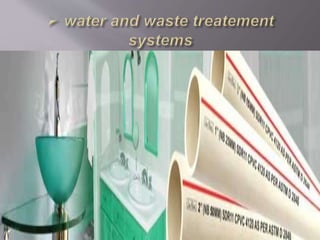

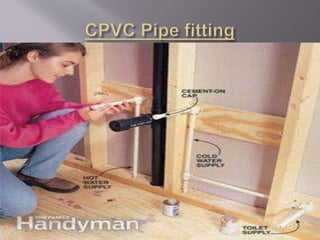

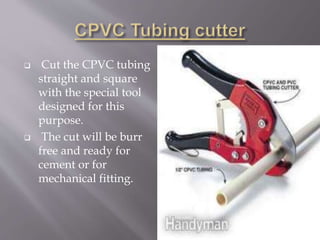

The document discusses CPVC pipes and provides information about their applications, advantages, standards, and installation process. It notes that CPVC pipes are ideal for plumbing applications as they are corrosion resistant, durable, and resistant to bacterial growth. The document outlines the standards that govern CPVC pipes for potable water supply and their use in building construction. It also provides brief steps for cutting and joining CPVC pipes during installation.