1. The document summarizes a numerical investigation of a two-phase jet pump with and without a swirling primary jet.

2. The study models different nozzle profiles, including circular, elliptical, and conical shapes, to analyze how swirling the primary jet affects pump performance characteristics like efficiency.

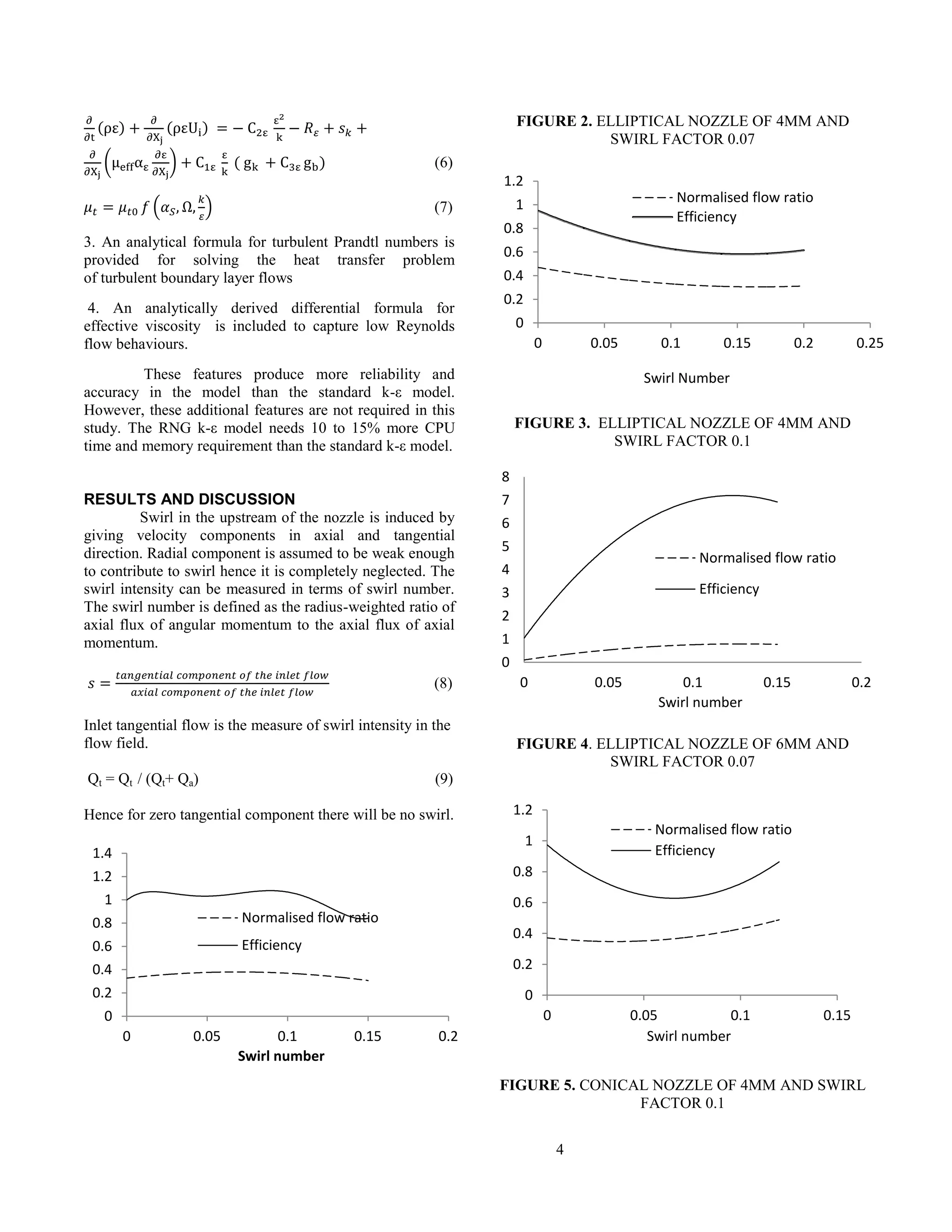

3. The results show that introducing a moderate amount of swirl can increase the secondary fluid entrainment and overall efficiency, but higher swirl intensities decrease performance. The optimal swirl depends on factors like the nozzle diameter and shape.

![2

yp Contribution of the fluctuating dilatation in

compressible turbulence to the overall dissipation

rate

μt0 Turbulent viscosity calculated without the swirl

modification

Ω Swirl number

αs Swirl constant value which can be selected on the

basis of swirl intensity ranging from moderate to

high value

INTRODUCTION

A high-pressure fluid (motive fluid) with very low

velocity at the primary inlet is accelerated to high velocity

jet through a converging nozzle for the liquid jet pump. A

wide range of investigations are carried out globally to

develop energy efficient desalination techniques that

induce negligible environmental pollution. Vacuum inside

the desalination system was to be achieved using the

designed two phase jet pump .Since the two-phase jet

pump is the heart of the system, the present numerical

approach helps to analyse and optimize the jet pump with

the effect of swirl in primary stream inside nozzle and how

it affects the downstream flow. Many authors have

conducted the studies on various evolutionary designs of

ejectors several years ago. The application of the liquid jet

gas pump for air and vapour removal from steam

condensers and pump casings was reported in various

German and Russian papers, beginning with Hoefer [1].

Several investigators later proposed various enhancement

in existing ejectors for getting better performance. Design

analysis of pumps that uses liquids of low viscosity have

been studied by Gosline and O’Brien [2]. Their studies

promote self entrainment of viscous fluids and two

component entrainment when the two fluids are liquids of

different densities.

Many researchers extended the work of these

pioneers contributing their own suggestions and also

carried out valuable experiments to determine the

conditions at which improvements can be achieved.

Martinelli [3] et al. reported that increase in secondary air

can be achieved by increasing pressure of fluid at primary

side. Muller [4] whereas performed studies in existing

designs and concluded that performance can be enhanced

by 37% which was reportedly the maximum efficiency. He

concluded that when the setback distance i.e, the distance

between nozzle exit and mixing chamber entry length is

equal to driving nozzle diameter and also the least angle of

the diffuser will help in enhancing efficiency of jet pump.

Pfliedderer [5] proposed that the pressure ratio

and air flow rate are independent of each other. Stepanoff

analyzed various jet pumps models and proposed a jet

centrifugal pump system. There were studies on ejectors

with multi hole nozzle . Gopichand [6] confirmed that

single nozzle is better than multiple nozzle. Experimental

investigation on various ejector geometries is carried out

by Havelka et al. [7] carried out experimental studies with

various designs of ejctorsat different operating conditions.

There were already various suggestions available in nozzle

profiles and one of those studies confirmed that elliptical

nozzle can be proved to be better by Gutmark and

Grinstein [8] for better mixing of two streams and fanning.

Similar studies were done by Sudevan [9] employing a

multi hole nozzle to optimize mixing tube length as it has

also played a major role in ejector performance. Later,

Vishnu [10] did studies on elliptical nozzle along with

conical and circular to compare the performance in his

work experimentally. The geometrical design is inspired

from his work Vishnu experiment. It was concluded that

area ratio has major role to play in ejector efficiency than

any other parameter. Reddy and Kar [11] studied the effect

of flow ratio and concluded that if it is equal to unity then

maximum efficiency of system can be achieved. Lesser

area ratio ejectors were also studied by Sangar [12] with

primary fluid as water. Winoto et al. [13] performed one

dimensional theoretical study on water- air ejector system.

Also to support his studies, he carried out experimental

work on water jet pump. And concluded that a nozzle with

non circular cross section has an impact on nozzle

performance and sharp edges may lower overall efficiency

of jet pump. Narabayashi et al. [14] did experiments as

well as and performed computational fluid dynamics

(CFD) analysis of flow in single and multi-hole nozzle jet

pumps and reported that single hole nozzle works

efficiently for zero set back distance . Also they tried a

different mixing tube with a tapered shape rather than a

traditional straight for enhancing efficiency. According to

their experimental results, five hole nozzle gives performs

ill as compared to single nozzle as in between the nozzle

finger there is more resistance developed. Gresho [15]

numerically optimized mixing throat length for area ratio

of 0.6 by three-dimensional (3-D) using re-normalization

group k-ɛ1 turbulent model. In present time, investigators

and research are attracted towards the swirl activity in

nozzle such studies were carried out by Guillaume and

Judge [16] through their experiments. They reported that at

moderate swirl, the jet pump has shown 4.5% increment in

entrained secondary fluid which leads to 5% increase in

overall efficiency when compared to the same pump

without swirl . Samad et al. [17] and shows that swirl

promotes jet breakup resulting in higher suction rates. He

incorporates swirler of various angle in his experiments.

Although various combination of design prove that

incorporating swirl into a jet pump may increase

performance, Zhou et al. [18], showed numerically that

swirl can be detrimental to pump performance.

Specifically, they used commercial CFD software

FLUENT to model the effect of swirling the primary jet in

a study designed to evaluate the effectiveness of a jet pump

on reducing the infrared signature of the exhaust of a gas

turbine. They found numerically that pump performance

decreased as the swirl angle was increased.](https://image.slidesharecdn.com/ddb93a4d-0a02-4d15-8c77-9d7c6efd7037-150826104259-lva1-app6891/75/Arpita_ISHMT2015-2-2048.jpg)

![3

CFD ANALYSIS OF EJECTOR

The efficiency of the pump can be calculated by using the

flow ratio and head ratio as

(1)

(2)

FIGURE 1. REPRESENTATIONAL VIEW OF

EJECTOR OF JET PUMP

The traditional view of ejector is shown in Figure 1.

Further in current study the profile of nozzle will be

changed to visualise change in flow pattern. The

dimensions of ejector used are shown in Table 1 [10].

In the present study, the CFD software ANSYS Fluent

14.0 has been employed to analyze a two-phase ejector of

jet pump which is supposed to be part of an experimental

set up. It is designed to entrain air from a pressure vessel to

create vaccum. Considering the situation to be an

incompressible, steady flow, the axisymmetric pressure-

based solver has been used. The governing equations for

mass and momentum conservation are given in tensor

notation as

(3)

(4)

TABLE 1. DESIGN PARAMETERS OF NOZZLE

Notation Conical

(mm)

Elliptical

(mm)

Circular

(mm)

Do 4,6,8 4,6,8 4,6,8

Dp 21,21,25 21,21,25 21,21,25

Dmt 10 10 10

Dsec 21 21 21

Lmt 265 265 265

S 20 20 20

Ld 135 135 135

Dd 21 21 21

2°30’ 2°30’ 2°30’

The pressure drop that takes place at various pipe

connections has been neglected. The solver is appropriate

for both lower as well as higher values of Reynolds

number and is applicable for simulating the two-phase flow

of air-water mixture. Pressure velocity coupling offers to

solve the problem in either segregated manner or coupled

manner. The SIMPLE algorithm is followed which solves

equations of velocity and pressure to enforce mass

conservation and to obtain the pressure field. Also, this

solver takes lesser computational time and memory. Spatial

Discretization scheme contains settings that control the

spatial discretization of the convection terms in the

solution equations and here for calculating gradients Least

Squares Cell-Based is used. Standard scheme is taken for

pressure, power law scheme for momentum, swirl velocity,

kinetic energy and turbulent dissipation rate and first order

upwind for volume fraction. The standard interpolation

schemes for calculating cell-face pressures takes lesser

time as compared to power law method. For bubble flow

there are Mixture model and Eulerian model can be used to

solve multiphase flow. Mixture model is based on pressure

solver. The differences in between both is that the mixture

model can be a substitute for the full Eulerian multiphase

model in some cases. A full multiphase model is not as

feasible as mixture model. The under relaxation factor for

pressure and momentum quatities are kept as 0.3 and for

the turbulent quantities 0.6. The solutions were assumed to

have converged for the residual level of 10-4

for continuity,

x-velocity, and y velocity and 10-6

for k -epsilon. For

selecting the turbulent model, one can think of standard k-ε

model which is considered as the simplest “complete

model” of turbulence. It is a model based on model

transport equations for the turbulence kinetic energy (k)

and its dissipation rate (ε), that means, it includes two extra

transport equations to represent the turbulent properties of

the flow. Renormalization-Group (RNG) model is

improved from the standard k-ε model by using a rigorous

statistical technique. It is similar to the standard k-ε model,

but can be proved more beneficial as compared to standard

or realizable k-ε model.

1. It includes extra term in governing equation that

provides better accuracy for rapidly strained flows.

2. The effect of swirl in the form of swirl factor is included

which can be activated for swirl dominated flow condition,

and hence improves the accuracy for swirling and rotating

flows. For strongly swirling flows, however, a higher value

of swirl factor can be used which is st as 0.07 for moderate

swirl by default in the software.

Transport Equations for the RNG k- ε Model

–

(5)](https://image.slidesharecdn.com/ddb93a4d-0a02-4d15-8c77-9d7c6efd7037-150826104259-lva1-app6891/75/Arpita_ISHMT2015-3-2048.jpg)

![5

FIGURE 6. CONICAL NOZZLE OF 4MM AND USING

REALIZABLE

K-Ɛ MODEL

The concept of normalized–flow ratio K was given by

Guillaume and Judge [16]. It compares the performance of

jet pump with and without inclusion of swirl and hence is

one of the performance parameter for determining pump

efficiency.

without swirl

with swirl

/

/

S P

S P

Q Q

K

Q Q

(10)

Since QP is same for both cases, hence

, with swirl

, without swirl

S

S

Q

K

Q

(11)

Figure 2 shows the variation of efficiency and normalized

flow ratio with respect to swirl number in elliptical profiled

nozzle. Initially, the secondary flow decreases but on

giving 9% of axial flow as the inlet tangential flow it

reaches it maximum and further start decreasing. As shown

in Figure 3, on increasing the swirl factor, for the same

cases, from default 0.07 value to 0.1, the secondary

entrainment as well as efficiency of jet pump decreases.

Similar trends were observed in other nozzles also.

Performance curves obtained on employing different

model can be seen in Figure 5 and Figure 6 for conical

nozzle of 4mm throat diameter. An increase in swirl

number can cause a increase in entrainment but further

increase in swirl will cause a depreciation too. This can be

observed from Table 2 where on increasing the tangential

component of flow there is increase in secondary flow but

as swirl intensity is raised by giving swirl factor as 0.1 is

went down. Figure 9 shows a comparative view of flow

pattern on increasing the swirl number. On giving swirl

number upto 0.25 to 0.3 there is an increase in entrainment

and then decreases further causing reverse flow in the

secondary. On observing the Figure 6 similar trend is

observed. For swirl number 0.12 it attains maximum and a

maximum entrainment is thus reported. The vortices

developed enhances the secondary flow and enable better

mixing of fluids. However, turbulent kinetic energy

however decreases on attaining higher swirl number as

shown in Figure 7-8 . A decreasing turbulent intensity does

signifies that the flow becomes less turbulent. It can be

predicted that the velocity fluctuations divided by the

mean velocity decreases. If both values increases, but the

mean velocity increases even more, than the intensity

decreases. Reynolds number is a ratio representing the

relative importance of inertial forces to viscous forces in

the flow. Further wall effects can be studied to get more

realistic view of the flow. This preliminary experiment

shows that the efficiency of a jet pump can be significantly

improved by simply replacing the jet nozzle that has a

round cross section with a jet nozzle that has an elliptical

cross section.

CONCLUSION

It was found that elliptical nozzle with 4mm diameter gives

better efficiency as compared to other nozzle for the same

inlet flow condition. The formation of vortices and their

interaction with walls also plays an important role in

determining entrainment as it influence the mixing of two

phase fluids at downstream. Upon giving 10% to 12% of

axial flow as a tangential flow at the inlet there is a

increase in entrainment by 4 to 7 %. Further based on the

swirl numbers leading to better efficiency swirler can be

designed to validate the results.

FIGURE 5. VELOCITY PROFILE FOR ELLIPTICAL

NOZZLE OF 4 MM

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

0 0.02 0.04 0.06 0.08 0.1 0.12

Swirl number

Efficiency

----- Normalised flow ratio

Position (mm)

VelocityMagnitude(m/sec)](https://image.slidesharecdn.com/ddb93a4d-0a02-4d15-8c77-9d7c6efd7037-150826104259-lva1-app6891/75/Arpita_ISHMT2015-5-2048.jpg)