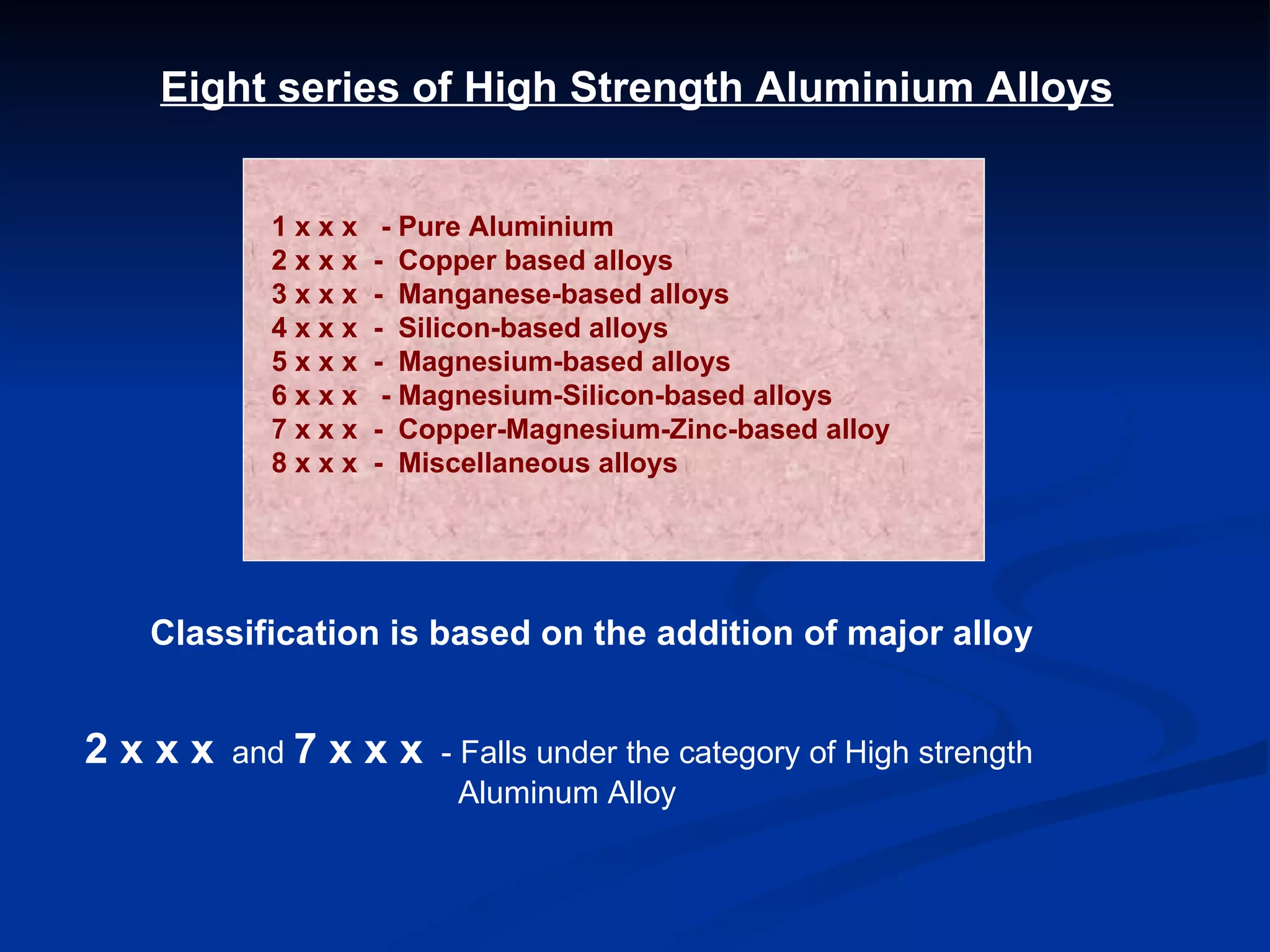

This document discusses opportunities and challenges in the extrusion of high-strength aluminum alloys for defense applications. It notes that only a few private players currently produce these alloys to meet defense needs. Key challenges include developing new alloy technologies, requiring large capital investments, and meeting stringent quality testing requirements for aircraft. However, demand is growing rapidly due to increases in defense spending, aerospace, and other strategic sectors.