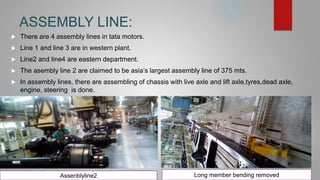

Arpit Kumar completed a summer training project at Tata Motors in Lucknow from June 21st to July 19th. The project involved process validation of critical and major processes on Trim Line 2. Trim Line 2 assembles cowls and cabs before passing them to assembly lines. Arpit analyzed processes like steering fitment and torque validation to ensure quality and safety. He concluded that the experience provided valuable lessons in teamwork, problem solving, and industry experience to support his future career.