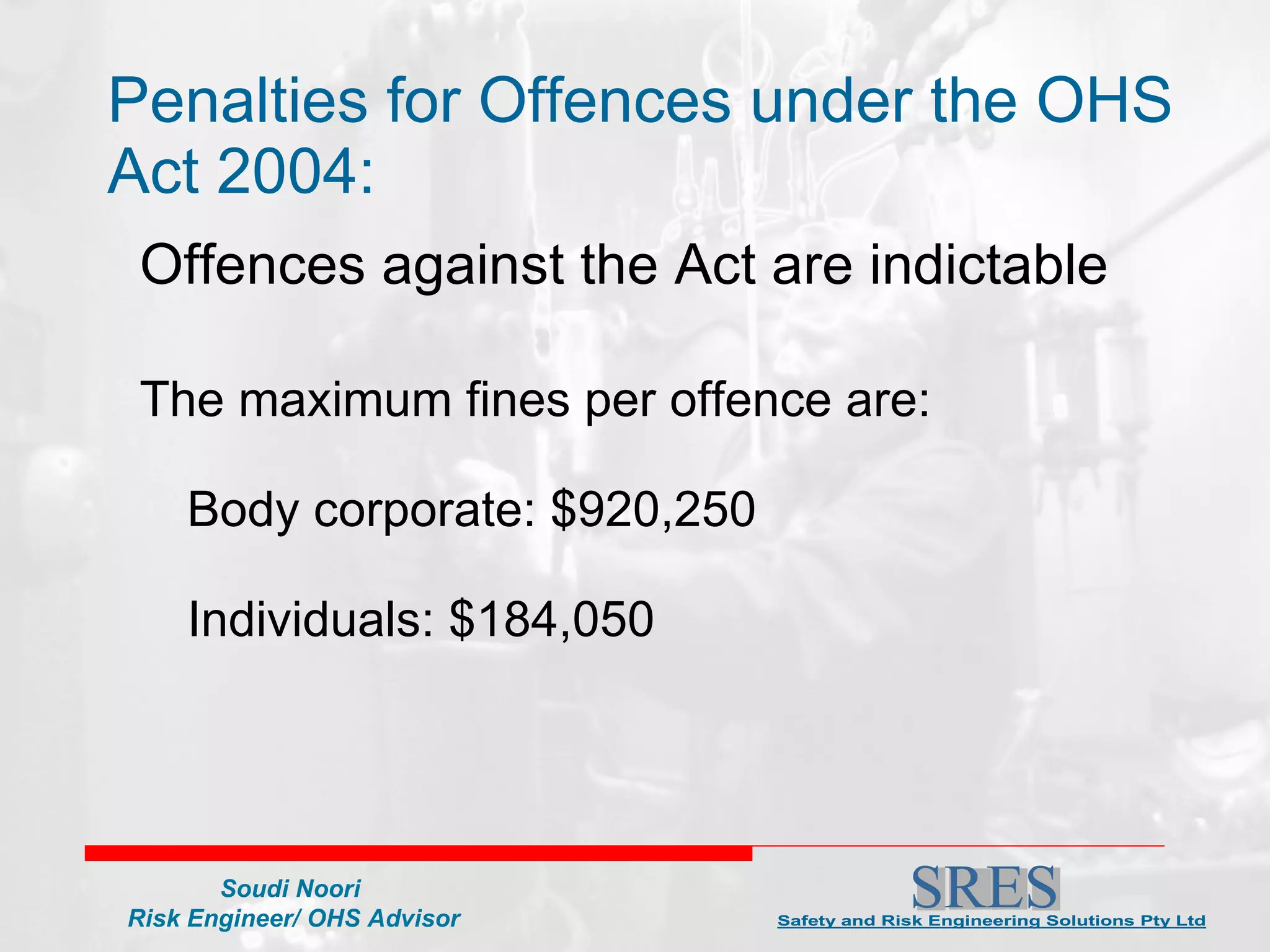

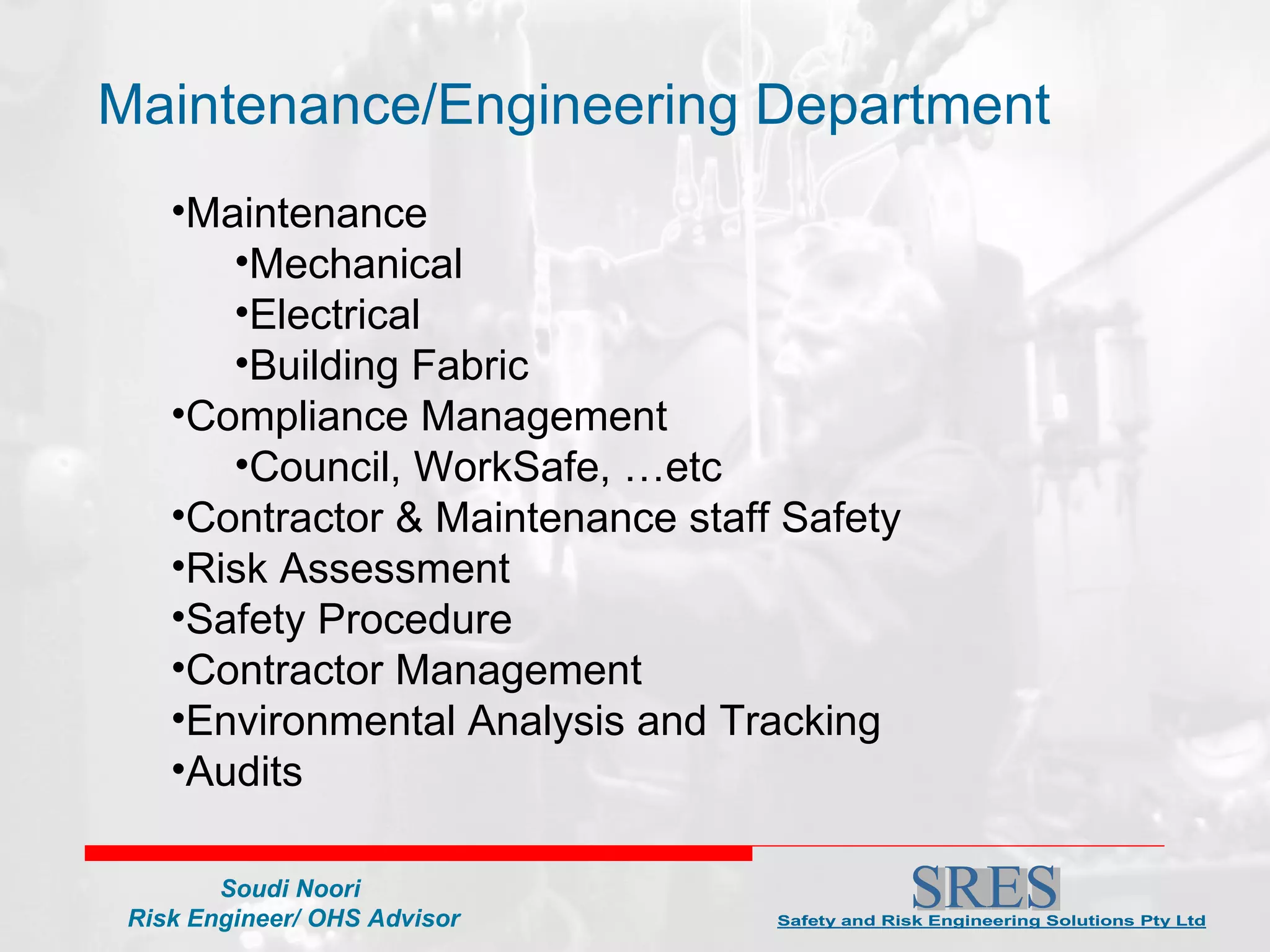

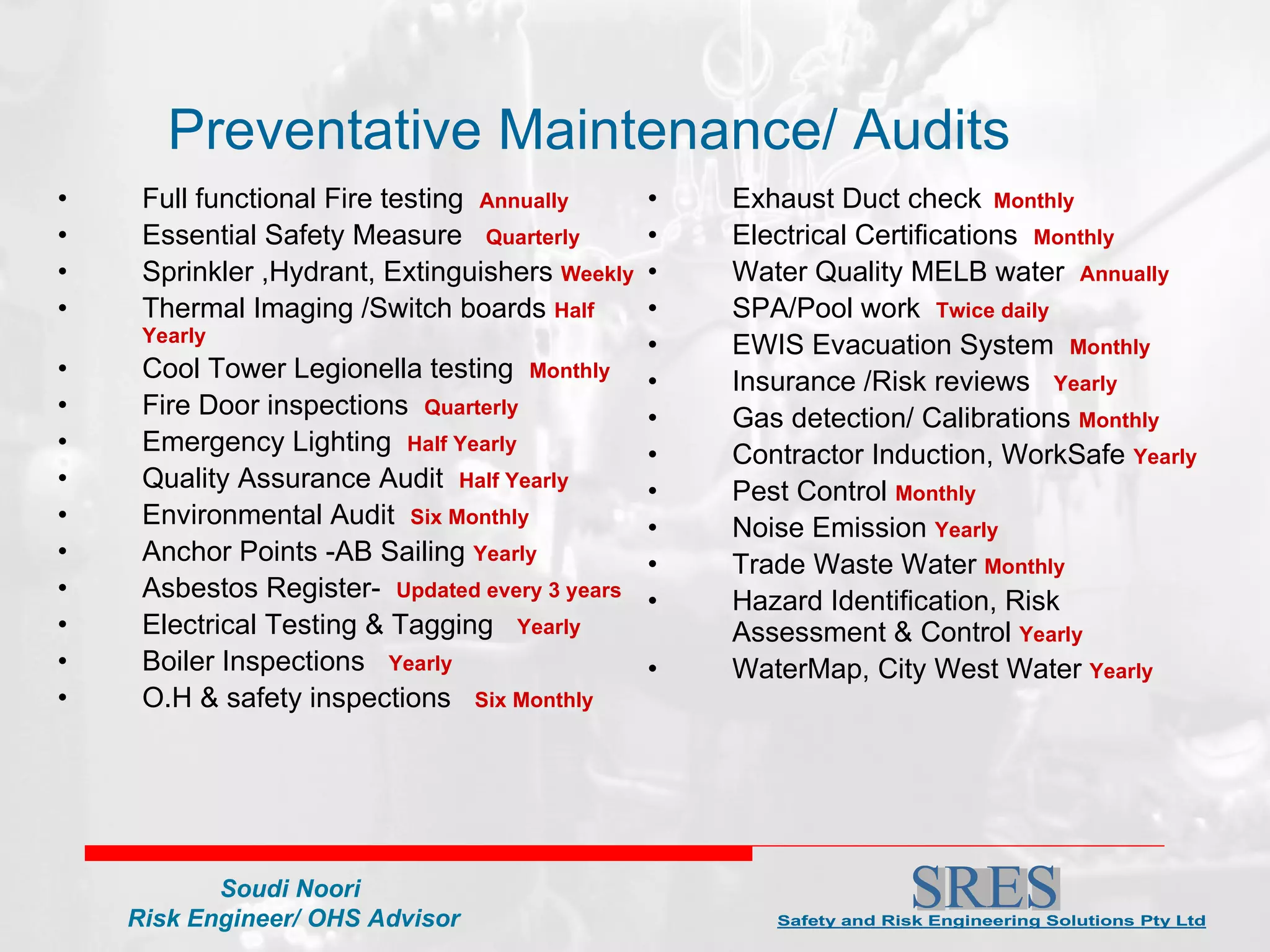

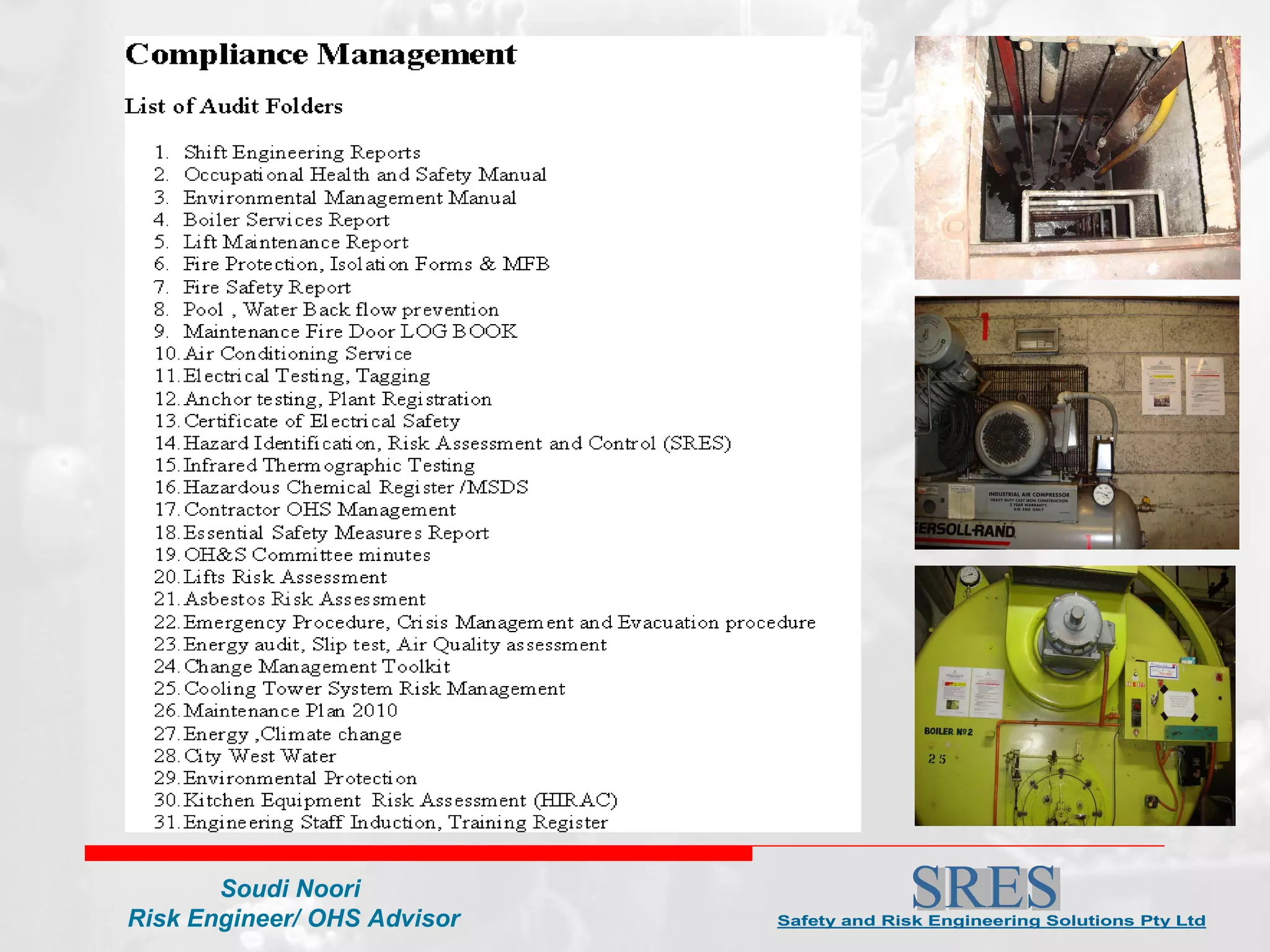

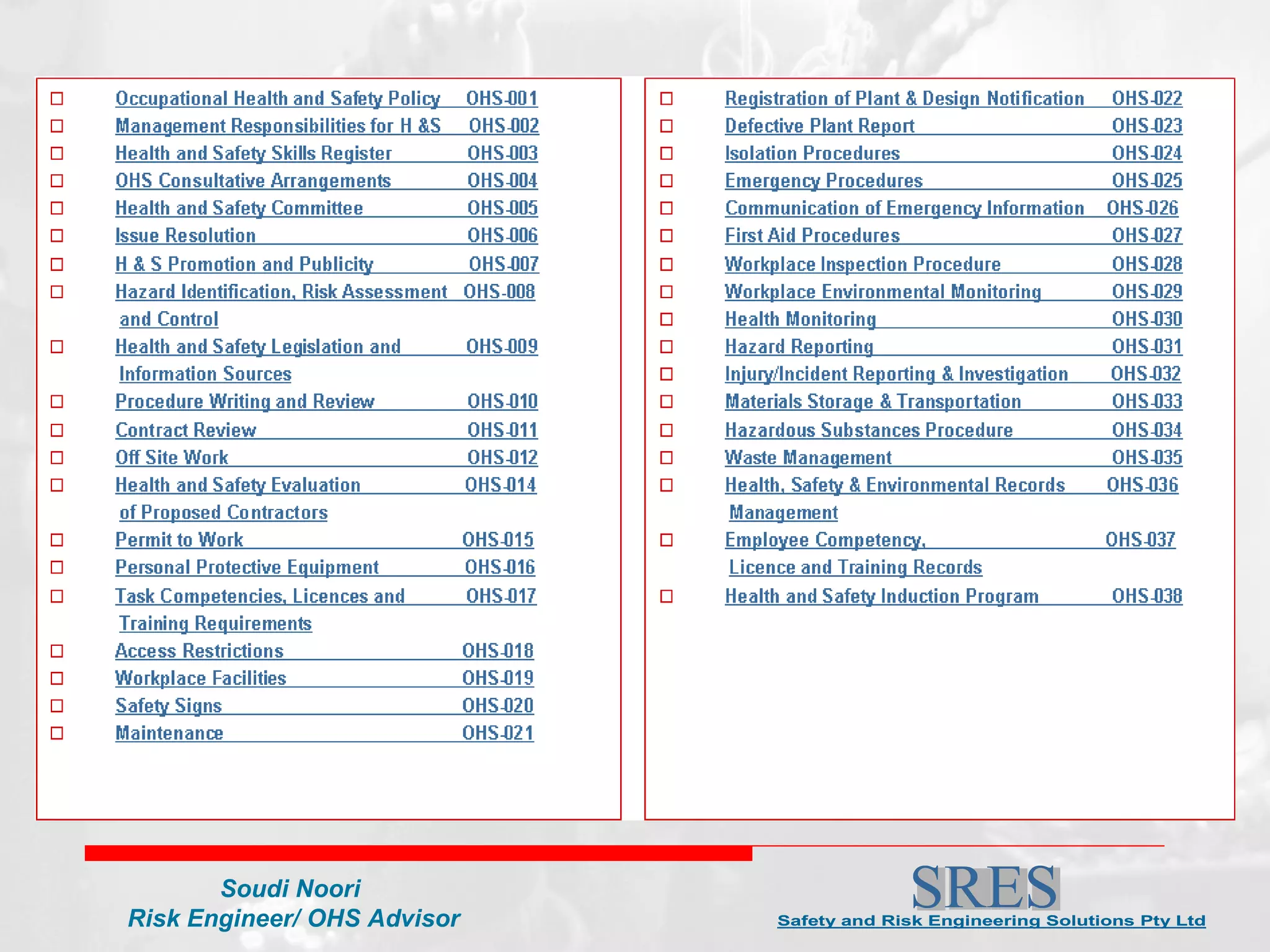

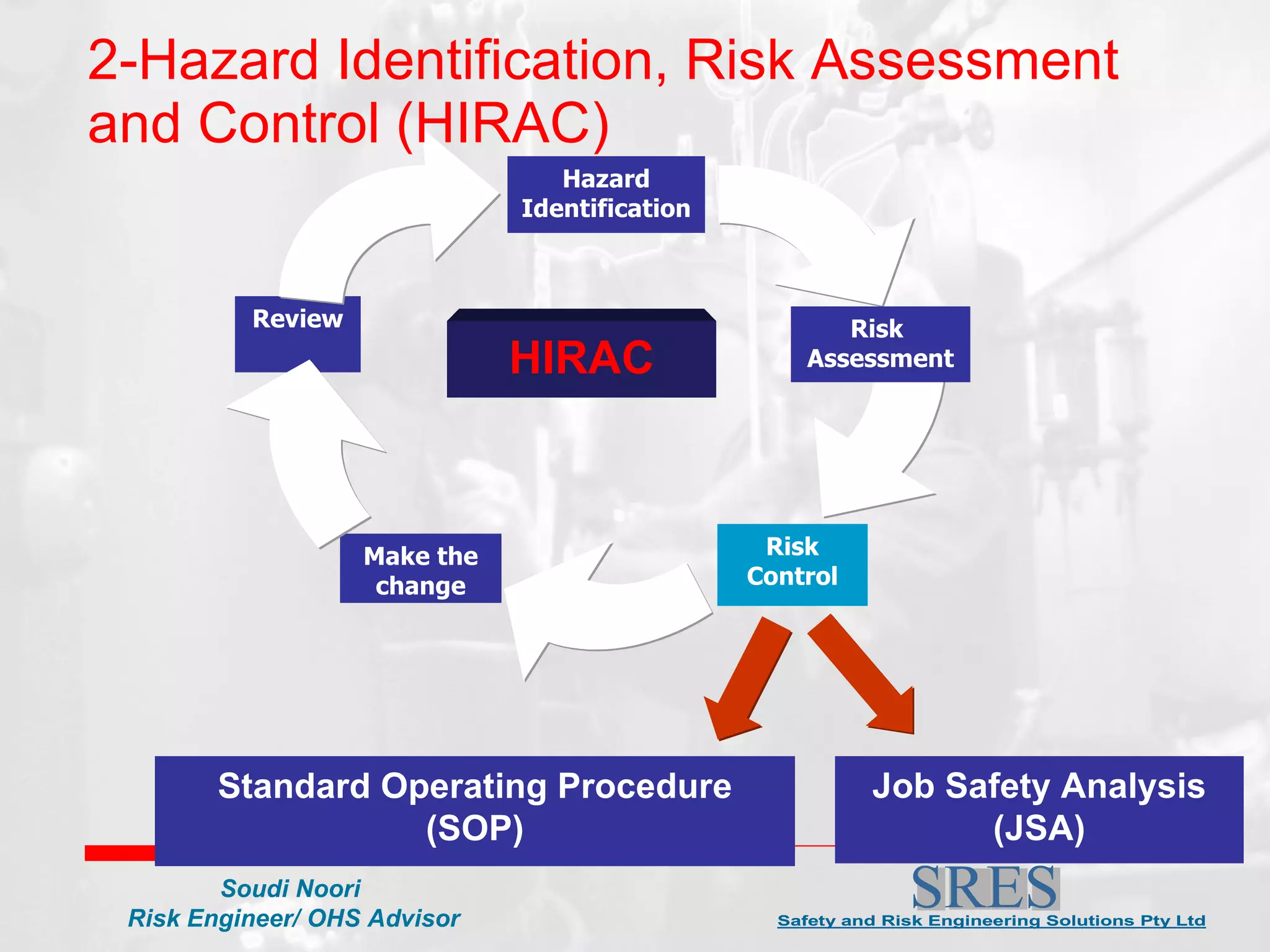

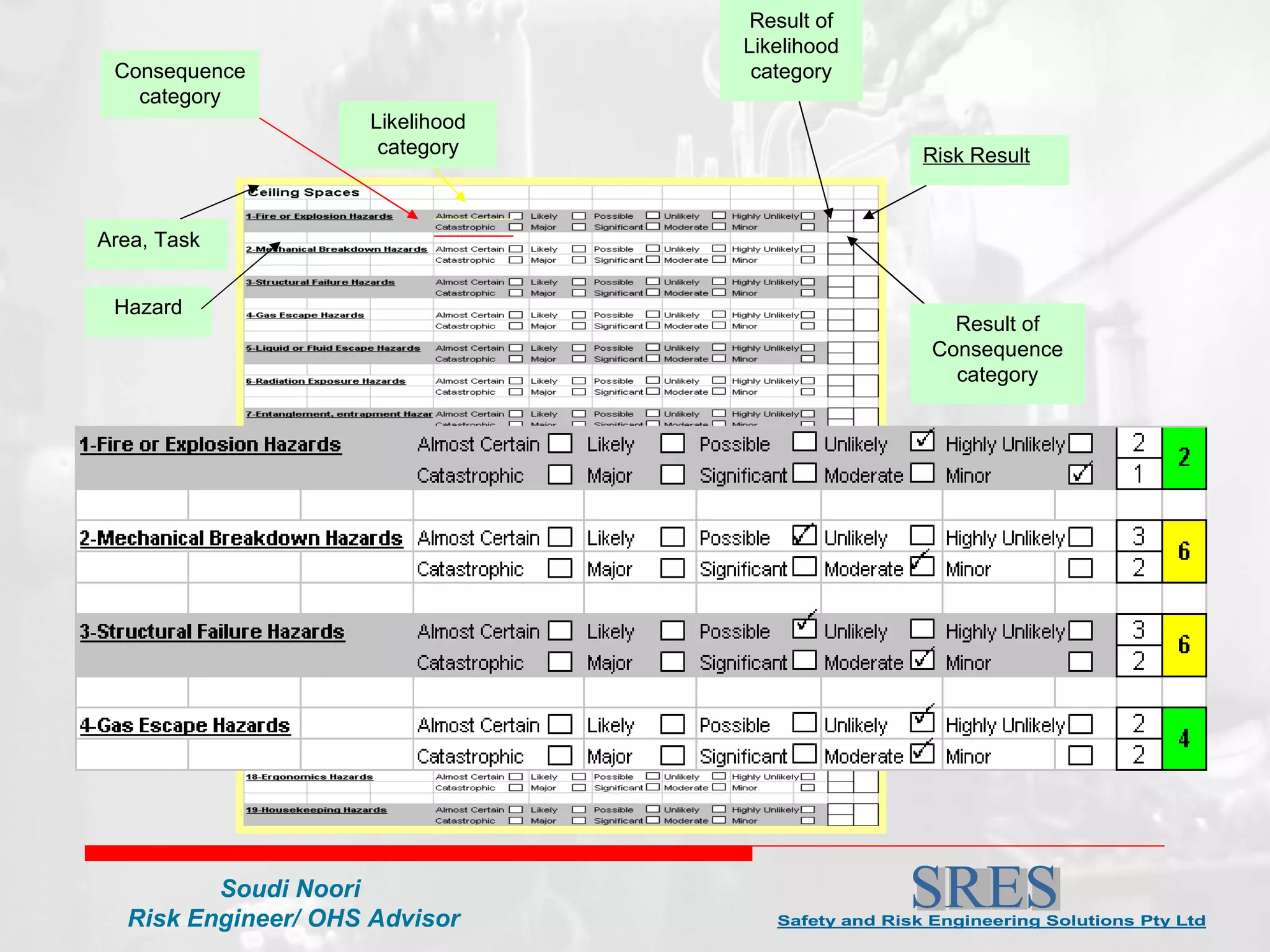

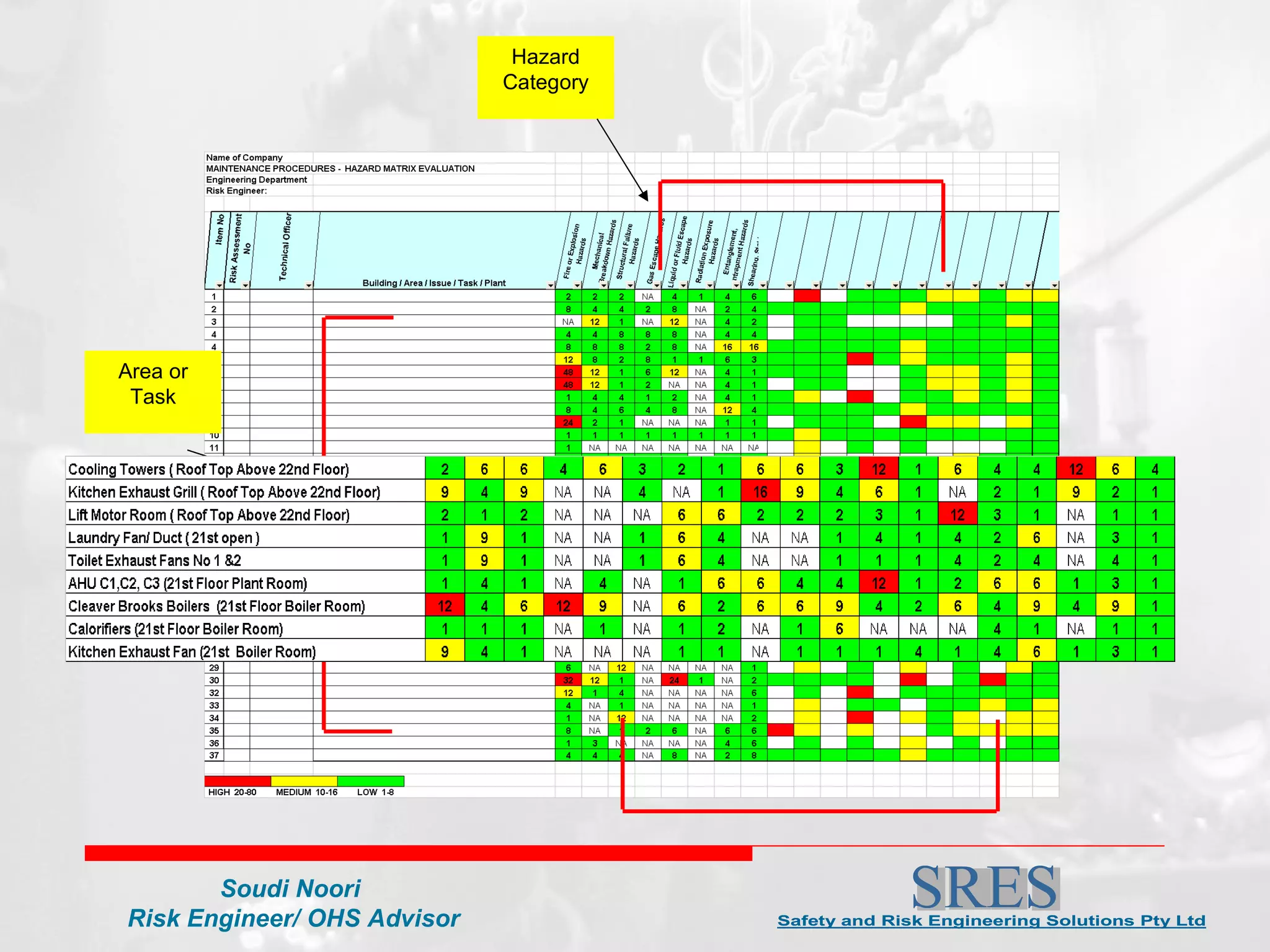

The document discusses occupational health and safety (OHS) in facilities and hotels. It provides statistics on work-related deaths and injuries in Australia. It then outlines the duties of employers and employees under the Occupational Health and Safety Act 2004, including maintaining a safe work environment, providing training, and taking reasonable care. The document proposes that Safety and Risk Engineering Solutions can help achieve OHS goals through implementing an OHS management system, hazard identification and risk assessments, and managing contractors on site.