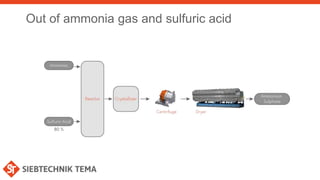

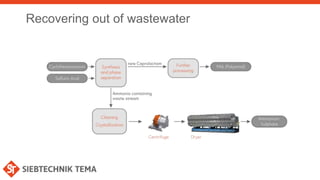

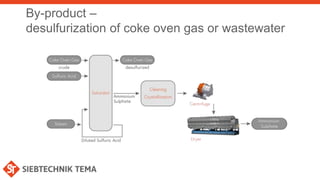

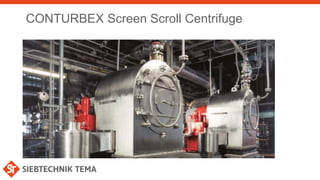

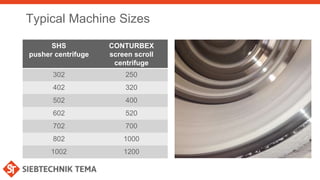

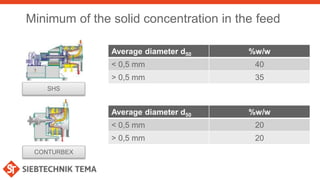

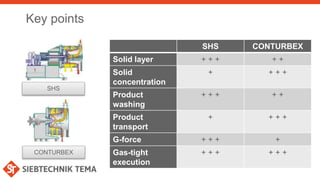

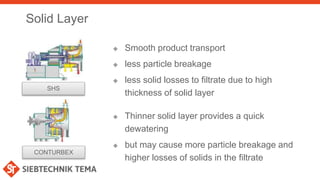

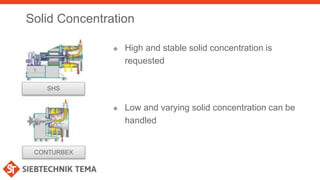

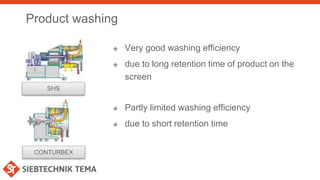

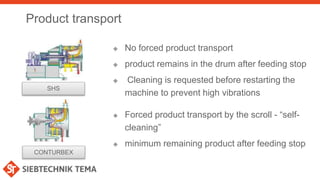

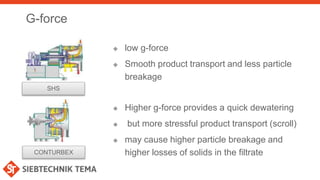

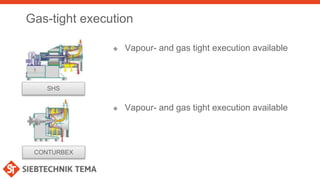

Ammonium sulfate is an inorganic salt primarily used as a soil fertilizer, food additive, and for drinking water treatment. It is produced from ammonia gas and sulfuric acid, and its production processes involve various centrifugation techniques. Key production equipment includes SHS and Conturbex centrifuges, which differ in solid concentration handling, product transport methods, and particle breakage rates.