More Related Content

More from Trigonenterprisespvtltd

More from Trigonenterprisespvtltd (18)

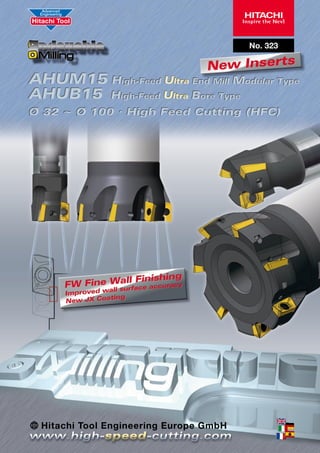

Ahub face mill cutter.

- 2. Indexable Milling Tools

AHU15 | High Feed Ultra

HIGH-FEED ULTRA END MILL

HIGH-FEED ULTRA END MILL

1. Main cutting forces are reduced by the unique high rake

geometry

1. El esfuerzo de corte se reduce gracias a una exclusiva

geometría altamente positiva.

2. Ramp milling is possible

2. Capaz de mecanizar en rampa

3. 30% increased rigidity over conventional indexable endmills due to the utilization of a special steel material and

chip pocket geometry

3. 30% más de rigidez que herramientas de plaquita

4. Through tool coolant is available

5. Dispone de canal de refrigeración interior.

5. New substrate and coating technology has been adopted

which allows longer tool-life and the ability to use higher

cutting speeds

HIGH-FEED ULTRA END MILL

4. convencionales gracias a la utilización de un acero especial y a la geometría del canal de evacuación de viruta

6. La combinación de substratos y recubrimientos de ultima

tecnología permite una mayor vida de herramienta y la

capacidad de usar velocidades de corte mayores

HIGH-FEED ULTRA END MILL

1. Durch die einzigartige hochpositive Schneidengeometrie

des AHU High Feed Ultra wird der Schnittdruck erheblich

reduziert

1. L’angle de dépouille très prononcé permet à lui seul de

réduire la majeure partie des efforts de coupe.

2. Auch Fräsoperationen über Rampe sind möglich

3. Rigidité accrue de 30% par rapport aux fraises à plaquettes rapportées due à l’utilisation d’un acier spécial et à la

forme des poches à copeaux.

3. Die Verwendung eines speziellen Stahls und einer neu

entwickelten Spankammer-Geometrie erhöhte die Steifigkeit des AHU High Feed Ultra gegenüber konventionellen

WSP-Haltern um 30%

4. Zusätzlich verfügt der AHU High Feed Ultra über innen

liegende Kühlkanäle

5. Durch das neue Substrat der Wendeschneidplatten in

Verbindung mit einer neuen Beschichtungstechnologie

ermöglicht der AHU High Feed Ultra wesentlich höhere

Schnittgeschwindigkeiten bei gleichzeitig längeren

Standzeiten

2. L’usinage de rampes est possible (ramping).

4. Deux versions de corps sont disponibles : avec ou sans

arrosage au centre.

5. Nous avons développés une nouvelle nuance et une nouvelle technologie de revêtement générant une durée de vie

supérieure et une augmentation significative des vitesses

de coupe.

HIGH-FEED ULTRA END MILL

1. Maggiore stabilità e minori forze di taglio grazie alla nuova

geometria positiva della spoglia.

2. La fresatura in rampa è possibile

3. 30 % maggiore rigidità a confronto con frese convenzionali grazie alla particolare geometria del collo rompitruciolo e una microfusione di acciaio del corpo fresa.

4. Refrigerante attraverso il corpo fresa disponibile

5. La combinazione dello sviluppo di una micrograna

6. particolare con l´ultimo sviluppo di rivestimenti rende

possibile un grande allungamento di vita dell’utensile e

l´utilizzo di velocità di taglio più elevate.

2

© 2009 Hitachi Tool Engineering Europe GmbH

Errors and alterations excepted · Änderungen und Irrtum vorbehalten

- 3. Indexable Milling Tools

AHUM15 | High Feed Ultra Modular Type

Q max

Jet

High Efficient

Air Hole

No. of

Teeth

HRC

Roughing

Finishing

50

3~4

M

l

H

Ød1 Ød2

ØD

H

M

C

E

A

Ød2

Ød1

ØD

B

H

l

A

Tolerance

Torque on screw

B

Modular Type

ID Code Item Code

AHUM-1532R-3-M16

FH066

AHUM-1540R-4-M16

FH067

Flutes

3

4

ØD

32

40

H

40

45

ØD 0/-0.2

3 Nm

Ød1

M

Ød2

A

B

C

E

l

17

16

28.8

6

23

12

22

14

Inserts

JDMT1505..R.. JX10..

AHUB15 | High Feed Ultra Bore Type

Q max

Jet

High Efficient

Air Hole

No. of

Teeth

HRC

Roughing

Finishing

50

4~8

Ød2

Ød

A

B

C

Ød2

Ød

H

A

H

B

l

M

C

E

C

H

Ød2

Ød1

ØD

ØD

l

A

Ød1

B

ØD

Tolerance

Torque on screw

Face Mill

ID Code

FH060

FH061

FH062

FH063

FH064

FH065

Item Code

Flutes ØD

AHUB-1540RM-4-16

40

4

AHUB-1550RM-5-22

50

5

AHUB-1550RM-5-27

AHUB-1563RM-6-27

63

6

AHUB-1580RM-7-27

80

7

AHUB-15100RM-8-32

100

8

H

45

50

63

Ød

16

22

Ød1

11.5

17

M

8*

10

27

20

12

32

26

16

Ød2

35

40

45

60

70

A

8.4

10.4

B

5.6

6.3

C

18

20

12.4

7

22

14.4

8

ØD 0/-0.2

3 Nm

I

25.5

14

Inserts

JDMT1505..R.. JX10..

* Special Screw

© 2009 Hitachi Tool Engineering Europe GmbH

Errors and alterations excepted · Änderungen und Irrtum vorbehalten

3

- 4. Indexable Milling Tools

A

INSERTS

B

15°

A

R

B

T

15°

T

R

ID Code

WF182

WF183

WF184

WF185

WF186

WF187

Item Code

JDMT150504R-FW JX1045

JDMT150508R-FW JX1020

JDMT150508R-FW JX1045

JDMT150508R-FW JX1060

JDMT150520R JX1045

JDMT150530R JX1045

NEW

P01

P10

P20

P30

P40

Grade

JX1045

JX1020

JX1045

JX1060

JX1045

JX1045

A

9.12

5

M01

Grade Overview

ISO

M10

M20

M30

M40

K01

K10

K20

JX1060

N40

S10

S20

K40

JX1045

JX1060

S01

K30

JX1020

JX1045

N30

0.8

JX1020 – 1060 PVD Coating / Dry Cutting

JX1020

N20

R

0.4

2.0

3.0

JX1045

N10

T

16

JX1020

N01

B

S30

JX1060

S40

H01

H10

JX1020

H20

H30

H40

JX1020

JX1060

Parts

Clamp Screw

Wrench

ID-Code

Item-Code

ID-Code

Item-Code

ET038

412-141

ET049

105-T15

AHU-M

AHU-B

Special screw

AHUB-1540RM-4-16

4

ID-Code

Item-Code

ET050

K06-676

© 2009 Hitachi Tool Engineering Europe GmbH

Errors and alterations excepted · Änderungen und Irrtum vorbehalten

- 5. Indexable Milling Tools

AHU15 | High Feed Ultra – improved cutting surface

Fine Wall type JDMT……R-FW

Fine Wall type JDMT……R-FW

Conventional (JDMT……R)

Conventional (JDMT……R)

= outermost point

= outermost point

= outermost point

= outermost point

aeae

aeae

(mm)

apap (mm)

(mm)

apap (mm)

Ramp Angle

Ramping

Hole Ø

Helical Milling

Cutting edge Ø (mm)

Ramping Angle

Helical Milling / Hole Dia. (mm)

Ø 32

4°

47~60

40

3°

64~76

50

2°

83~96

63

1.5°

122~109

80

1°

156~143

100

1°

196~183

AHU15 | Recommended Cutting Conditions

1. Please choose the best conditions from the table

2. To reduce tool breakage index the inserts earlier than the maximum edge life

3. Chips can become hot and can cause burns or damage to eyes. Please ensure

machine guards are used, and safety specs and gloves worn at all times when

carrying out work near to the tool or workpiece

4. Please ensure caution when using neat cutting oil due to the risk of fire

1. Bitte wählen Sie aus der Tabelle die für Ihre Anwendung am besten geeigneten

Bedingungen

2. Um die Gefahr des Werkzeugbruchs zu reduzieren, sollten die

Wendeschneidplatten gewechselt werden, bevor die maximale Standzeit der

Schneide erreicht ist

3. Die während der Bearbeitung entstehenden Späne können sehr heiß werden

und zu Verbrennungen oder Verletzungen von Haut und Augen führen.

Bitte stellen Sie sicher, dass während der Bearbeitung die Maschinentüren

geschlossen sind. Bei Arbeiten in der Nähe oder direkt am Werkzeug oder

Werkstück, sollten immer eine Schutzbrille und Handschuhe getragen werden

4. Erhöhte Vorsicht ist geboten beim Einsatz von purem Schneidöl,

da es sich während der Bearbeitung entzünden kann

1. Seleccionar las condiciones de la tabla de indicada

2. Para reducir el riesgo de rotura de la herramienta hay cambiar la plaquita antes

de agotar la vida máxima del filo

3. Las virutas pueden saltar candentes y pueden causar quemaduras o daño en

los ojos.

4. Por favor, asegúrese de cerrar las protecciones de la máquina y de que son

utilizados gafas y guantes en todo momento al realizar trabajos cerca de la

herramienta o la pieza.

5. Por favor, tome precaución al utilizar aceite de corte debido al riesgo de

ignición.

1. Veuillez choisir les conditions de coupes les mieux adaptées grâce au tableau.

2. Pour réduire les risques de rupture de l’outil, changez l’insert avant d’avoir

atteint la durée de vie maximale de l’arrête de coupe.

3. Les copeaux peuvent devenir chauds et causer des lésions oculaires ou

des brûlures. Veuillez vous assurer que les protections de la machines sont

correctement utilisées, et que des lunettes et des gants soient portés pour tout

travail à proximité de l’outil ou de la pièce à usiner.

4. Prenez vos précautions lors d’utilisation d’huiles de coupes à cause des risques

d’incendie

1. Scegliere le condizioni migliori della tabella indicata.

2. Per evitare la rottura dell’utensile cambiate l´inserto prima di arrivare all’usura

massima.

3. I trucioli possono essere molto caldi durante il lavoro. Usate sempre i mezzi

di sicurezza (Occhiali, guanti, vetri di sicurezza…) durante il lavoro vicino

all’utensile o al materiale.

4. Attenzione al rischio di fiamma se durante il lavoro usate refrigerante a base di

olio.

AHU15 | Adjust of Cutting Conditions for Finishing

For finishing please adjust the cutting conditions as follows:

Vc

fz

0.1 mm

ap

~ 5 mm maximum

ae

Finishing

+50 %

0.3 ~ 0.5 mm

© 2009 Hitachi Tool Engineering Europe GmbH

Errors and alterations excepted · Änderungen und Irrtum vorbehalten

5

- 6. AHU15 | Recommended Cutting Conditions

ØD 32 / Z3 / modular type

Side

I

Mild steel

(<200HB)

II

Carbon steel; Alloy

JX1045

steel (<30HRC)

III

Carbon steel; Alloy JX1045

steel (30-40HRC) JX1020

IV

Pre-hardened

steel; Tool Steel

(40-50HRC)

JX1020

Stainless steel

(dry condition)

JX1045

Stainless steel

(wet condition)

JX1060

VIII

Cast Iron; GG;

GGG

JX1045

JX1020

*

Titanium Alloy

(wet condition)

JX1060

*

Aluminium Alloy

(wet condition)

JX1020

JX1045

VI

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

max. cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

220

2,189

0.25

1,642

10

9.6

158

220

2,189

0.25

1,642

8.5

9.6

134

154

1,533

0.2

920

7

9.6

62

110

1,095

0.15

493

5

9.6

24

330

3,284

0.25

2,463

8

9.6

189

154

1,533

0.25

1,149

8

9.6

88

220

2,189

0.25

1,642

10

9.6

158

66

657

0.2

394

10

9.6

38

660

6,568

0.25

4,926

10

9.6

473

Slotting

154

1,533

0.175

805

5

32

129

154

1,533

0.175

805

4.25

32

109

108

1,073

0.14

451

3.5

32

50

77

766

0.105

241

2.5

32

19

231

2,299

0.175

1,207

4

32

154

108

1,073

0.175

563

4

32

72

154

1,533

0.175

805

5

32

129

46

460

0.14

193

5

32

31

462

4,598

0.175

2,414

5

32

386

ØD 40/ Z4 / modular type

Side

Slotting

220

1,752

0.25

1,752

10

12

210

220

1,752

0.25

1,752

8.5

12

179

154

1,226

0.2

981

7

12

82

110

876

0.15

525

5

12

32

330

2,627

0.25

2,627

8

12

252

154

1,226

0.25

1,226

8

12

118

220

1,752

0.25

1,752

10

12

210

66

525

0.2

420

10

12

50

660

5,255

0.25

5,255

10

12

631

154

1,226

0.175

858

5

40

172

154

1,226

0.175

858

4.25

40

146

108

858

0.14

481

3.5

40

67

77

613

0.105

257

2.5

40

26

231

1,839

0.175

1,287

4

40

206

108

858

0.175

601

4

40

96

154

1,226

0.175

858

5

40

172

46

368

0.14

206

5

40

41

462

3,678

0.175

2,575

5

40

515

ØD 50 / Z5 / bore type

Side

220

1,401

0.25

1,752

10

15

263

220

1,401

0.25

1,752

8.5

15

223

154

981

0.2

981

7

15

103

110

701

0.15

525

5

15

39

330

2,102

0.25

2,627

8

15

315

154

981

0.25

1,226

8

15

147

220

1,401

0.25

1,752

10

15

263

66

420

0.2

420

10

15

63

660

4,204

0.25

5,255

10

15

788

Slotting

154

981

0.175

858

5

50

215

154

981

0.175

858

4.25

50

182

108

687

0.14

481

3.5

50

84

77

490

0.105

257

2.5

50

32

231

1,471

0.175

1,287

4

50

257

108

687

0.175

601

4

50

120

154

981

0.175

858

5

50

215

46

294

0.14

206

5

50

51

462

2,943

0.175

2,575

5

50

644

* Possible, please pay attention for reduced tool life.

6

© 2009 Hitachi Tool Engineering Europe GmbH

Errors and alterations excepted · Änderungen und Irrtum vorbehalten

- 7. AHU15 | Recommended Cutting Conditions

ØD 63 / Z6 / bore type

Side

I

Mild steel

(<200HB)

II

Carbon steel; Alloy

JX1045

steel (<30HRC)

III

Carbon steel; Alloy JX1045

steel (30-40HRC) JX1020

IV

Pre-hardened

steel; Tool Steel

(40-50HRC)

JX1045

JX1020

Stainless steel (dry

JX1045

condition)

VI

Stainless steel

(wet condition)

JX1060

VIII

Cast Iron; GG;

GGG

JX1045

JX1020

*

Titanium Alloy

(wet condition)

JX1060

*

Aluminium Alloy

(wet condition)

JX1020

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

max. cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

Vc (m/min)

n (min-1)

fz (mm/tooth)

Vf (mm/min)

ap (mm) max.

ae (mm) max.

cm3

220

1,112

0.25

1,668

10

18.9

315

220

1,112

0.25

1,668

8.5

18.9

268

154

778

0.2

934

7

18.9

124

110

556

0.15

500

5

18.9

47

330

1,668

0.25

2,502

8

18.9

378

154

778

0.25

1,168

8

18.9

177

220

1,112

0.25

1,668

10

18.9

315

66

334

0.2

400

10

18.9

76

660

3,336

0.25

5,005

10

18.9

946

Slotting

154

778

0.175

817

5

63

257

154

778

0.175

817

4.25

63

219

108

545

0.14

458

3.5

63

101

77

389

0.105

245

2.5

63

39

231

1,168

0.175

1,226

4

63

309

108

545

0.175

572

4

63

144

154

778

0.175

817

5

63

257

46

234

0.14

196

5

63

62

462

2,335

0.175

2,452

5

63

772

ØD 80 / Z7 / bore type

Side

220

876

0.25

1,533

10

24

368

220

876

0.25

1,533

8.5

24

313

154

613

0.2

858

7

24

144

110

438

0.15

460

5

24

55

330

1,314

0.25

2,299

8

24

441

154

613

0.25

1,073

8

24

206

220

876

0.25

1,533

10

24

368

66

263

0.2

368

10

24

88

660

2,627

0.25

4,598

10

24

1,104

Slotting

154

613

0.175

751

5

80

300

154

613

0.175

751

4.25

80

255

108

429

0.14

421

3.5

80

118

77

307

0.105

225

2.5

80

45

231

920

0.175

1,126

4

80

360

108

429

0.175

526

4

80

168

154

613

0.175

751

5

80

300

46

184

0.14

180

5

80

72

462

1,839

0.175

2,253

5

80

901

ØD 100 / Z8 / bore type

Side

220

701

0.25

1,401

10

30

420

220

701

0.25

1,401

8.5

30

357

154

490

0.2

785

7

30

165

110

350

0.15

420

5

30

63

330

1,051

0.25

2,102

8

30

504

154

490

0.25

981

8

30

235

220

701

0.25

1,401

10

30

420

66

210

0.2

336

10

30

101

660

2,102

0.25

4,204

10

30

1,261

Slotting

154

490

0.175

687

5

100

343

154

490

0.175

687

4.25

100

292

108

343

0.14

385

3.5

100

135

77

245

0.105

206

2.5

100

51

231

736

0.175

1,030

4

100

412

108

343

0.175

481

4

100

192

154

490

0.175

687

5

100

343

46

147

0.14

165

5

100

82

462

1,471

0.175

2,060

5

100

1,030

* Possible, please pay attention for reduced tool life.

© 2009 Hitachi Tool Engineering Europe GmbH

Errors and alterations excepted · Änderungen und Irrtum vorbehalten

7

- 8. Product Range

Solid Carbide End Mills

Indexable Milling Tools

ESM Speed End Mills

EMC Power Drills

Milling Chucks

Hitachi Tool Engineering Europe GmbH

Itterpark 12 · 40724 Hilden · Germany · Phone +49 (0) 21 03 – 24 82-0 · Fax +49 (0) 21 03 – 24 82-30

e-Mail info@hitachitool-eu.com · Internet www.hitachitool-eu.com

© 2009 by Hitachi Tool Engineering Europe GmbH · Printed in Germany

HTT338 0903 AHU-5.0 BW-DS

Distributed by: