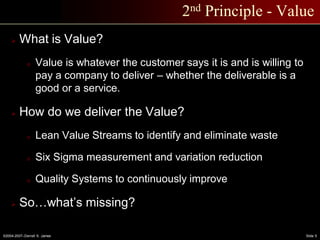

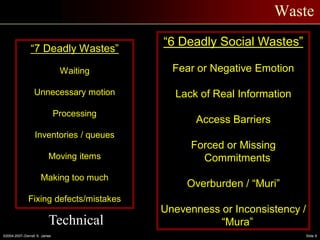

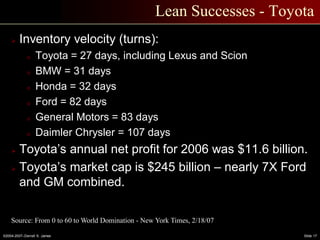

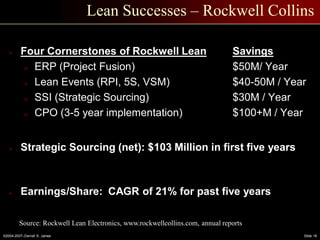

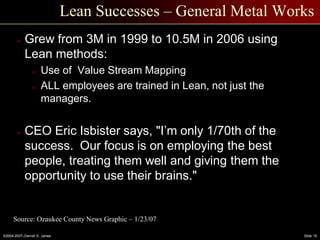

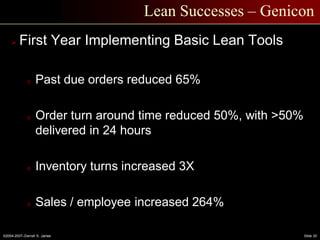

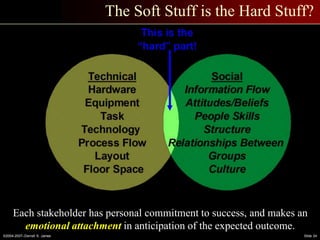

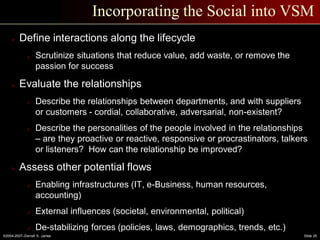

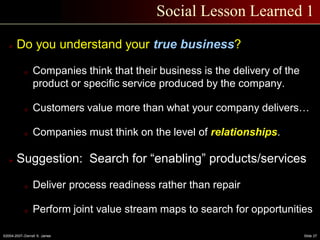

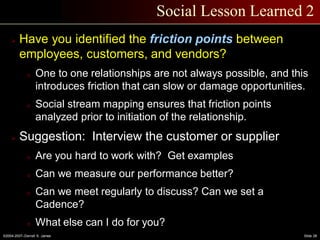

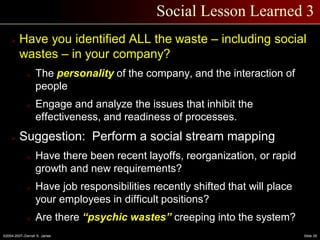

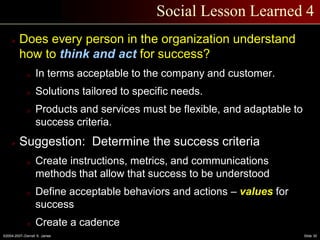

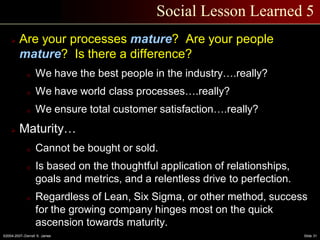

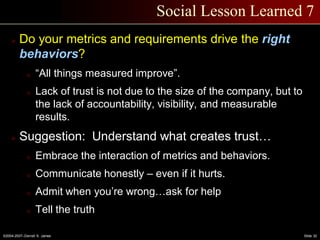

This document contains slides from a presentation by Derrell James on applying lean principles to businesses. It discusses key lean concepts like eliminating waste and friction. It provides examples of successful lean transformations at companies like Toyota, Rockwell Collins, and General Metal Works. It also outlines common mistakes to avoid, like not involving employees in changes or failing to address social and cultural factors. The presentation emphasizes the importance of understanding value from the customer's perspective and achieving maturity in processes and people.