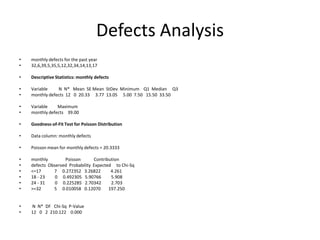

The document outlines an ATM improvement project with the goals of reducing costs from poor quality software and improving the delivery and implementation of ATM software. Currently, defects cost over $183 million per year for one major customer. The project aims to reduce the average monthly defects from 20 to 5 through increased system testing, improved communication between users and developers, and monthly defect meetings, saving an estimated $137 million annually.