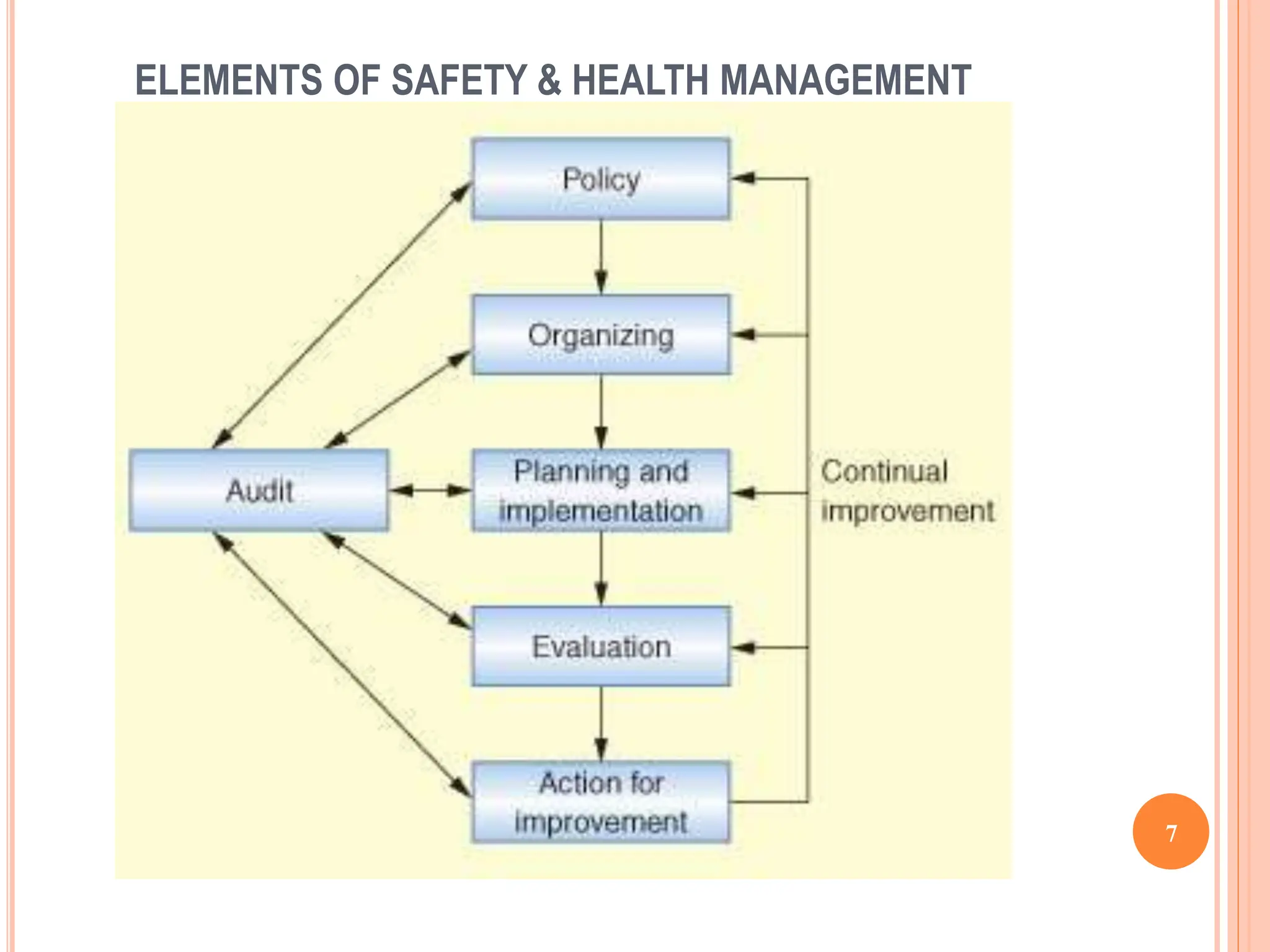

The document defines key terms related to occupational safety and health such as safety, health, and occupational safety and health management systems. It discusses why occupational health and safety is important at workplaces from moral, economic, and legal perspectives. It also outlines the key elements of an occupational safety and health management system including policy formulation, worker participation, management of change, organizing, documentation, planning and implementation, hazard prevention and control, emergency preparedness, procurement, evaluation, and continuous improvement. Finally, it provides an overview of the Occupational Safety and Health Act of 2007 and the duties it places on occupiers and employees.