We can also tick the question of endurance. UAVs have achieved such success partially because of extensive flight times, so it is easy to visualise an autonomous agricultural vehicle AUTONOMOUS VEHICLES iVTInternational.com September 2011 left: The Global Hawk is the ultimate in UAVs NEXT ISSUE So how would you go about designing a user interface for an automated or remotely operated vehicle? Steve Casey provides some hints in our forthcoming Off- Highway Annual 58