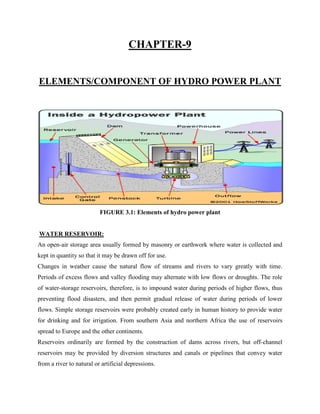

The document provides background information on Tehri Hydro Development Corporation (THDC) in India. It discusses the history and formation of THDC, which was established in 1988 to develop, operate, and maintain the 2400 MW Tehri Hydro Power Complex and other hydro projects. It describes some of THDC's key hydroelectric projects in India and Bhutan, including the 1000 MW Tehri Dam & HPP, 400 MW Koteshwar HEP, and 180 MW Bunakha HEP in Bhutan. It also provides an overview of THDC's operations, financial performance, certifications, and installed generation capacity.