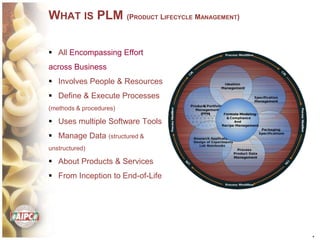

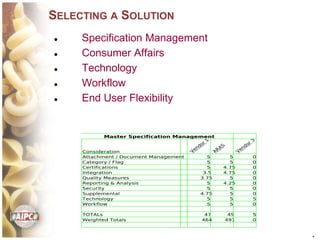

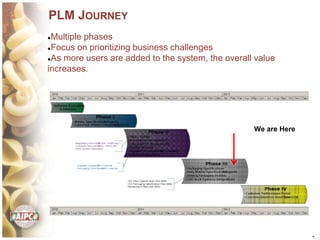

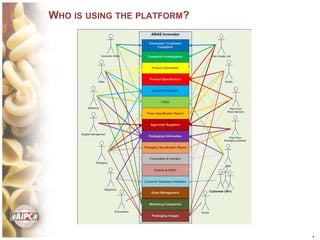

American Italian Pasta Company (AIPC) faced business challenges around managing product specifications and consumer complaints due to disparate data sources and inefficient legacy systems. AIPC implemented Aras Innovator as a product lifecycle management solution to provide an integrated framework for data management with orchestrated processes and support for multiple owners. This has led to improved data quality, reduced time spent on tasks like managing specifications and complaints, and increased support for analysis. AIPC's journey with Aras Innovator is ongoing as they continue adding users to further increase the value of shared data.