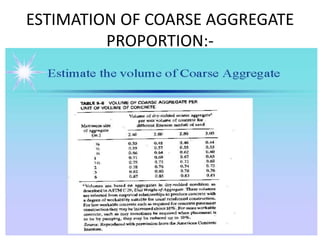

Aggregate is a collective term for materials like sand, gravel, and crushed stone that are used with a binding medium like cement or asphalt to form construction materials. Aggregates can be natural or manufactured. Fine aggregates pass through a 4.75 mm sieve while coarse aggregates are retained on the sieve. Common types of fine aggregates are natural sand, crushed stone sand, and crushed gravel sand. Common types of coarse aggregates include crushed gravel, uncrushed gravel, and partially crushed gravel. The proportion of fine and coarse aggregates in concrete is estimated using methods that account for the volumes and specific gravities of cement, water, and chemical admixtures.