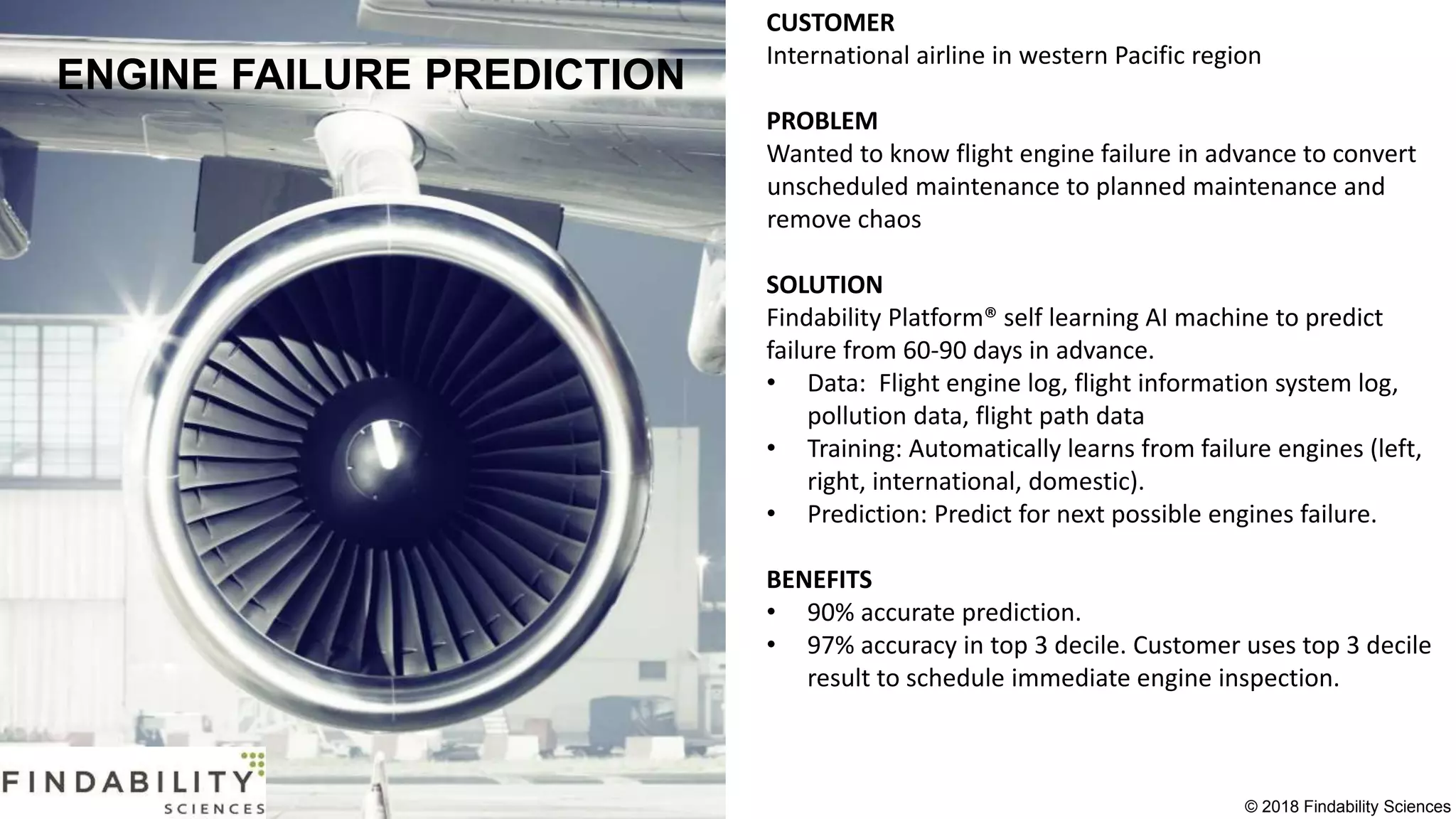

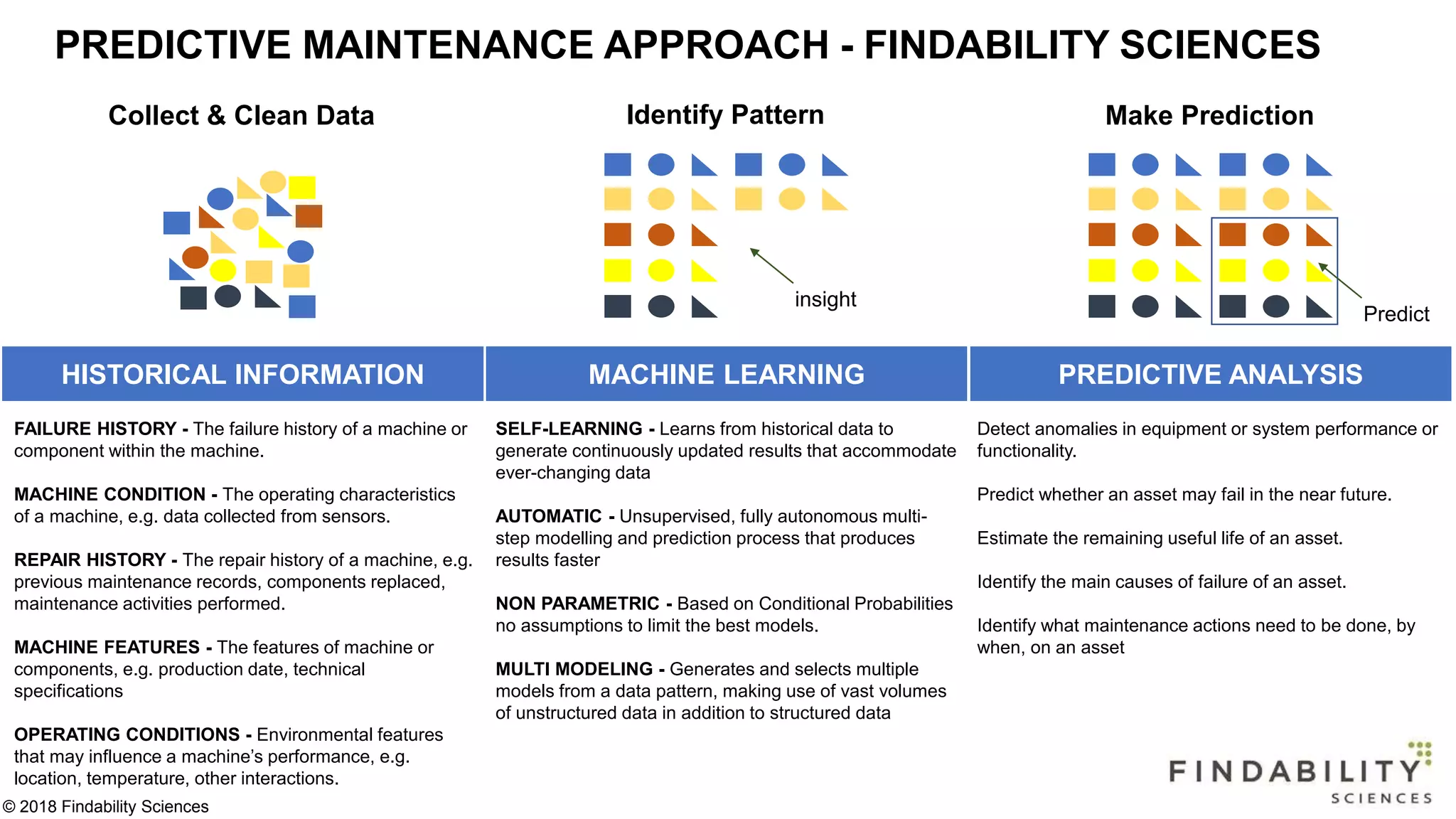

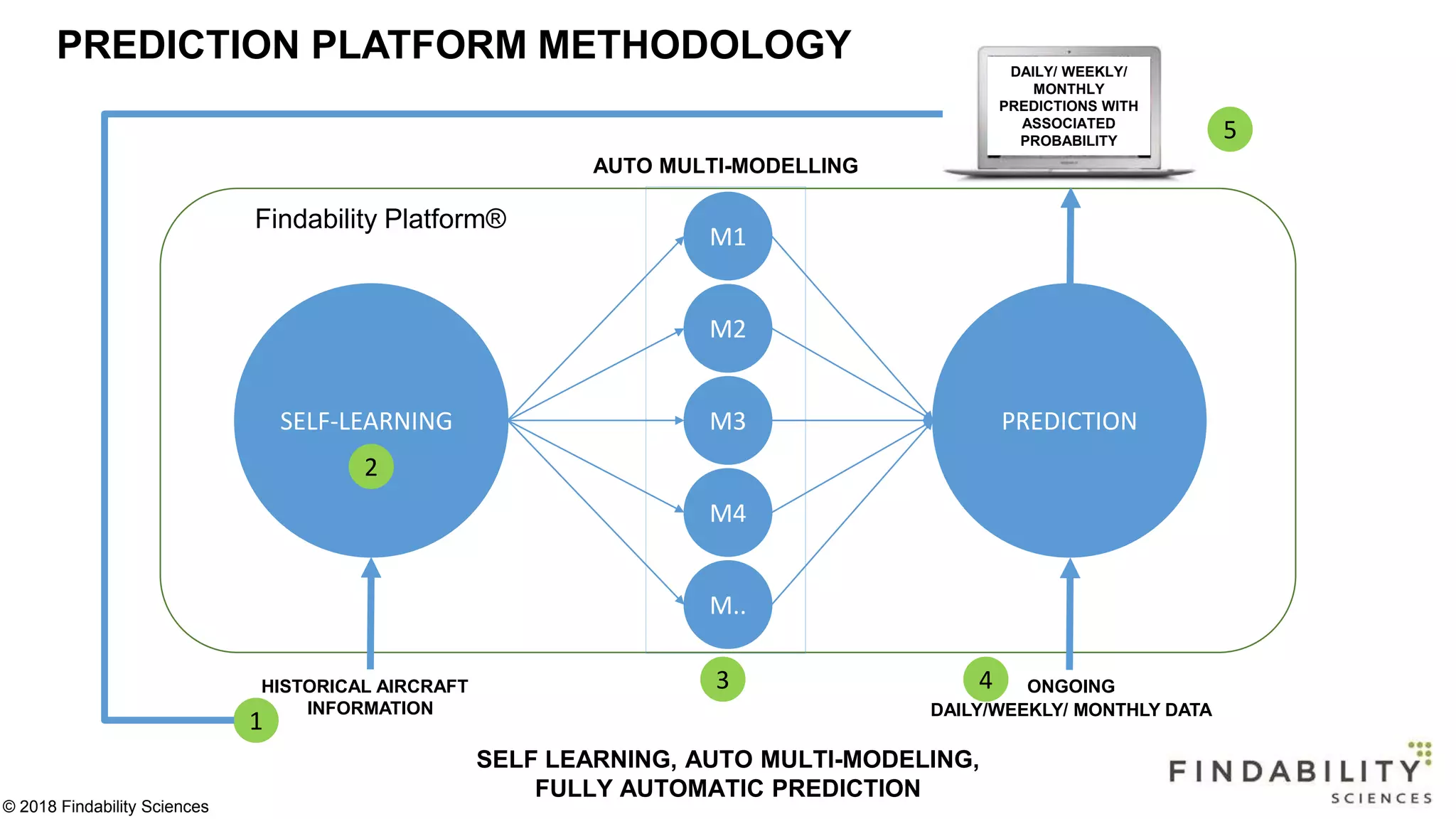

Findability Sciences offers an AI-powered predictive maintenance platform that integrates various data types to forecast equipment failures across multiple industries, including aviation. Their self-learning algorithms enable accurate predictions of component failures, significantly reducing maintenance costs and improving fleet reliability. The solution also features automatic data processing and model generation, allowing for continuous improvement and adaptability to changing data conditions.