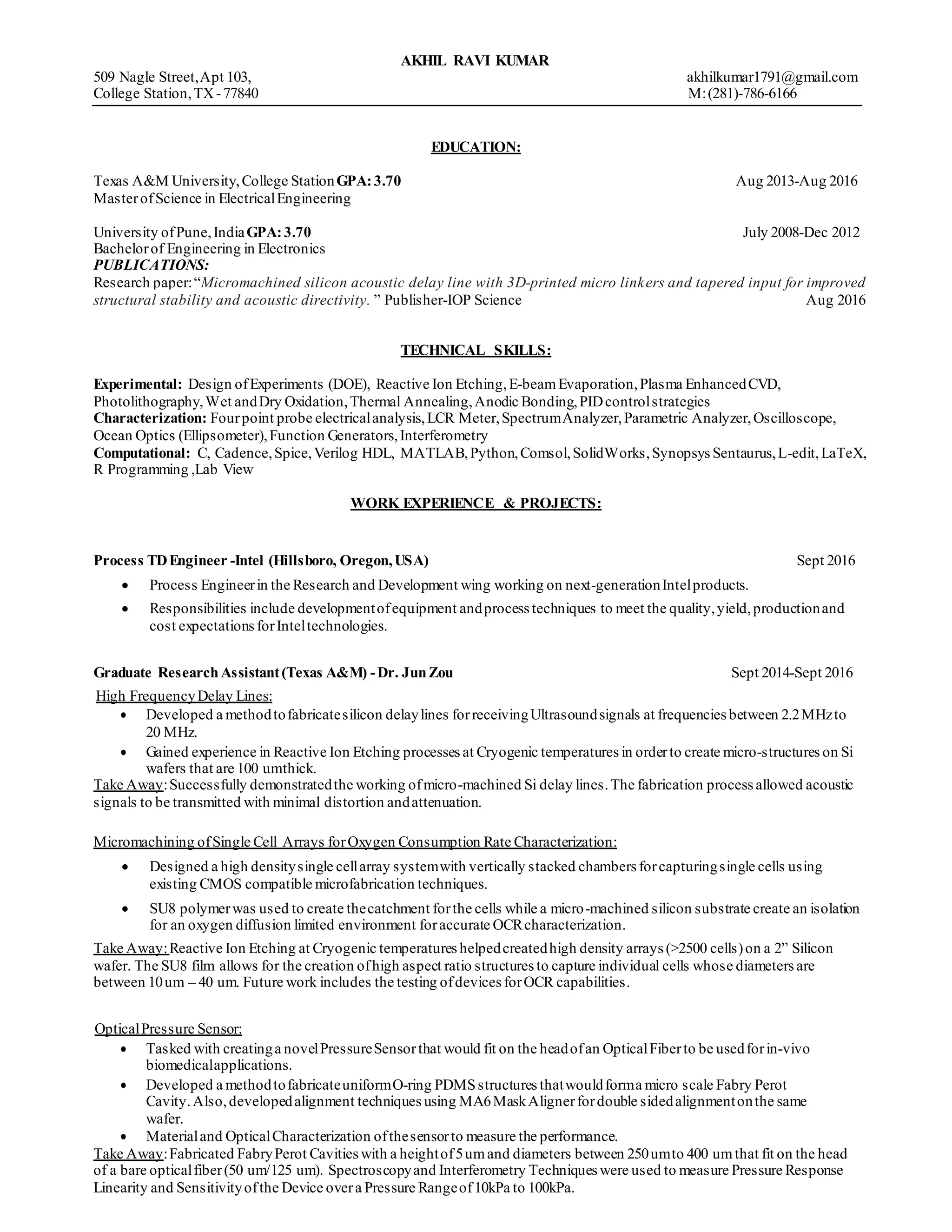

Akhil Ravi Kumar is seeking a position in electrical engineering. He received his Master's degree in electrical engineering from Texas A&M University and his Bachelor's degree from the University of Pune in India. He has work experience as a process engineer at Intel and research experience developing microfabrication techniques and sensors. His skills include microfabrication processes, characterization tools, programming languages, and CAD tools for circuit design.