The document provides comprehensive information on Tire Pressure Monitoring Systems (TPMS), including their benefits, legislation requirements, and operational details of a TPMS tool. It outlines safety precautions for using the tool, descriptions of its functionalities, specifications, and system settings. Additionally, the document contains diagnostic procedures and maintenance guidelines for effective utilization of TPMS technology.

![2

2. General Information

2.1 TPMS system review

A tire pressure monitoring system (TPMS) is an electronic system

designed to monitor the air pressure inside the pneumatic tires on

various types of vehicles. TPMS report real-time tire-pressure

information to the driver of the vehicle, either via a gauge, a

pictogram display, or a simple low-pressure warning light. TPMS

can be divided into two different types — direct (dTPMS) and

indirect (iTPMS). TPMS are provided both at an OEM (factory)

level as well as an aftermarket solution.

2.2 TPMS Legislation

In the United States, the United States Department of Transportation

(NHTSA) released the FMVSS No. 138, which requires an

installation of a Tire Pressure Monitoring System to all new

passenger cars, multipurpose passenger vehicles, trucks, and buses

that have a gross vehicle weight rating (GVWR) of 4,536 kg

(10,000 lbs.) or less, except those vehicles with dual wheels on an

axle, as of 2007. In the European Union, starting November 1, 2012,

all new models of passenger cars must be equipped with a TPMS,

with even tighter specifications that will be defined by the UNECE

Vehicle Regulations (Regulation No. 64). From November 1, 2014,

all new passenger cars sold in the European Union must be equipped

with TPMS. On July 13, 2010, the South Korean Ministry of Land,

Transport and Maritime Affairs announced a pending partial-revision

to the Korea Motor Vehicle Safety Standards (KMVSS), specifying

that "TPMS shall be installed to passenger vehicles and vehicles of

GVW 3.5 tons or less, ... [effective] on January 1, 2013 for new

models and on June 30, 2014 for existing models". Japan is expected

to adopt European Union legislation approximately one year after

European Union implementation. Further countries to make TPMS

mandatory include Russia, Indonesia, the Philippines, Israel,

Malaysia and Turkey.](https://image.slidesharecdn.com/autelts601maxitpms-190114154723/85/Autel-TS601-User-Manual-4-320.jpg)

![26

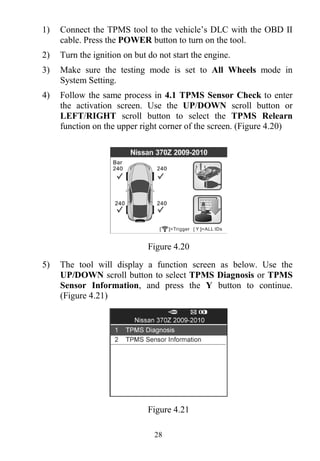

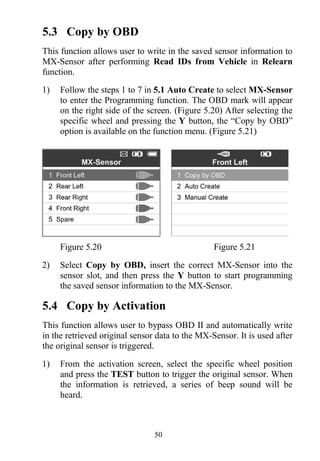

[Pos] – Indicates the wheel sensor position.

[ID-H/D] – Shows sensor ID data.

[KPa/Psi/Bar] – Indicates tire pressure.

[°C/°F] – Indicates tire temperature.

[BAT] – Indicates battery condition.

[Mode] – Defines tire sensor working mode or status.

[Modulation] – Indicates sensor signal amplitude.

B. Select by Latest Test

This function allows you to review the last tested sensor data and

activate the sensor by using the wave signal of the latest trigger event,

which is very convenient and useful for technicians to wake up

sensors of the same vehicle.

1) Use the UP/DOWN scroll button and LEFT/RIGHT scroll

button to select Latest Test from Main Menu (Figure 3.1).

2) An activation screen with the previously activated sensor

information will show up (Figure 4.17). Use the UP/DOWN or

LEFT/RIGHT scroll button to select the desired wheel, and

press the TEST button to reactivate the sensor, or press the Y

button to view all detailed sensor data (Figure 4.18).

Figure 4.17](https://image.slidesharecdn.com/autelts601maxitpms-190114154723/85/Autel-TS601-User-Manual-28-320.jpg)

![53

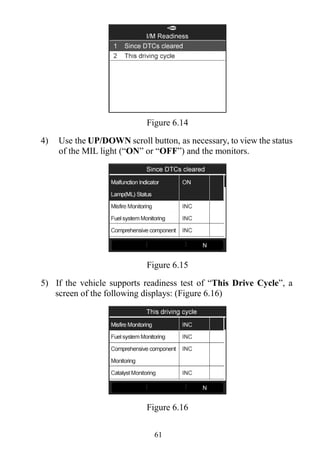

6. OBDII Diagnostics

The OBD II Diagnostics function is a fast-access option that allows

you to carry out a quick test on the engine system of OBD

II-compliant vehicles.

When more than one vehicle control module is detected by the scan

tool, you will be prompted to select the module where the data may

be retrieved. The most often to be selected are the Power-train

Control Module [PCM] and Transmission Control Module [TCM].

CAUTION: Don’t connect or disconnect any test equipment with

ignition on or engine running.

1) Turn the ignition off.

2) Locate the vehicle’s 16-pin Data Link Connector (DLC).

3) Plug the scan tool cable connector into the vehicle’s DLC.

4) Turn the ignition on. Engine can be off or running.

5) Turn on the scan tool. Select OBD II from the Main Screen.

(Figure 3.1)

6) Press the Y button to wait for the Menu to appear. A sequence

of messages displaying the OBD II protocols will be observed

on the display until the vehicle protocol is detected.

If the scan tool fails to communicate with the vehicle’s ECU

(Engine Control Unit) more than three times, a “LINKING

ERROR!” message shows up on the display.

Verify that the ignition is ON.

Check if the scan tool’s OBD II connector is securely

connected to the vehicle’s DLC.

Verify that the vehicle is OBD II compliant.

Turn the ignition off and wait for about 10 seconds. Turn the

ignition back to on and repeat the procedure from step 5.

If the “LINKING ERROR” message does not go away, then

there might be problems for the scan tool to communicate with](https://image.slidesharecdn.com/autelts601maxitpms-190114154723/85/Autel-TS601-User-Manual-55-320.jpg)

![75

Figure 9.2

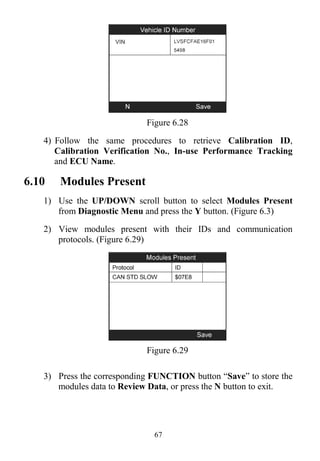

2) Enter your Autel ID and password and wait for the Update

window to display. If you forget your password unintentionally,

you may always click the [Forget Password?] to link to our

website and get your password back.

3) In the Update window, select the items you want to install.

Usually, you should install all available updates.

Figure 9.3

Generally there are two ways to update programs:

Batch Updating

1) Select the programs that you would update by clicking on the

check boxes next to those items. Then click the Update

Selected Items button on the right side of screen. Or](https://image.slidesharecdn.com/autelts601maxitpms-190114154723/85/Autel-TS601-User-Manual-77-320.jpg)

![76

2) Click on the Select All checkbox on the right side of screen and

all updatable items will be selected automatically. Then click

the Update Selected Items button on the right side of screen.

3) Check the updating process by observing the upper left progress

bar [Downloads] and upper right progress bar [Installs]. You

may also find progress information in the Status column of

updated items.

4) When the downloading is completed, the downloaded programs

will be installed automatically. The new version will replace the

old version.

5) Anytime you could click the Pause button on the right side of

screen to suspend all progresses.

6) To resume updating process, you may need to select those

suspended items again, and then click the Update Selected

Items button. The progress will resume from the break point.

Single Updating

1) Find out the desired updating item and click the Install button

in the same line, and the Install button changes to Pause at the

same time.

2) Check the updating process by observing the upper left progress

bar [Downloads] and upper right progress bar [Installs]. You

may also find progress information in the Status column of

updated items.

3) Anytime you could click the Pause button in the line to suspend

this progress.

4) To resume updating process, click the Install button in the line

again. The progress will resume from the break point.

5) When the downloading is completed, the downloaded program

will be installed automatically. The new version will replace the

old one.

6) Once the update is complete, disconnect the tool from the](https://image.slidesharecdn.com/autelts601maxitpms-190114154723/85/Autel-TS601-User-Manual-78-320.jpg)