More Related Content Similar to Arpf cutter. (20) More from Trigonenterprisespvtltd More from Trigonenterprisespvtltd (15) 1. IARPF/ARPF + IABPF/ABPF

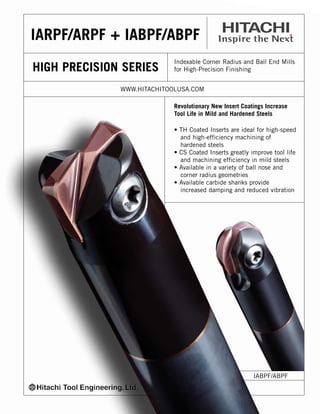

HIGH PRECISION SERIES

Indexable Corner Radius and Ball End Mills

for High-Precision Finishing

WWW.HITACHITOOLUSA.COM

Revolutionary New Insert Coatings Increase

Tool Life in Mild and Hardened Steels

• TH Coated Inserts are ideal for high-speed

and high-efficiency machining of

hardened steels

• CS Coated Inserts greatly improve tool life

and machining efficiency in mild steels

• Available in a variety of ball nose and

corner radius geometries

• Available carbide shanks provide

increased damping and reduced vibration

IABPF/ABPF

2. IARPF/ARPF + IABPF/ABPF

TYPE

PAGE

IARPF/ARPF-S

High Precision Finishing Radius - Regular Length

6

IARPF/ARPF-L

High Precision Finishing Radius - Long Length

7

IARPF + IARPF-WR

High Precision Finishing Radius - Carbide Shank Regular Length

8

IARPF/ARPF-WL

High Precision Finishing Radius - Carbide Shank Long Length

9

ARPF-WE

High Precision Finishing Radius - Carbide Shank Extra Long Length

9

ARPFM

Modular High Precision Finishing Radius

10

INSERTS

High Precision Finishing Radius

11

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

3. IARPF/ARPF + IABPF/ABPF

TYPE

PAGE

IABPF/ABPF-S

High Precision Finishing Ball - Regular Length

12

IABPF/ABPF-L

High Precision Finishing Ball - Long Length

13

IABPF/ABPF-W + IABPF-WR

High Precision Finishing Ball - Carbide Shank Regular Length

14

IABPF/ABPF-WL

High Precision Finishing Ball - Carbide Shank Long Length

15

ABPF-WE

High Precision Finishing Ball - Carbide Shank Extra Long Length

15

ABPFM

Modular High Precision Finishing Ball

16

INSERTS

High Precision Finishing Ball

17

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

4. IARPF/ARPF + IABPF/ABPF

INTRODUCTION

The Precision Finishing Indexable End Mill Series combines high precision inserts with revolutionary new coatings to

provide higher machining efficiency and longer tool life. A variety of inch and metric inserts in both Ball Nose and Corner

Radius styles are available, and holders are stocked in a variety of lengths in either steel or solid carbide shanks.

Both metric ball nose and metric

corner radius style inserts are available

in Hitachi’s revolutionary TH and CS

coatings. The TH coating provides

unrivaled performance in hardened

steels, and the CS coating is ideal for

carbon and alloy steels.

HRC 70

D2 (H) 60

AISI 420

H13 (H) 50

P21 40

AISI 4140 30

AISI 304

H13 (A) 20

D2 (A)

AISI 1049

0

50

(164 sfm)

100

(328.1 sfm)

150

(492.1 sfm)

200

(656.2 sfm)

CUTTING SPEED (m/min)

FEATURES

1.

High Precision Inserts

For Ball Nose Inserts, the insert tolerance on the ball end is ±0.005mm (0.0002) and the set-up accuracy is ±0.01mm

(0.0004). For Corner Radius Inserts, the insert tolerance is ±0.015mm (0.0006) and the set-up accuracy is ±0.02mm

(0.0008).

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

5. IARPF/ARPF + IABPF/ABPF

2.

TH Coated Inserts for High-Speed, High-Efficiency Machining of Hardened Steels

The high hardness and oxidation resistance of the revolutionary TH Coating ensure excellent performance and long tool

life in 45-60HRC hardened steels such as H13, D2, and A2 as well as pre-hardened steels such as NAK80 and CENA1.

High heat resistance makes TH Coated Inserts suitable for dry cutting.

OXIDIZING TEMPERATURE (C°)

1200

TH

1000

TiAIN

800

600

TiN

400

1000

2000

3000

4000

HARDNESS

3.

CS Coated Inserts for High-Efficiency Machining of Carbon and Alloy Steels

Nano-crystal technology helps to reduce the friction-resistance of the coating while maintaining the hardness. This

reduction in friction decreases tool wear and also makes dry cutting possible.

COEFFICIENT OF FRICTION (µ)

1

TiAIN

0.8

TiN

0.6

0.4

CS

0.2

0

1000

2000

3000

4000

HARDNESS

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

6. IARPF/ARPF-S

Corner Radius Style

Regular Length

IARPF/ARPF PRECISION FINISHING SERIES

A

Ød2

R

ØD

lb

Ød1

B

l

l1

lb

ls

L

60

CORNER RADIUS

SEMI-FINISHING

FINISHING

HRC 60

2 FLUTES

R

±0.015

Set-up

±0.010

IARPFS - INCH

Part No.

Flutes

ØD

L

l

l1

lb

ls

Draft Angle

Ød1

Ød2 Type Insert

IARPF06S08

2

0.375

3.937

0.118

0.512

0.984

2.953

5.0°

0.500

0.354

A IZCFW060-Rx.x

IARPF08S08

2

0.500

4.331

0.157

0.591

1.181

3.150

-

0.500

0.480

B IZCFW080-Rx.x

IARPF12S12

2

0.750

5.512

0.236

0.827

2.362

3.150

-

0.750

0.728

B IZCFW120-Rx.x

IARPF16S16

2

1.000

5.906

0.315

0.945

2.756

3.150

-

1.000

0.980

B IZCFW160-Rx.x

ØD

L

l

l1

lb

ls Draft Angle

ARPFS - METRIC

Part No.

Flutes

Ød1

Ød2 Type Insert

ARPF08S12

2

8

100

2.5

10

22

78

9.5°

12

7.5

A

ZCFW080-Rx.x

ARPF10S12

2

10

100

3.0

13

25

75

3.0°

12

9.5

A

ZCFW100-Rx.x

ARPF12S12

2

12

110

4.0

15

30

80

-

12

11.5

B

ZCFW120-Rx.x

ARPF16S16

2

16

130

5.0

17

50

80

-

16

15.5

B

ZCFW160-Rx.x

ARPF20S20

2

20

140

6.0

21

60

80

-

20

19.5

B

ZCFW200-Rx.x

ARPF25S25

2

25

150

8.0

24

70

80

-

25

24.5

B

ZCFW250-Rx.x

Inserts p. 11

Part No.

581-142

104-T10

IARPF08S08

581-143

105-T20

IARPF12S12

581-148

101-T25S

IARPF16S16

581-146

105-T30A

ARPF08S12

581-141

104-T8

ARPF10S12

581-142

104-T10

ARPF12S12

581-143

105-T20

ARPF16S16

581-144

105-T20

ARPF20S20

581-145

101-T25S

ARPF25S25

phone no. 800.333.1514

Wrench

IARPF06S08

Clamp Screw

581-146

105-T30A

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

7. IARPF/ARPF-L

Corner Radius Style

Long Length

IARPF/ARPF PRECISION FINISHING SERIES

Ød2

R

ØD

Ød1

l

l1

lb

ls

L

60

CORNER RADIUS

FINISHING

SEMI-FINISHING

HRC 60

2 FLUTES

R

±0.005

Set-up

±0.010

IARPFL - INCH

Part No.

Flutes

ØD

L

l

l1

lb

ls Draft Angle

Ød1

Ød2 Type Insert

IARPF06S08L

2

0.375

5.906

0.118

0.512

1.969

3.937

2.0°

0.500

0.354

A IZCFW060-Rx.x

IARPF08S10L

2

0.500

6.299

0.157

0.591

2.362

3.937

2.0°

0.625

0.480

A IZCFW080-Rx.x

IARPF12S16L

2

0.750

7.087

0.236

0.827

3.150

3.937

2.0°

1.000

0.728

A IZCFW120-Rx.x

IARPF16S20L

2

1.000

7.874

0.315

0.945

3.543

4.331

2.0°

1.250

0.980

A IZCFW160-Rx.x

ARPFL - METRIC

Part No.

Flutes

ØD

L

l

l1 lb

ls

Draft Angle

Ød1

ARPF08S12L

2

8

130

2.5

10

50

80

3.0°

12

ARPF10S16L

2

10

150

3.0

13

50

100

4.5°

ARPF12S16L

2

12

160

4.0

15

60

100

2.0°

ARPF16S16L

2

16

165

5.0

17

65

100

ARPF20S20L

2

20

180

6.0

21

80

100

ARPF25S25L

2

25

200

8.0

24

90

110

Ød2 Type Insert

7.5

A ZCFW080-Rx.x

16

9.5

A ZCFW100-Rx.x

16

11.5

A ZCFW120-Rx.x

-

16

15.5

B ZCFW160-Rx.x

-

20

19.5

B ZCFW200-Rx.x

-

25

24.5

B ZCFW250-Rx.x

Inserts p. 11

Part No. Clamp Screw

Wrench

IARPF06S08L

581-143

105-T20

IARPF12S16L

581-148

101-T25S

IARPF16S20L

581-146

105-T30A

ARPF08S12L

581-141

104-T8

ARPF10S16L

581-142

104-T10

ARPF12S16L

581-143

105-T20

ARPF16S16L

581-144

105-T20

ARPF20S20L

581-145

101-T25S

ARPF25S25L

www.hitachitoolusa.com

104-T10

IARPF08S10L

phone no. 800.333.1514

581-142

581-146

105-T30A

© 2005 Hitachi Tool Engineering, Ltd.

8. IARPF-W / IARPF-WR

Corner Radius Style

Carbide Shank

Regular Length

IARPF/ARPF PRECISION FINISHING SERIES

CARBIDE

Ød2

R

ØD

Ød1

l

l1

lb

ls

L

60

CORNER RADIUS

FINISHING

SEMI-FINISHING

HRC 60

2 FLUTES

R

±0.005

Set-up

±0.010

IARPFW - INCH

Part No.

Flutes

ØD

L

l

l1

lb

ls

Ød1

Ød2 Type Insert

IARPF06S06W

2

0.375

3.937

0.118

0.906

1.378

2.559

0.375

0.366

B IZCFW060-Rx.x

IARPF08S08W

2

0.500

4.331

0.157

1.024

1.772

2.559

0.500

0.492

B IZCFW080-Rx.x

IARPF12S12W

2

0.750

6.299

0.236

0.866

2.165

4.134

0.750

0.728

B IZCFW120-Rx.x

IARPF16S16W

2

1.000

7.087

0.315

0.984

2.500

4.528

1.000

0.980

B IZCFW160-Rx.x

IARPFWR - INCH

Part No.

Flutes

ØD

L

l

l1

lb

ls

Ød1

Ød2 Type Insert

IARPF06S06WR

2

0.375

5.512

0.118

0.906

2.953

2.559

0.375

0.366

B IZCFW060-Rx.x

IARPF08S08WR

2

0.500

5.906

0.157

1.024

3.346

2.559

0.500

0.492

B IZCFW080-Rx.x

Inserts p. 11

Part No.

581-142

104-T10

IARPF08S08W

581-143

105-T20

IARPF12S12W

581-148

101-T25S

IARPF16S16W

581-146

105-T30A

IARPF06S06WR

581-142

104-T10

IARPF08S08WR

phone no. 800.333.1514

Wrench

IARPF06S06W

Clamp Screw

581-143

105-T20

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

9. IARPF/ARPF-WL / ARPF-WE

Corner Radius Style

Carbide Shank

Long Length / Extra Long Length

IARPF/ARPF PRECISION FINISHING SERIES

Ød2

R

CARBIDE

ØD

Ød1

l

l1

lb

ls

L

60

CORNER RADIUS

FINISHING

SEMI-FINISHING

HRC 60

2 FLUTES

R

IARPFWL - INCH

Part No.

Flutes

ØD

L

l

l1

lb

ls

Ød1

±0.005

Set-up

±0.010

Ød2 Type Insert

IARPF06S06WL

2

0.375

7.087

0.118

0.512

1.378

5.709

0.375

0.366

B IZCFW060-Rx.x

IARPF08S08WL

2

0.500

7.087

0.157

0.591

1.772

5.315

0.500

0.492

B IZCFW080-Rx.x

IARPF12S12WL

2

0.750

9.843

0.236

0.827

3.150

6.693

0.750

0.728

B IZCFW120-Rx.x

IARPF16S16WL

2

1.000

9.843

0.315

0.945

3.150

6.693

1.000

0.980

B IZCFW160-Rx.x

ØD

L

l

l1

lb

ls

Ød1

ARPFWL - METRIC

Part No.

Flutes

Ød2 Type Insert

ARPF08S08WL

2

8

130

2.5

18

65

65

8

7.8

B ZCFW080-Rx.x

ARPF10S10WL

2

10

140

3.0

23

75

65

10

9.8

B ZCFW100-Rx.x

ARPF12S12WL

2

12

150

4.0

26

85

65

12

11.8

B ZCFW120-Rx.x

ØD

L

l

l1

lb

ls

Ød1

16

200

5

29

120

80

16

15.8

B ZCFW160-Rx.x

ARPFWE - METRIC

Part No.

Flutes

Ød2 Type Insert

ARPF16S16WE

2

ARPF20S20WE

2

20

250

6

36

150

100

20

19.8

B ZCFW200-Rx.x

ARPF25S25WE

2

25

300

8

41

190

110

25

24.8

B ZCFW250-Rx.x

Inserts p. 11

Part No.

Clamp Screw

Wrench

IARPF06S06WL

581-142

104-T10

IARPF08S08WL

581-143

105-T20

IARPF12S12WL

581-148

101-T25S

IARPF16S16WL

581-146

105-T30A

ARPF08S08WL

581-141

104-T8

ARPF10S10WL

581-142

ARPF12S12WL

581-143

phone no. 800.333.1514

Part No.

Clamp Screw

Wrench

ARPF16S16WE

581-144

105-T20

104-T10

ARPF20S20WE

581-145

101-T25S

105-T20

ARPF25S25WE

581-146

105-T30A

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

10. ARPFM

Corner Radius Style

Modular

IARPF/ARPF PRECISION FINISHING SERIES

L

H

CR

M

C

E

øD

ød1

ød2

A

l

B

60

CORNER RADIUS

SEMI-FINISHING

FINISHING

HRC 60

2 FLUTES

CR

ARPF-M - METRIC

Part No.

Flutes ØD

±0.005

Set-up

±0.010

L

l

Ød1

Ød2

A

B

C

E

ARPFM20

2

20

38

6

10.5

17.8

5.5

19

10

15

M10

M Type Insert

15

ZCFW200-Rx.x

ARPFM25

2

25

38

8

12.5

20.8

5.5

22

10

17

M12

17

ZCFW250-Rx.x

Inserts p. 11

L

ls

φD

φd2

φd1

l2

M

CARBIDE SHANK - METRIC

Part No.

ØD

ASC20-10.5-170-90

ASC20-10.5-220-120

ASC25-12.5-215-115

ASC25-12.5-265-145

M

10.5

M10

12.5

M12

L

l2

ls

Ød1

170

90

80

18

220

120

100

18

215

115

100

23

265

145

120

23

Ød2

Cutter Body

20

Ø20

25

Ø25

Part No.

ARPFM20

phone no. 800.333.1514

581-145

101-T25S

ARPFM25

10

Clamp Screw

581-146

105-T30A

www.hitachitoolusa.com

Wrench

© 2005 Hitachi Tool Engineering, Ltd.

11. Inserts

IARPF/ARPF PRECISION FINISHING SERIES

B

PTH08M

ZCFW080-R0.3

•

•

0.3

ZCFW080-R0.5

•

•

0.5

ZCFW080-R1.0

•

•

1.0

ZCFW100-R0.3

•

•

ZCFW100-R0.5

•

ZCFW100-R1.0

ZCFW100-R1.5

PTH08M

ZCFW200-R0.3

•

•

0.3

ZCFW200-R0.5

•

•

0.5

ZCFW200-R1.0

•

•

1.0

0.3

ZCFW200-R1.5

•

•

1.5

•

0.5

ZCFW200-R2.0

•

•

2.0

•

•

1.0

ZCFW200-R3.0

•

•

3.0

•

•

1.5

ZCFW250-R0.3

•

•

0.3

ZCFW100-R2.0

•

•

2.0

ZCFW250-R0.5

•

•

0.5

ZCFW100-R3.0

•

•

3.0

ZCFW250-R1.0

•

•

1.0

ZCFW120-R0.3

•

•

0.3

ZCFW250-R2.0

•

•

2.0

ZCFW120-R0.5

•

•

0.5

ZCFW250-R3.0

•

•

ZCFW120-R1.0

•

•

1.0

R

(mm)

ZCFW120-R1.5

•

•

1.5

ZCFW120-R2.0

•

•

•

•

T

(mm)

ØB

(mm)

9.7

2.1

8

12

14.6

2.7

4.2

10

12

2.0

ZCFW120-R3.0

A

(mm)

3.0

PCS08M

Part No.

PCA12M

PCS08M

METRIC

Part No.

PCA12M

ØB

R

(mm)

ZCFW160-R0.5

•

•

•

•

1.0

ZCFW160-R1.5

•

•

1.5

ZCFW160-R2.0

•

•

ZCFW160-R3.0

•

•

COATING MATERIALS FOR INSERTS

•

0.063

IZCFW080-R3.2

•

20

22.6

6.2

25

A

(in)

T

(in)

ØB

(in)

0.474

0.106

0.375

0.574

0.126

0.500

0.784

0.205

0.750

0.889

0.244

1.000

0.126

•

0.031

•

0.063

•

0.126

•

0.031

•

0.063

IZCFW160-R3.2

3.0

5.2

0.031

IZCFW120-R1.6

2.0

•

IZCFW120-R0.8

16

19.9

0.126

IZCFW080-R1.6

4.2

0.063

•

IZCFW080-R0.8

16.6

•

IZCFW060-R3.2

0.5

ZCFW160-R1.0

IZCFW060-R1.6

0.3

ØB

(mm)

0.031

IZCFW160-R1.6

•

•

IZCFW160-R0.8

•

IZCFW060-R0.8

IZCFW120-R3.2

ZCFW160-R0.3

T

(mm)

3.0

R

(in)

INCH

A

(mm)

•

0.126

Material name

Coating Name

Coating Type

Application

Features

PCA12M

P10

PCA Coating

PVD

General purpose for steel

Uses TiAlN coating; for roughing to finishing

PTH08M

P01-K01

TH Coating

PVD

For high-speed finishing of steel

Uses nano-composite coating; excellent for highspeed cutting and finishing

PCS08M

P01-M01-K01

CS Coating

PVD

For high-speed finishing of steel

Uses nano-composite coating; excellent lubricity

ISO Classification

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

11

12. IABPF/ABPF-S

Ball End Style

Regular Length

IABPF/ABPF PRECISION FINISHING SERIES

L

I

R

I1

B

θ

I

R

lb

I1

ØD

ls

ød1

øD

ød1

øD

ød2

ød2

L

Ød2

A

Ød1

ls

lb

I

R

I1

l

R

ød1

øD

ød1

ød2

L

θ

l1

lb

ls

L

ls

lb

60

BALL NOSE

FINISHING

SEMI-FINISHING

HRC 60

2 FLUTES

R

±0.005

Set-up

±0.010

IABPFS - INCH

Part No.

ØD

Flutes

R

L

l

l1

lb

ls

θ

Ød1

Ød2 Type Insert

IABPF05S08

2

0.313

0.156

3.937

0.156

0.394

0.984

2.953

6.5˚

0.500

0.291

A IZPFG050

IABPF06S08

2

0.375

0.188

3.937

0.187

0.512

0.984

2.953

4.5˚

0.500

0.335

A IZPFG060

IABPF08S08

2

0.500

0.250

4.331

0.250

0.591

1.181

3.150

-

0.500

0.480

B IZPFG080

IABPF10S10

2

0.625

0.313

5.118

0.312

0.748

1.969

3.150

-

0.625

0.602

B IZPFG100

IABPF12S12

2

0.750

0.375

5.512

0.375

0.866

2.362

3.150

-

0.750

0.728

B IZPFG120

IABPF16S16

2

1.000

0.500

5.906

0.500

0.984

2.756

3.150

-

1.000

0.980

B IZPFG160

R

L

l

ABPFS - METRIC

Part No.

l1

lb

ls

θ

5.0

10

22

78

9.5˚

12

100

7.0

13

25

75

5.0˚

110

8.0

15

30

80

-

8.0

130

10.0

19

50

80

10.0

140

12.5

22

60

80

150

15.0

25

70

80

Flutes

ØD

ABPF08S12

2

8

4.0

100

ABPF10S12

2

10

5.0

ABPF12S12

2

12

6.0

ABPF16S20

2

16

ABPF20S25

2

20

ABPF25S32

2

25

12.5

Ød1

Ød2

Type Insert

7.5

A ZPFG080

12

9.5

A ZPFG100

12

11.5

B ZPFG120

2.5˚

20

15.5

A ZPFG160

2.5˚

25

19.5

A ZPFG200

3.0˚

32

24.5

A ZPFG250

Inserts p. 17

Part No.

Clamp Screw

Wrench

IABPF05S08

581-141

104-T8

IABPF06S08

581-142

Part No.

Clamp Screw

Wrench

ABPF08S12

581-141

104-T8

104-T10

ABPF10S12

581-142

104-T10

581-143

105-T20

105-T20

IABPF08S08

105-T20

IABPF10S10

581-144

105-T20

ABPF16S20

581-144

IABPF12S12

581-148

101-T25S

ABPF20S25

581-145

101-T25S

IABPF16S16

12

581-143

ABPF12S12

581-146

105-T30A

ABPF25S32

581-146

105-T30A

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

13. IABPF/ABPF-L

Ball End Style

Long Length

IABPF/ABPF PRECISION FINISHING SERIES

Ød2

ØD

Ød1

l

R

l1

lb

ls

L

60

BALL NOSE

FINISHING

SEMI-FINISHING

HRC 60

2 FLUTES

R

IABPFL - INCH

Part No.

ØD

Flutes

R

L

l

l1

lb

ls

θ

Ød1

Ød2

±0.005

Set-up

±0.010

Type Insert

IABPF05S08L

2

0.313

0.156

5.906

0.156

0.394

1.969

3.937

3.0°

0.500

0.291

A IZPFG050

IABPF06S08L

2

0.375

0.188

5.906

0.187

0.512

1.969

3.937

2.0°

0.500

0.335

A IZPFG060

IABPF08S10L

2

0.500

0.250

6.299

0.250

0.591

2.362

3.937

1.7°

0.625

0.480

A IZPFG080

IABPF10S12L

2

0.625

0.313

6.496

0.312

0.748

2.559

3.937

1.6°

0.750

0.602

A IZPFG100

IABPF12S16L

2

0.750

0.375

7.087

0.375

0.866

3.150

3.937

2.6°

1.000

0.728

A IZPFG120

IABPF16S20L

2

1.000

0.500

7.874

0.500

0.984

3.543

4.331

2.4°

1.250

0.980

A IZPFG160

ABPFL - METRIC

R

L

l

l1

lb

ls

θ

Ød1

8

4.0

130

5.0

10

50

80

3.0°

12

2

10

5.0

150

7.0

13

50

100

5.0°

2

12

6.0

160

8.0

20

60

100

3.0°

ABPF16S20L

2

16

8.0

160

10.0

19

65

95

ABPF20S25L

2

20

10.0

180

12.5

22

80

ABPF25S32L

2

25

12.5

200

15.0

25

90

Part No.

Flutes

ØD

ABPF08S12L

2

ABPF10S16L

ABPF12S16L

Ød2

Type Insert

7.5

A ZPFG080

16

9.5

A ZPFG100

16

10.8

A ZPFG120

2.0°

20

15.5

A ZPFG160

100

2.0°

25

19.5

A ZPFG200

110

3.0°

32

24.5

A ZPFG250

Inserts p. 17

Part No.

Clamp Screw

Wrench

IABPF05S08L

581-141

104-T8

IABPF06S08L

581-142

IABPF08S10L

IABPF10S12L

IABPF12S16L

IABPF16S20L

Clamp Screw

Wrench

ABPF08S12L

581-141

104-T8

104-T10

ABPF10S16L

581-142

104-T10

581-143

105-T20

ABPF12S16L

581-143

105-T20

581-144

105-T20

ABPF16S20L

581-144

105-T20

581-148

101-T25S

ABPF20S25L

581-145

101-T25S

581-146

105-T30A

ABPF25S32L

581-146

105-T30A

phone no. 800.333.1514

Part No.

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

13

14. IABPF/ABPF-W / IABPF-WR

Ball End Style

Carbide Shank

Regular Length

IABPF/ABPF PRECISION FINISHING SERIES

CARBIDE

Ød2

ØD

Ød1

l

R

l1

lb

ls

60

BALL NOSE

FINISHING

SEMI-FINISHING

HRC 60

2 FLUTES

R

IABPFW - INCH

Part No.

Flutes

ØD

R

L

l

l1

lb

ls

Ød1

Ød2

±0.005

Set-up

±0.010

Type Insert

IABPF05S05W

2

0.313

0.156

3.937

0.156

0.709

1.181

2.756

0.313

0.303

B IZPFG050

IABPF06S06W

2

0.375

0.188

3.937

0.187

0.906

1.378

2.559

0.375

0.366

B IZPFG060

IABPF08S08W

2

0.500

0.250

4.331

0.250

1.024

1.772

2.559

0.500

0.472

B IZPFG080

IABPF10S10W

2

0.625

0.313

5.512

0.312

0.748

1.575

3.937

0.625

0.602

B IZPFG100

IABPF12S12W

2

0.750

0.375

6.299

0.375

0.866

2.165

2.559

0.750

0.728

B IZPFG120

IABPF16S16W

2

1.000

0.500

7.087

0.500

0.984

2.559

2.760

1.000

0.980

B IZPFG160

IABPFWR - INCH

Part No.

ØD

R

L

l

l1

lb

ls

Ød1

IABPF05S05WR

Flutes

2

0.313

0.156

5.118

0.156

0.709

2.559

2.559

0.313

0.303

Ød2 Type Insert

B IZPFG050

IABPF06S06WR

2

0.375

0.188

5.512

0.187

0.906

2.953

2.559

0.375

0.366

B IZPFG060

IABPF08S08WR

2

0.500

0.250

5.906

0.250

1.024

3.346

2.559

0.500

0.472

B IZPFG080

ØD

R

L

l

l1

lb

ls

Ød1

ABPFW - METRIC

Part No.

Flutes

Ød2 Type Insert

ABPF08S08W

2

8

4

100

5

18

30

70

8

7.8

B ZPFG080

ABPF10S10W

2

10

5

100

7

23

35

65

10

9.8

B

ABPF12S12W

2

12

6

110

8

26

45

65

12

11.8

ZPFG100

B ZPFG120

Inserts p. 17

Part No.

Wrench

IABPF05S05W

581-141

104-T8

IABPF06S06W

581-142

IABPF08S08W

581-143

IABPF10S10W

IABPF12S12W

IABPF16S16W

14

Clamp Screw

Clamp Screw

Wrench

IABPF05S05WR

581-141

104-T8

104-T10

IABPF06S06WR

581-142

104-T10

105-T20

IABPF08S08WR

581-143

105-T20

581-144

105-T20

ABPF08S08W

581-141

104-T8

581-148

101-T25S

ABPF10S10W

581-142

104-T10

581-146

105-T30A

ABPF12S12W

581-143

105-T20

phone no. 800.333.1514

Part No.

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

15. IABPF/ABPF-WL / ABPF-WE

Ball End Style

Carbide Shank

Long Length / Extra Long Length

IABPF/ABPF PRECISION FINISHING SERIES

CARBIDE

Ød2

Ød1

ØD

l

R

l1

lb

ls

L

60

BALL NOSE

FINISHING

SEMI-FINISHING

HRC 60

2 FLUTES

R

IABPFWL - INCH

Part No.

Flutes

ØD

R

L

l

l1

lb

ls

Ød1

±0.005

Set-up

±0.010

Ød2 Type Insert

IABPF05S05WL

2

0.313

0.156

7.087

0.156

0.394

1.378

5.709

0.313

0.303

B IZPFG050

IABPF06S06WL

2

0.375

0.188

7.087

0.187

0.512

1.378

5.709

0.375

0.366

B IZPFG060

IABPF08S08WL

2

0.500

0.250

7.087

0.250

0.591

1.772

5.315

0.500

0.472

B IZPFG080

IABPF10S10WL

2

0.625

0.313

7.874

0.312

0.787

2.559

5.315

0.625

0.602

B IZPFG100

IABPF12S12WL

2

0.750

0.375

9.843

0.375

0.866

3.150

6.693

0.750

0.728

B IZPFG120

IABPF16S16WL

2

1.000

0.500

9.843

0.500

0.984

3.150

6.693

1.000

0.980

B IZPFG160

ØD

R

L

l

l1

lb

ls

Ød1

ABPFWL - METRIC

Part No.

Flutes

Ød2 Type Insert

ABPF08W08WL

2

8

4

130

5

18

65

65

8

7.8

B ZPFG080

ABPF10S10WL

2

10

5

140

7

23

75

65

10

9.8

B ZPFG100

ABPF12S12WL

2

12

6

150

8

26

85

65

12

11.8

B ZPFG120

Flutes

ØD

R

L

l

l1

lb

ls

Ød1

ABPFWE - METRIC

Part No.

Ød2 Type Insert

ABPF16S16WE

2

16

8.0

200

10.0

19

120

80

16

15.8

B ZPFG160

ABPF20S20WE

2

20

10.0

250

12.5

22

150

100

20

19.8

B ZPFG200

ABPF25S25WE

2

25

12.5

300

15.0

25

190

110

25

24.8

B ZPFG250

Inserts p. 17

Part No.

Clamp Screw

Wrench

IABPF05S05WL

581-141

104-T8

IABPF06S06WL

581-142

IABPF08S08WL

IABPF10S10WL

IABPF12S12WL

IABPF16S16WL

Clamp Screw

Wrench

ABPF08S08WL

581-141

104-T8

104-T10

ABPF10S10WL

581-142

104-T10

581-143

105-T20

ABPF12S12WL

581-143

105-T20

581-144

105-T20

ABPF16S16WE

581-144

105-T20

581-148

101-T25S

ABPF20S20WE

581-145

101-T25S

581-146

105-T30A

ABPF25S25WE

581-146

105-T30A

phone no. 800.333.1514

Part No.

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

15

16. ABPFM

Ball End Style

Modular

IABPF/ABPF PRECISION FINISHING SERIES

L

H

R

M

C

E

øD

ød1

ød2

A

l

B

60

BALL NOSE

SEMI-FINISHING

FINISHING

HRC 60

2 FLUTES

R

Part No.

Flutes

ØD

R

L

ABPFM20

ABPFM25

l Ød1

2

20

10.0

38

12.5

2

25

12.5

38

15.0

±0.005

Set-up

ABPFM - METRIC

±0.010

Ød2

A

B

C

E

M Type Insert

10.5

17.8

5.5

19

10.0

10

M10

15

ZPFG200

12.5

20.8

5.5

22

10.0

10

M12

17

ZPFG250

Inserts p. 17

L

ls

φD

φd2

φd1

l2

M

CARBIDE SHANK - METRIC

Part No.

ØD

ASC20-10.5-170-90

ASC20-10.5-220-120

ASC25-12.5-215-115

ASC25-12.5-265-145

M

10.5

M10

12.5

M12

L

l2

ls

Ød1

170

90

80

18

220

120

100

18

215

115

100

23

265

145

120

23

Ød2

Cutter Body

20

Ø20

25

Ø25

Part No.

581-145

101-T25S

ABPFM25

phone no. 800.333.1514

Wrench

ABPFM20

16

Clamp Screw

581-146

105-T30A

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

17. Inserts

IABPF/ABPF PRECISION FINISHING SERIES

I

PTH08M

R (mm)

A (mm)

T (mm)

ØB (mm)

ZPFG080

•

•

•

4.0

9.7

2.1

8.0

ZPFG100

•

•

•

5.0

12.1

2.7

10.0

ZPFG120

•

•

•

6.0

14.6

3.2

12.0

ZPFG160

•

•

•

15.0

13.5

5.6

12.7

ZPFG200

•

•

•

10.0

20.3

5.2

20.0

ZPFG250

•

•

•

12.5

24.1

6.2

25.0

R (in)

A (in)

T (in)

ØB (in)

PCS08M

METRIC

Part No.

PCA12M

R±0.005

INCH

IZPFG050

•

*

*

0.156

0.381

0.083

0.312

IZPFG060

•

*

*

0.188

0.478

0.106

0.375

IZPFG080

•

*

*

0.250

0.574

0.126

0.500

IZPFG100

•

*

*

0.313

0.653

0.165

0.625

IZPFG120

•

*

*

0.375

0.800

0.205

0.750

IZPFG160

•

*

*

0.500

0.948

0.244

1.000

* Available upon special request

COATING MATERIALS FOR INSERTS

Material name

Coating Name

Coating Type

Application

Features

PCA12M

PCA Coating

General purpose for steel

Uses TiAlN coating; for roughing to finishing

P10

PVD

PTH08M

TH Coating

For high-speed finishing of steel

P01-K01

PVD

Uses nano-composite coating; excellent for highspeed cutting and finishing

PCS08M

CS Coating

For high-speed finishing of steel

Uses nano-composite coating; excellent lubricity

P01-M01-K01

PVD

ISO Classification

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

17

18. IARPF / ARPF

Cutting Conditions

Inch

IARPF/ARPF + IABPF/ABPF

Ø

5/16 or 8mm

No.of flutes

Operation

3/8 or 10mm

2

2

General

High Feed

Finishing

General

High Feed

Finishing

General

N(rpm)

6370

11950

11950

5100

9560

9560

4250

Vc(sfm)

525

984

984

525

984

984

525

Vf(in/min)

100

141

141

80

113

113

67

fz(in/t)

0.008

0.006

0.006

0.008

0.006

0.006

0.008

PCA12M

PTH08M

doc(in)

0.008

0.008

0.004

0.001

0.001

0.004

0.012

woc(in)

0.031

0.016

0.008

0.039

0.020

0.008

0.047

Tool Steel

Alloy Steel

(30-40HRC)

N(rpm)

4780

11150

11150

3830

8920

8920

3190

Vc(sfm)

394

919

919

394

919

919

394

76

132

132

61

106

106

50

fz(in/t)

0.008

0.006

0.006

0.008

0.006

0.006

0.008

doc(in)

0.008

0.008

0.004

0.001

0.001

0.004

0.012

woc(in)

0.031

0.016

0.008

0.039

0.020

0.008

0.047

N(rpm)

4780

11150

11150

3830

8920

8920

3190

Vc(sfm)

394

919

919

394

919

919

394

Carbon Steel

Alloy Steel

(<30HRC)

Vf(in/min)

PCA12M

PTH08M

Tool Steel

Pre-hardened

(40-50HRC)

Vf(in/min)

38

44

44

30

35

35

25

fz(in/t)

0.004

0.002

0.002

0.004

0.002

0.002

0.004

PCA12M

PTH08M

doc(in)

0.008

0.008

0.004

0.001

0.001

0.004

0.012

woc(in)

0.031

0.008

0.008

0.039

0.001

0.008

0.047

Tool Steel

(55-65HRC)

N(rpm)

3190

8760

8760

2550

7010

7010

2130

Vc(sfm)

263

722

722

263

722

722

263

Vf(in/min)

25

35

35

20

28

28

17

fz(in/t)

0.004

0.002

0.002

0.004

0.002

0.002

0.004

doc(in)

0.008

0.008

0.004

0.001

0.001

0.004

0.012

PTH08M

woc(in)

0.031

0.031

0.001

0.039

0.031

0.001

0.047

Cast Iron

N(rpm)

6370

15130

15130

5100

12110

12110

4250

Vc(sfm)

525

1247

1247

525

1247

1247

525

Vf(in/min)

151

239

239

121

191

191

100

fz(in/t)

0.012

0.008

0.008

0.012

0.008

0.008

0.012

doc(in)

0.008

0.008

0.004

0.001

0.008

0.004

0.012

woc(in)

0.031

0.016

0.008

0.039

0.016

0.008

0.047

PCA12M

PTH08M

18

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

19. IARPF / ARPF

Cutting Conditions

Inch

(continued)

IARPF/ARPF + IABPF/ABPF

1/2 or 12mm

5/8 or 16mm

2

3/4 or 20mm

2

1 or 25mm

2

2

High Feed

Finishing

General

High Feed

Finishing

General

High Feed

Finishing

General

High Feed

Finishing

7970

7970

2550

4780

4780

2550

4780

4780

2040

3830

3830

984

984

525

984

984

525

984

984

525

984

984

95

157

50

76

76

50

76

76

40

61

61

0.006

0.001

0.001

0.008

0.008

0.001

0.008

0.008

0.001

0.008

0.008

0.012

0.004

0.031

0.031

0.008

0.039

0.039

0.008

0.049

0.049

0.008

0.024

0.008

0.063

0.063

0.008

0.079

0.079

0.008

0.098

0.049

0.008

7440

7440

1920

4460

4460

1920

4460

4460

1530

3570

3570

919

919

394

919

919

394

919

919

394

919

919

88

88

38

71

71

38

71

71

30

56

56

0.006

0.006

0.001

0.008

0.008

0.001

0.008

0.008

0.001

0.008

0.008

0.012

0.004

0.031

0.031

0.008

0.039

0.039

0.008

0.049

0.049

0.008

0.024

0.008

0.063

0.063

0.008

0.079

0.079

0.008

0.098

0.098

0.008

7440

7440

1600

4460

4460

1600

4460

4460

1280

3570

3570

919

919

328

919

919

328

919

919

328

919

919

30

30

15

21

21

15

21

21

12

17

17

0.002

0.002

0.005

0.002

0.002

0.005

0.002

0.002

0.005

0.002

0.002

0.012

0.004

0.031

0.031

0.008

0.039

0.039

0.008

0.049

0.049

0.008

0.012

0.008

0.063

0.031

0.008

0.079

0.039

0.008

0.098

0.049

0.008

5840

5840

1280

3510

3510

1280

3510

3510

1020

2810

2810

722

722

263

722

722

263

722

722

263

722

722

23

23

12

17

17

12

17

17

10

13

13

0.002

0.002

0.005

0.002

0.002

0.005

0.002

0.002

0.005

0.002

0.002

0.012

0.004

0.031

0.031

0.008

0.039

0.039

0.008

0.049

0.049

0.008

0.035

0.012

0.063

0.031

0.008

0.079

0.039

0.008

0.098

0.049

0.008

10090

10090

2550

6060

6060

2550

6060

6060

2040

4850

4850

1247

1247

525

1247

1247

525

1247

1247

525

1247

1247

159

159

71

143

143

71

143

143

56

115

115

0.008

0.008

0.014

0.012

0.012

0.014

0.012

0.012

0.014

0.012

0.012

0.012

0.004

0.031

0.031

0.008

0.039

0.039

0.008

0.049

0.049

0.008

0.024

0.008

0.063

0.063

0.008

0.079

0.079

0.008

0.098

0.098

0.008

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

19

20. IARPF / ARPF

Cutting Conditions

Metric

IARPF/ARPF + IABPF/ABPF

Øφ

5/16 or 8mm

No.of flutes

Operation

Carbon Steel

Alloy Steel

(<30HRC)

N(rpm)

3/8 or 10mm

2

2

General

High Feed

Finishing

General

High Feed

Finishing

General

6370

11950

11950

5100

9560

9560

4250

Vc(m/min)

160

300

300

160

300

300

160

Vf(mm/min)

2550

3590

3590

2040

2870

2870

1700

fz(mm/t)

0.2

0.15

0.15

0.2

0.15

0.15

0.2

PCA12M

PTH08M

doc(mm)

0.2

0.2

0.1

0.25

0.25

0.1

0.3

woc(mm)

0.8

0.4

0.2

1

0.5

0.2

1.2

Tool Steel

Alloy Steel

(30-40HRC)

N(rpm)

4780

11150

11150

3830

8920

8920

3190

Vc(m/min)

120

280

280

120

280

280

120

Vf(mm/min)

1920

3350

3350

1540

2680

2680

1280

fz(mm/t)

0.2

0.15

0.15

0.2

0.15

0.15

0.2

PCA12M

PTH08M

doc(mm)

0.2

0.2

0.1

0.25

0.25

0.1

0.3

Tool Steel

Pre-hardened

(40-50HRC)

N(rpm)

woc(mm)

0.8

0.4

0.2

1

0.5

0.2

1.2

4780

11150

11150

3830

8920

8920

3190

Vc(m/min)

120

280

280

120

280

280

120

Vf(mm/min)

960

1120

1120

770

900

900

640

fz(mm/t)

0.1

0.05

0.05

0.1

0.05

0.05

0.1

PCA12M

PTH08M

doc(mm)

0.2

0.2

0.1

0.25

0.25

0.1

0.3

Tool Steel

(55-65HRC)

N(rpm)

woc(mm)

0.8

0.2

0.2

1

0.25

0.2

1.2

3190

8760

8760

2550

7010

7010

2130

Vc(m/min)

80

220

220

80

220

220

80

Vf(mm/min)

640

880

880

510

710

710

430

fz(mm/t)

0.1

0.05

0.05

0.1

0.05

0.05

0.1

doc(mm)

0.2

0.2

0.1

0.25

0.25

0.1

0.3

PTH08M

woc(mm)

0.8

0.8

0.25

1

0.8

0.25

1.2

Cast Iron

N(rpm)

6370

15130

15130

5100

12110

12110

4250

Vc(m/min)

20

380

380

160

380

380

160

3830

6060

6060

3060

4850

4850

2550

fz(mm/t)

PCA12M

PTH08M

160

Vf(mm/min)

0.3

0.2

0.2

0.3

0.2

0.2

0.3

doc(mm)

0.2

0.2

0.1

0.25

0.2

0.1

0.3

woc(mm)

0.8

0.4

0.2

1

0.4

0.2

1.2

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

21. IARPF / ARPF

Cutting Conditions

Metric

(continued)

IARPF/ARPF + IABPF/ABPF

1/2 or 12mm

5/8 or 16mm

2

3/4 or 20mm

2

1 or 25mm

2

2

High Feed

Finishing

General

High Feed

Finishing

General

High Feed

Finishing

General

High Feed

Finishing

7970

7970

2550

4780

4780

2550

4780

4780

2040

3830

3830

300

300

160

300

300

160

300

300

160

300

300

2400

3990

1280

1920

1920

1280

1920

1920

1020

1540

1540

0.15

0.25

0.25

0.2

0.2

0.25

0.2

0.2

0.25

0.2

0.2

0.3

0.1

0.8

0.8

0.2

1

1

0.2

1.25

1.25

0.2

0.6

0.2

1.6

1.6

0.2

2

2

0.2

2.5

1.25

0.2

7440

7440

1920

4460

4460

1920

4460

4460

1530

3570

3570

280

280

120

280

280

120

280

280

120

280

280

2240

2240

960

1790

1790

960

1790

1790

770

1430

1430

0.15

0.15

0.25

0.2

0.2

0.25

0.2

0.2

0.25

0.2

0.2

0.3

0.1

0.8

0.8

0.2

1

1

0.2

1.25

1.25

0.2

0.6

0.2

1.6

1.6

0.2

2

2

0.2

2.5

2.5

0.2

7440

7440

1600

4460

4460

1600

4460

4460

1280

3570

3570

280

280

100

280

280

100

280

280

100

280

280

750

750

390

540

540

390

540

540

310

430

430

0.05

0.05

0.12

0.06

0.06

0.12

0.06

0.06

0.12

0.06

0.06

0.3

0.1

0.8

0.8

0.2

1

1

0.2

1.25

1.25

0.2

0.3

0.2

1.6

0.8

0.2

2

1

0.2

2.5

1.25

0.2

5840

5840

1280

3510

3510

1280

3510

3510

1020

2810

2810

220

220

80

220

220

80

220

220

80

220

220

590

590

310

430

430

310

430

430

250

340

340

0.05

0.05

0.12

0.06

0.06

0.12

0.06

0.06

0.12

0.06

0.06

0.3

0.1

0.8

0.8

0.2

1

1

0.2

1.25

1.25

0.2

0.9

0.3

1.6

0.8

0.2

2

1

0.2

2.5

1.25

0.2

10090

10090

2550

6060

6060

2550

6060

6060

2040

4850

4850

380

380

160

380

380

160

380

380

160

380

380

4040

4040

1790

3640

3640

1790

3640

3640

1430

2910

2910

0.2

0.2

0.35

0.3

0.3

0.35

0.3

0.3

0.35

0.3

0.3

0.3

0.1

0.8

0.8

0.2

1

1

0.2

1.25

1.25

0.2

0.6

0.2

1.6

1.6

0.2

2

2

0.2

2.5

2.5

0.2

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

21

22. IABPF / ABPF

Cutting Conditions

Inch

IARPF/ARPF + IABPF/ABPF

φØ

5/16 or 8mm

No.of flutes

Operation

Carbon Steel

Alloy Steel

(<30HRC)

3/8 or 10mm

2

2

General

High Feed

Finishing

General

High Feed

Finishing

General

N(rpm)

6370

12350

12350

5100

9240

11150

4250

Vc(sfm)

525

1017

1017

525

951

1148

525

100

389

195

80

291

176

67

fz(in/t)

0.008

0.016

0.008

0.008

0.016

0.008

0.008

PCA12M

PTH08M

doc(in)

0.008

0.004

0.004

0.001

0.006

0.004

0.012

woc(in)

0.031

0.031

0.001

0.039

0.031

0.001

0.047

Tool Steel

Alloy Steel

(30-40HRC)

N(rpm)

4780

10750

10750

3830

7650

9560

3190

Vc(sfm)

394

886

886

394

787

984

394

76

339

169

61

241

151

50

fz(in/t)

0.008

0.016

0.008

0.008

0.016

0.008

0.008

doc(in)

0.008

0.004

0.004

0.001

0.006

0.004

0.012

woc(in)

0.031

0.031

0.001

0.039

0.031

0.001

0.047

N(rpm)

3990

9160

9160

3190

6690

8290

2660

Vc(sfm)

328

755

755

328

689

853

328

PCA12M

PTH08M

Tool Steel

Pre-hardened

(40-50HRC)

Vf(in/min)

Vf(in/min)

Vf(in/min)

32

145

145

25

106

131

21

fz(in/t)

0.004

0.008

0.008

0.004

0.008

0.008

0.004

PCA12M

PTH08M

doc(in)

0.008

0.004

0.004

0.001

0.006

0.004

0.012

woc(in)

0.031

0.031

0.001

0.039

0.031

0.001

0.047

Tool Steel

(55-65HRC)

N(rpm)

7170

9160

9160

5740

7010

7650

4780

Vc(sfm)

591

755

755

591

722

787

591

57

145

145

45

111

121

38

fz(in/t)

0.004

0.008

0.008

0.004

0.008

0.008

0.004

doc(in)

0.004

0.008

0.008

0.001

0.006

0.004

0.012

PTH08M

woc(in)

0.031

0.031

0.001

0.039

0.031

0.001

0.047

Cast Iron

N(rpm)

6370

12350

12350

5100

9240

11150

4250

Vc(sfm)

525

1017

1017

525

951

1148

525

Vf(in/min)

Vf(in/min)

PCA12M

PTH08M

22

151

584

195

121

437

263

100

fz(in/t)

0.012

0.024

0.008

0.012

0.024

0.012

0.012

doc(in)

0.008

0.004

0.004

0.001

0.006

0.004

0.012

woc(in)

0.031

0.031

0.001

0.039

0.031

0.001

0.047

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

23. IABPF / ABPF

Cutting Conditions

Inch

(continued)

IARPF/ARPF + IABPF/ABPF

1/2 or 12mm

5/8 or 16mm

2

3/4 or 20mm

2

1 or 25mm

2

2

High Feed

Finishing

General

High Feed

Finishing

General

High Feed

Finishing

General

High Feed

Finishing

7170

10090

2550

3350

7970

2550

3350

9080

2040

2680

8030

886

1247

525

689

1640

525

689

1870

525

689

2067

226

159

50

132

189

50

132

286

40

106

316

0.016

0.008

0.001

0.020

0.012

0.001

0.020

0.016

0.001

0.020

0.020

0.008

0.004

0.031

0.024

0.004

0.039

0.028

0.004

0.049

0.035

0.004

0.035

0.012

0.063

0.043

0.014

0.079

0.059

0.016

0.098

0.071

0.020

6110

8760

1920

2390

6060

1920

2550

6690

1530

2040

5990

755

1083

394

492

1247

394

525

1378

394

525

1542

193

138

38

94

143

38

100

211

30

80

236

0.016

0.008

0.001

0.020

0.012

0.001

0.020

0.016

0.001

0.020

0.020

0.008

0.004

0.031

0.024

0.004

0.039

0.028

0.004

0.049

0.035

0.004

0.035

0.012

0.063

0.043

0.012

0.079

0.059

0.016

0.098

0.071

0.020

5310

7700

1600

2390

5580

1600

2390

6370

1280

1920

5740

656

951

328

492

1148

328

492

1312

328

492

1476

84

121

15

45

132

15

45

201

12

37

226

0.008

0.008

0.005

0.009

0.012

0.005

0.009

0.016

0.005

0.009

0.020

0.008

0.004

0.031

0.024

0.004

0.039

0.028

0.004

0.049

0.035

0.004

0.035

0.012

0.063

0.043

0.012

0.079

0.059

0.016

0.098

0.071

0.020

5580

6640

2870

3190

4460

2870

3190

5100

2300

2550

4590

689

820

591

656

919

591

656

1050

591

656

1181

88

105

27

61

106

27

61

161

22

48

181

0.008

0.008

0.005

0.009

0.012

0.005

0.009

0.016

0.005

0.009

0.020

0.008

0.004

0.031

0.024

0.004

0.039

0.028

0.004

0.049

0.035

0.004

0.035

0.012

0.063

0.043

0.012

0.079

0.059

0.016

0.098

0.071

0.020

7170

10090

2550

3350

7970

2550

3350

9080

2040

2680

8030

886

1247

525

689

1640

525

689

1870

525

689

2067

339

239

71

185

189

71

185

286

56

148

316

0.024

0.012

0.014

0.028

0.012

0.014

0.028

0.016

0.014

0.028

0.020

0.008

0.004

0.031

0.024

0.004

0.039

0.028

0.004

0.049

0.035

0.004

0.035

0.012

0.063

0.043

0.012

0.079

0.059

0.016

0.098

0.071

0.020

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

23

24. IABPF / ABPF

Cutting Conditions

Metric

IARPF/ARPF + IABPF/ABPF

Ø

5/16 or 8mm

No.of flutes

Operation

Carbon Steel

Alloy Steel

(<30HRC)

PCA12M

PTH08M

PCS08M

Tool Steel

Alloy Steel

(30-40HRC)

PCA12M

PTH08M

PCS08M

Tool Steel

Pre-hardened

(40-50HRC)

N(rpm)

3/8 or 10mm

2

2

General

High Feed

Finishing

General

High Feed

Finishing

General

6370

12350

12350

5100

9240

11150

4250

Vc(m/min)

160

310

310

160

290

350

160

Vf(mm/min)

2550

9880

4940

2040

7400

4460

1700

fz(mm/t)

0.2

0.4

0.2

0.2

0.4

0.2

0.2

doc(mm)

0.2

0.1

0.1

0.25

0.15

0.1

0.3

woc(mm)

0.8

0.8

0.25

1

0.8

0.25

1.2

N(rpm)

4780

10750

10750

3830

7650

9560

3190

Vc(m/min)

120

270

270

120

240

300

120

Vf(mm/min)

1920

8600

4300

1540

6120

3830

1280

fz(mm/t)

0.2

0.4

0.2

0.2

0.4

0.2

0.2

doc(mm)

0.2

0.1

0.1

0.25

0.15

0.1

0.3

woc(mm)

0.8

0.8

0.25

1

0.8

0.25

1.2

3990

9160

9160

3190

6690

8290

2660

N(rpm)

100

230

230

100

210

260

100

Vf(mm/min)

800

3670

3670

640

2680

3320

540

fz(mm/t)

PTH08M

PCS08M

Vc(m/min)

0.1

0.2

0.2

0.1

0.2

0.2

0.1

doc(mm)

0.2

0.1

0.1

0.25

0.15

0.1

0.3

0.8

0.8

0.25

1

0.8

0.25

1.2

7170

9160

9160

5740

7010

7650

4780

Vc(m/min)

180

230

230

180

220

240

180

Vf(mm/min)

Tool Steel

(55-65HRC)

woc(mm)

N(rpm)

PTH08M

PCS08M

Cast Iron

1440

3670

3670

1150

2810

3060

960

fz(mm/t)

0.1

0.2

0.2

0.1

0.2

0.2

0.1

doc(mm)

0.1

0.2

0.2

0.25

0.15

0.1

0.3

woc(mm)

0.8

0.8

0.25

1

0.8

0.25

1.2

6370

12350

12350

5100

9240

11150

4250

N(rpm)

Vc(m/min)

24

310

310

160

290

350

160

3830

14820

4940

3060

11090

6690

2550

fz(mm/t)

PTH08M

PCS08M

160

Vf(mm/min)

0.3

0.6

0.2

0.3

0.6

0.3

0.3

doc(mm)

0.2

0.1

0.1

0.25

0.15

0.1

0.3

woc(mm)

0.8

0.8

0.25

1

0.8

0.25

1.2

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

25. IABPF / ABPF

Cutting Conditions

Metric

(continued)

IARPF/ARPF + IABPF/ABPF

1/2 or 12mm

5/8 or 16mm

2

3/4 or 20mm

2

1 or 25mm

2

2

High Feed

Finishing

General

High Feed

Finishing

General

High Feed

Finishing

General

High Feed

Finishing

7170

10090

2550

3350

7970

2550

3350

9080

2040

2680

8030

270

380

160

210

500

160

210

570

160

210

630

5740

4040

1280

3350

4790

1280

3350

7270

1020

2680

8030

0.4

0.2

0.25

0.5

0.3

0.25

0.5

0.4

0.25

0.5

0.5

0.2

0.1

0.8

0.6

0.1

1

0.7

0.1

1.25

0.9

0.1

0.9

0.3

1.6

1.1

0.35

2

1.5

0.4

2.5

1.8

0.5

6110

8760

1920

2390

6060

1920

2550

6690

1530

2040

5990

230

330

120

150

380

120

160

420

120

160

470

4890

3510

960

2390

3640

960

2550

5360

770

2040

5990

0.4

0.2

0.25

0.5

0.3

0.25

0.5

0.4

0.25

0.5

0.5

0.2

0.1

0.8

0.6

0.1

1

0.7

0.1

1.25

0.9

0.1

0.9

0.3

1.6

1.1

0.3

2

1.5

0.4

2.5

1.8

0.5

5310

7700

1600

2390

5580

1600

2390

6370

1280

1920

5740

200

290

100

150

350

100

150

400

100

150

450

2130

3080

390

1150

3350

390

1150

5100

310

930

5740

0.2

0.2

0.12

0.24

0.3

0.12

0.24

0.4

0.12

0.24

0.5

0.2

0.1

0.8

0.6

0.1

1

0.7

0.1

1.25

0.9

0.1

0.9

0.3

1.6

1.1

0.3

2

1.5

0.4

2.5

1.8

0.5

5580

6640

2870

3190

4460

2870

3190

5100

2300

2550

4590

210

250

180

200

280

180

200

320

180

200

360

2240

2660

690

1540

2680

690

1540

4080

560

1230

4590

0.2

0.2

0.12

0.24

0.3

0.12

0.24

0.4

0.12

0.24

0.5

0.2

0.1

0.8

0.6

0.1

1

0.7

0.1

1.25

0.9

0.1

0.9

0.3

1.6

1.1

0.3

2

1.5

0.4

2.5

1.8

0.5

7170

10090

2550

3350

7970

2550

3350

9080

2040

2680

8030

270

380

160

210

500

160

210

570

160

210

630

8610

6060

1790

4690

4790

1790

4690

7270

1430

3760

8030

0.6

0.3

0.35

0.7

0.3

0.35

0.7

0.4

0.35

0.7

0.5

0.2

0.1

0.8

0.6

0.1

1

0.7

0.1

1.25

0.9

0.1

0.9

0.3

1.6

1.1

0.3

2

1.5

0.4

2.5

1.8

0.5

phone no. 800.333.1514

www.hitachitoolusa.com

© 2005 Hitachi Tool Engineering, Ltd.

25

26. IARPF/ARPF + IABPF/ABPF

Soft, Low-carbon steels

Low carbon and purely ferritic mild steels

Free cutting steels

(not including stainless steels)

Machine steels and carbon steels

Low to medium carbon content (0.5%C)

High carbon and low-alloy steels

Medium-hard quenching and tempering steels

High carbon steels (0.5%C)

Ferritic and martensitic stainless steels

Normal tool steels

Harder quenching and tempering steels

Martensitic stainless steels

Difficult to machine tool steels

High-alloy, high-hardness steels

Martensitic stainless steels

Difficult to machine high-strength, high-hardness steels

Easy-cutting stainless steels

Free-cutting stainless steels

Calcium-treated stainless steels

26

phone no. 800.333.1514

Material Cross Reference

Steels and Iron

AISI

1015

1022

1025

1213

12L13

12L14

1015

1043

1055

1042

1045

1042

1064

1070

1080

1095

9254

1335

5120

4130

4135

4140

5140

8620

403

410S

410

P4

405

430

434

416

430F

409

430Ti

420

P20+1

4340

431

440B

P3

P20

H13

A2

D2

M2

M7

446

422

429

440C

A12875

304

303

304L

305

302

301

JIS

S15C

SMnC420

S25C

SUM22

SUM22L

S15CK

S45C

S55C

S45C

S45C

S58C

SUP4

SMn438(H)

SCM420

SCM432

SCM440

SCr440

SNCM220(H)

SUS403

SUS410S

SUS410

SUS405

SUS430

SUS434

SUS430F

SUH409

SUS420J1

SNCM447

SUS431

SUS440B

SKD1

SKD61

SKD12

SKH9

SUH446

SUS440C

SCMnH1

SUS304

SUS303

SUS304L

SUS305

SUS302

SUS301

www.hitachitoolusa.com

German

1.040

1.113

1.116

1.072

1.072

1.074

1.114

1.050

1.054

1.119

1.173

1.119

1.122

1.123

1.125

1.127

1.090

1.117

1.084

1.722

1.233

1.723

1.705

1.652

1.400

1.400

1.401

1.234

1.472

1.402

1.411

1.401

1.410

1.451

1.451

1.402

1.231

1.658

1.406

1.411

1.208

1.231

1.234

1.236

1.238

1.334

1.335

1.475

1.494

1.413

1.340

1.430

1.431

1.431

1.431

1.431

DIN

C15

GS-20Mn5

Ck25

9SMn28

9SMnPb28

9SMnPb36

Ck15

C45

C55

Ck45

C45W

Ck45

Ck60

Ck67

Ck75

Ck101

55Si7

36Mn5

St52-3

25CrMo4

35CrMo4

42CrMo4

42Cr41

21NiCrMo2

X6Cr13

X7Cr14

G-X10Cr13

X6CrMo4

X6CrAl13

X6Cr17

X6CrMo17

X12CrS13

X12CrMoS17

X5CrTi12

X6CrTi17

X42Cr13

40CrMnMoS86

34CrNiMo6

X20CrNi172

X90CrMoV18

X210Cr12

40CrMnMo7

X40CrMoV51

X100CrMoV51

X155CrMoV121

S6/5/2

S2/9/2

X18CrN28

X20CrMoWV121

X10CrNi15

X105CrMo17

G-X120mN12

X5CrNi1810

X10CrNiS189

X2CrNi1810

X8CrNi1812

X12CrNi189

X12CrNi177

© 2005 Hitachi Tool Engineering, Ltd.

27. Material Cross Reference

Steels and Iron

IARPF/ARPF + IABPF/ABPF

Moderately difficult to machine stainless steels

Austenitic and duplex stainless steels

Difficult to machine stainless steels

Austenitic and duplex stainless steels

Extremely difficult to machine stainless steels

Austenitic and duplex stainless steels

Moderately hard cast iron

Gray iron

Low-alloy cast iron

Malleable cast iron, SG iron

Moderately difficult to machine alloy cast iron

Moderately difficult to machine malleable iron, SG iron

Difficult to machine high-alloy cast iron

Difficult to machine malleable cast iron, SG iron

phone no. 800.333.1514

AISI

316

316Ti

316

316L

316Ti

304LN

202

660

330

309

310

316LN

60/40/18

60/40/18

A220-40010

A220-50005

A48-30B

A48-40B

A436 Type 2

65/45/12

80/55/06

A220-50005

A220-70003

A48-45B

100/70/03

A43D2

A220-70003

A220-80002

A220-90001

A48-50B

A48-60B

A220-90001

www.hitachitoolusa.com

JIS

SUS316

SUS316

SUS316L

SUS304LN

SUS202

SUH330

SUS316LN

FCD400

FCMP440/490

FCMP540

FC200

FC250

FCD500

FCD600

FCMP540

FCMP590

FC300

FCD700

FCMP590

FCMP690

FC35

FC40

FCMP690

German

1.444

1.457

1.440

1.440

1.457

1.431

1.437

1.498

1.486

1.484

1.441

0.704

0.704

0.815

0.816

0.602

0.603

0.666

0.705

0.706

0.816

0.817

0.603

0.707

0.766

0.817

0.817

0.817

0.604

0.604

0.817

DIN

X5CrNiMo17133

X8CrNiMoTi17122

X5CrNiMo17122

X2CrNiMo17132

X6CrNiMoTi17122

X2CrNiN1810

X3CrMnNiN1887

X5NiCrTi2515

X12NiCrSi16

X15CrNi2313

X15CrNiSi2520

X2CrNiMoN17132

GGG-40

GGG-40.3

GTS-45-06

GTS-55-04

GG-20

GG-25

GGL-NiCr202

GGG-50

GGG-60

GTS-55-04

GTS-65-02

GG-30

GGG-70

GGG-NiCr202

GTS-65-02

GTS-70-02

GTS-70-02

GG-35

GG-40

GTS-70-02

© 2005 Hitachi Tool Engineering, Ltd.

27

28. DISTRIBUTED BY

Hitachi Metals America, LTD.

Material Trading Division, Cutting Tools Group

41800 W. Eleven Mile Road, Suite 100

Novi, MI 48375

© 2005 Hitachi Tool Engineering, Ltd.

Tel. 800.333.1514

Fax 248.465.6020

email info@hitachitoolusa.com

www.hitachitoolusa.com

1st Edition

Printed in USA