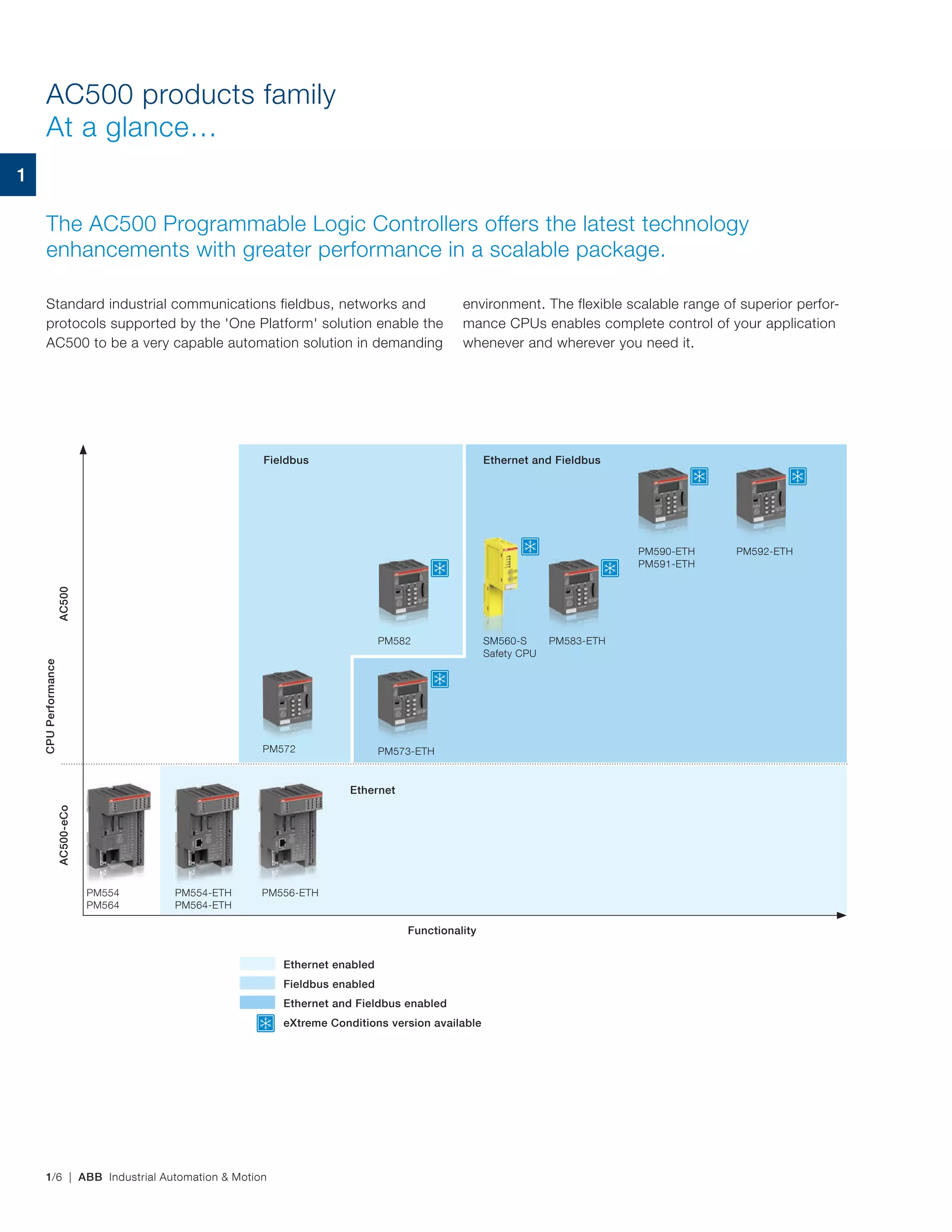

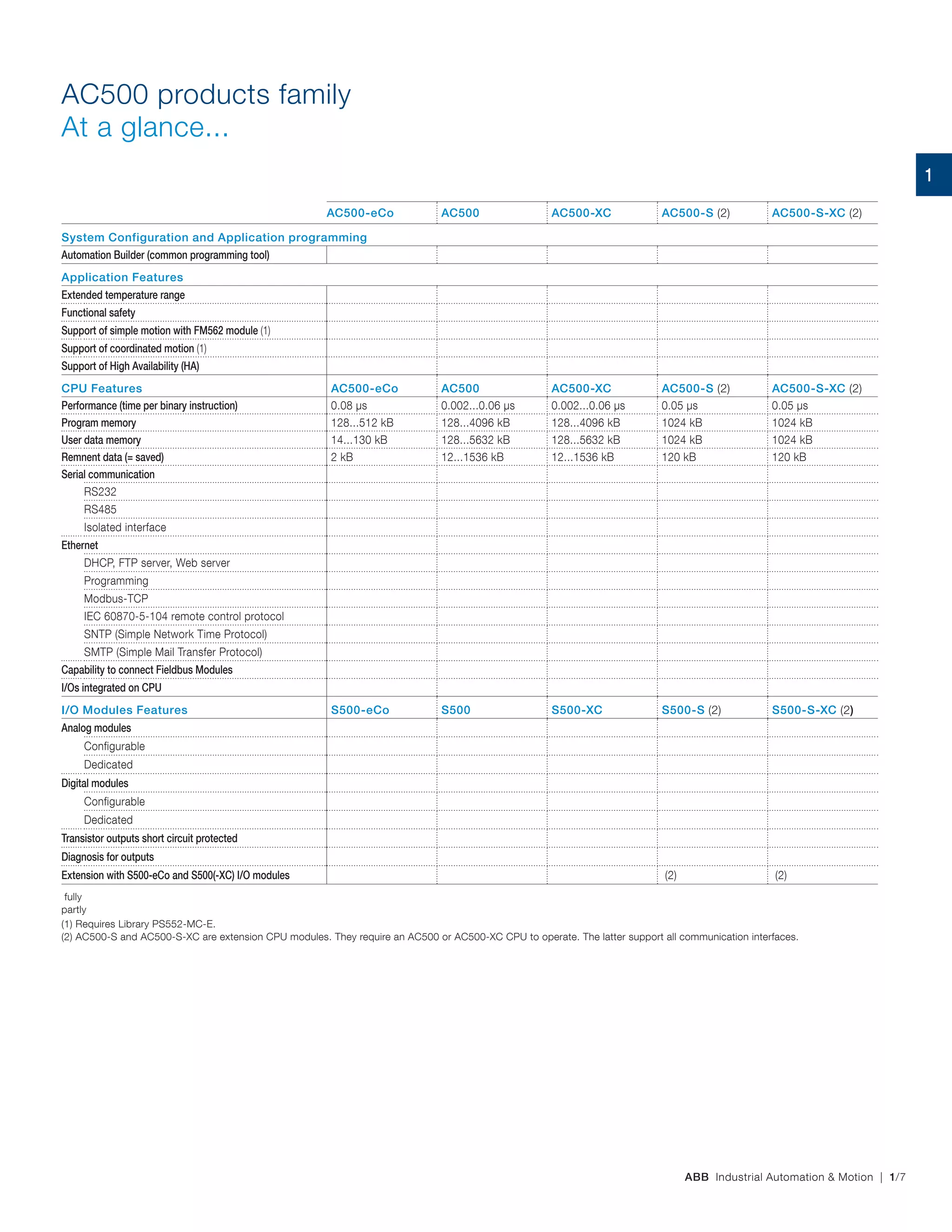

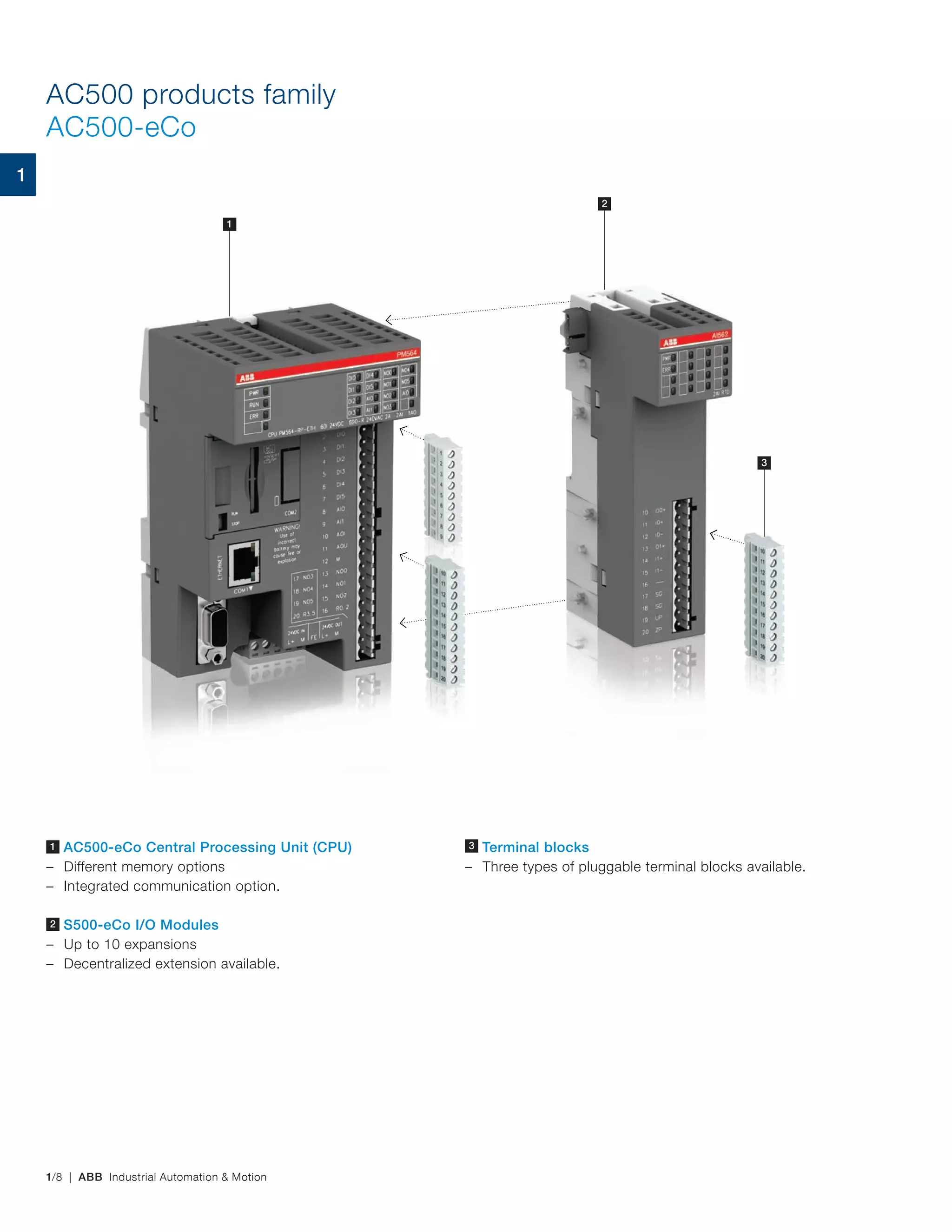

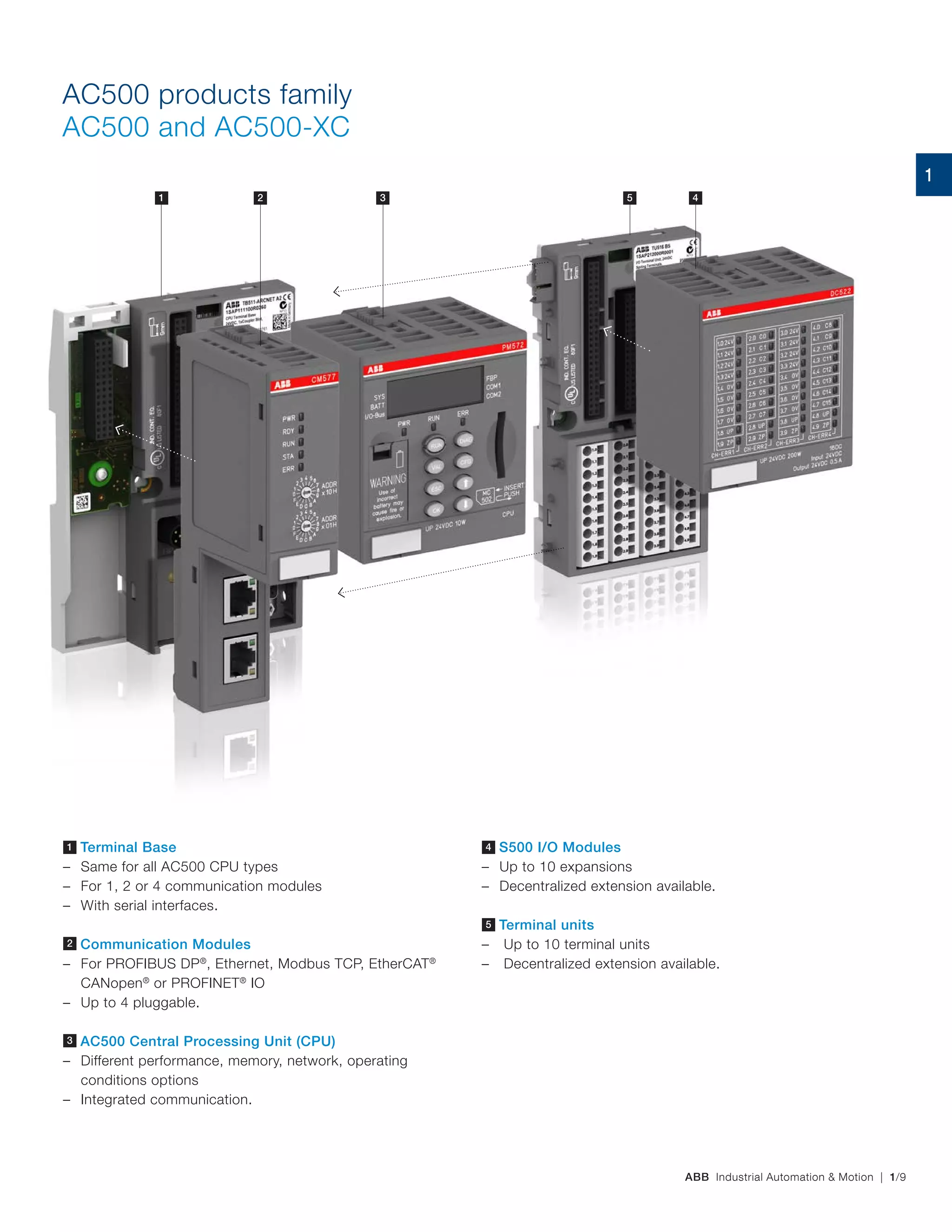

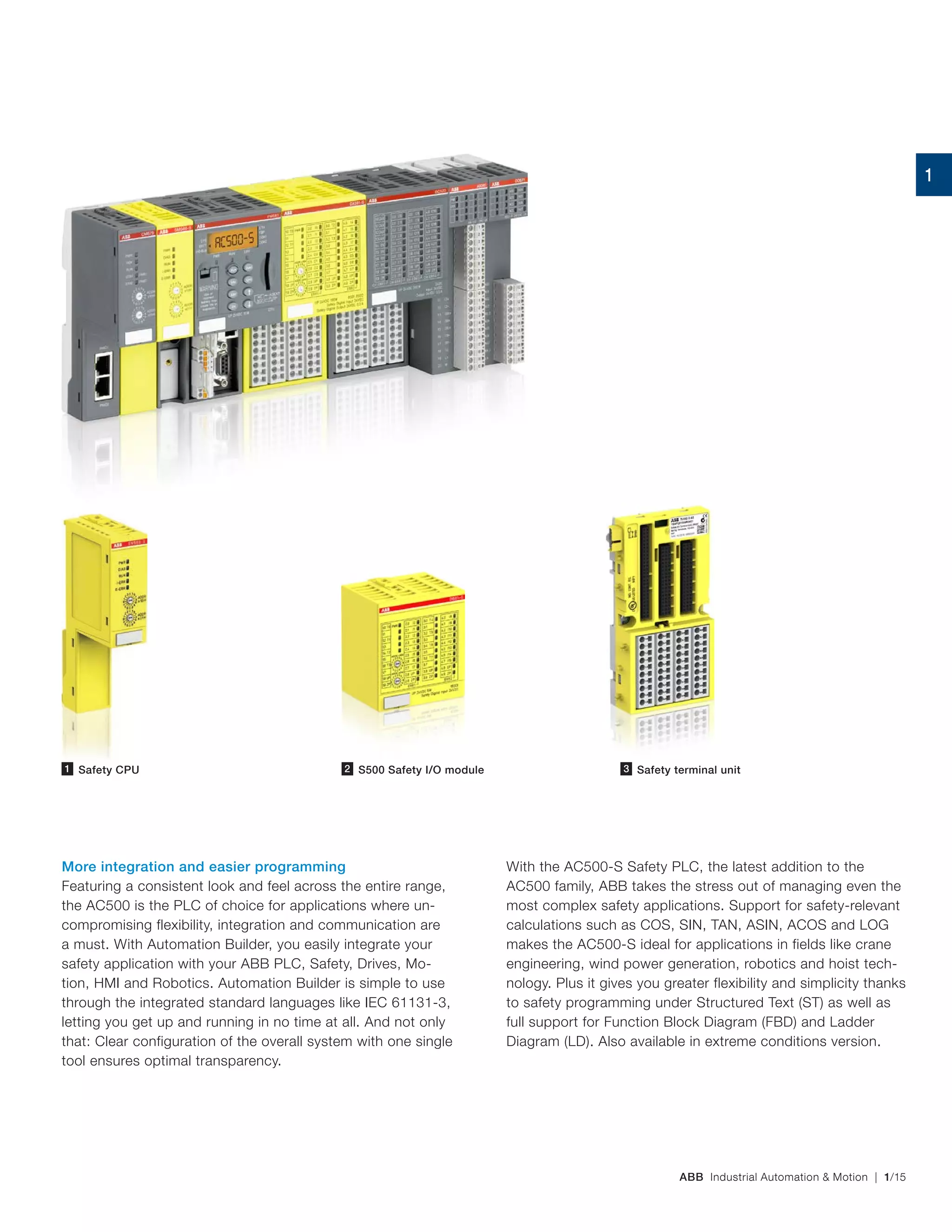

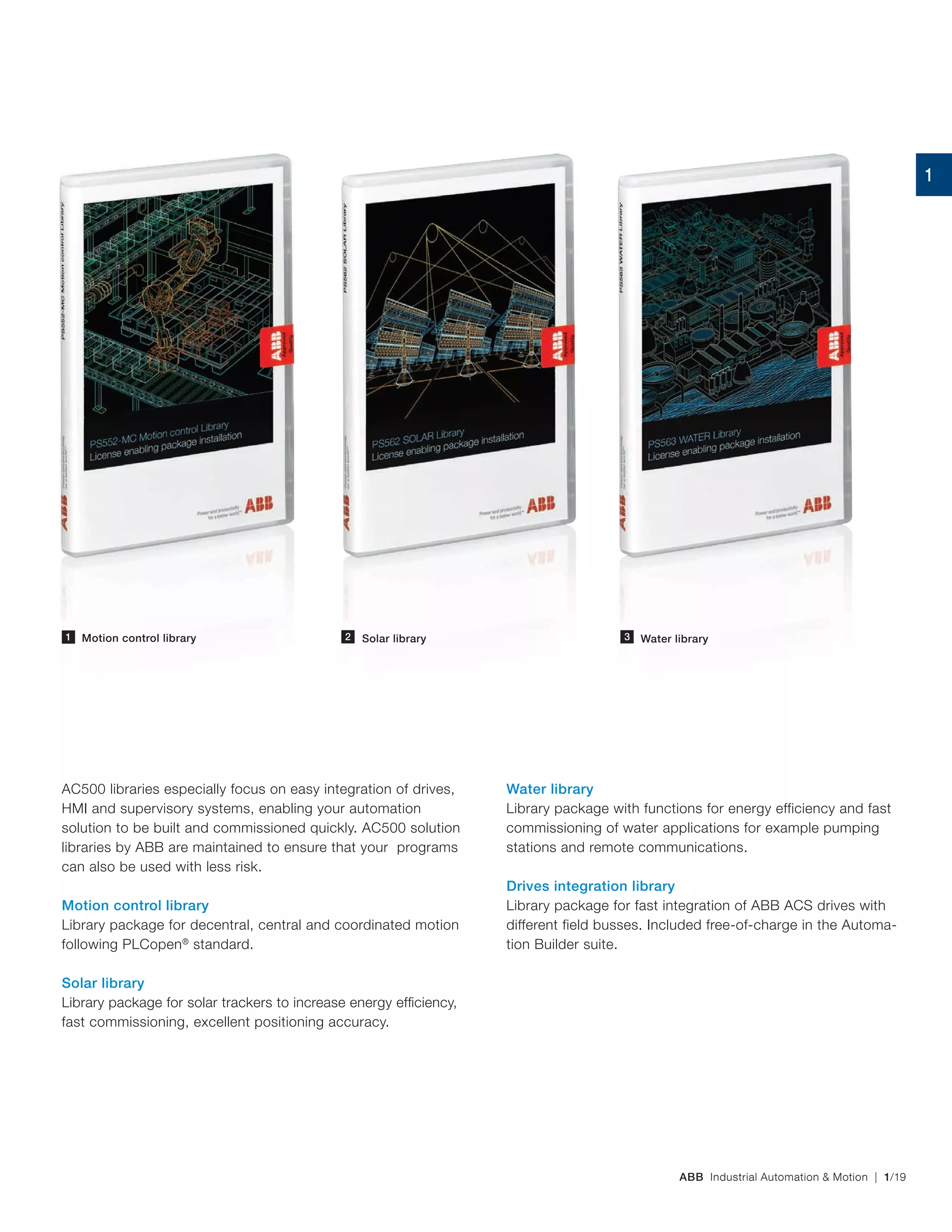

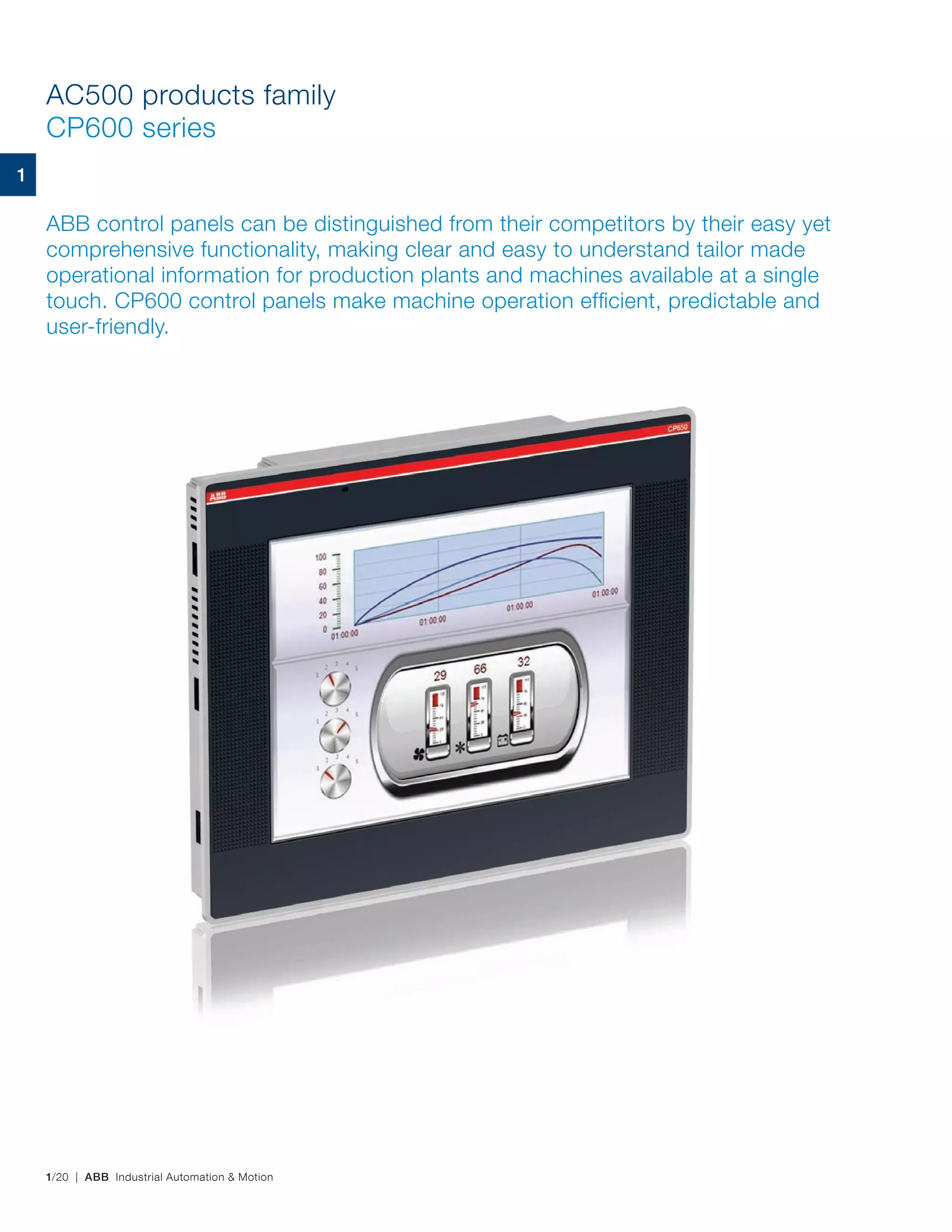

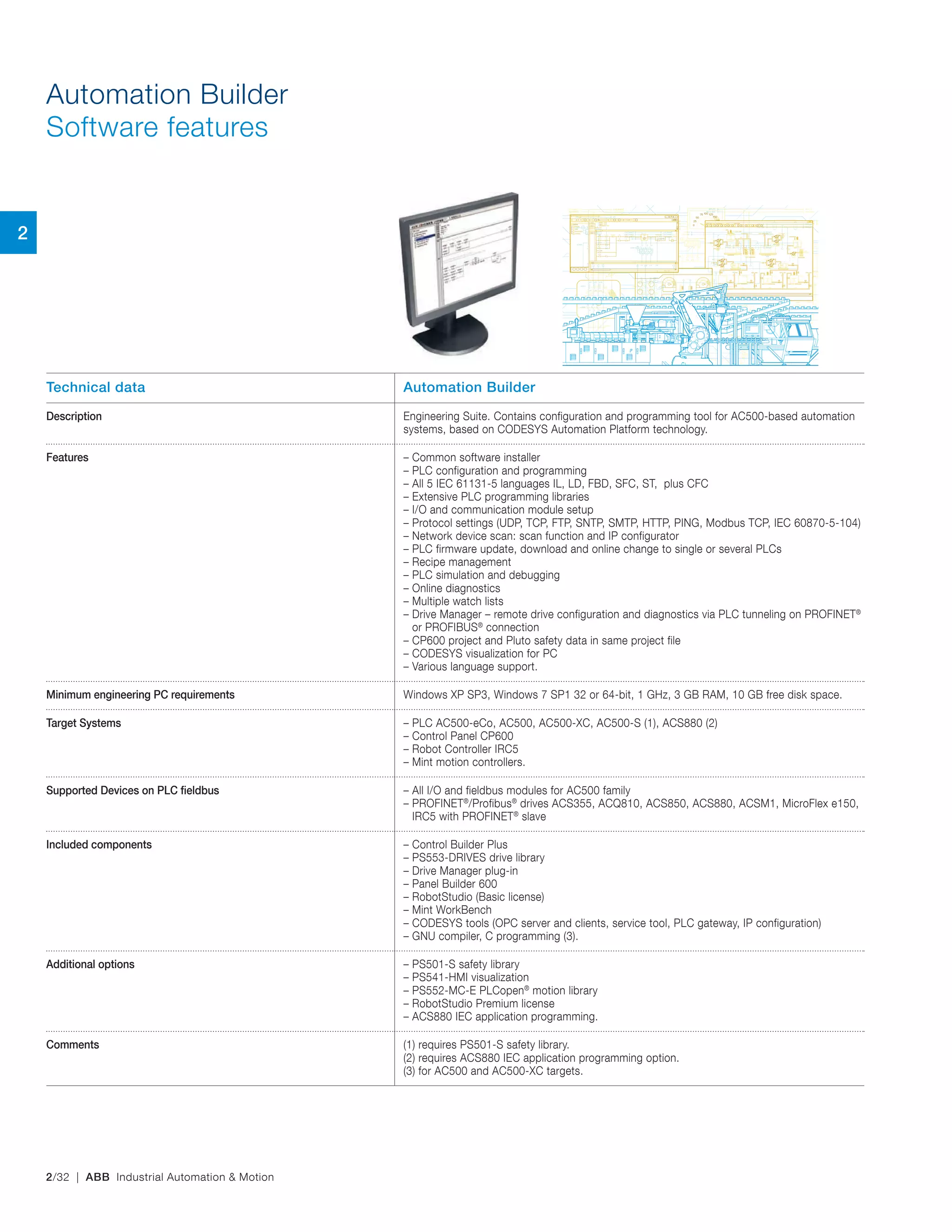

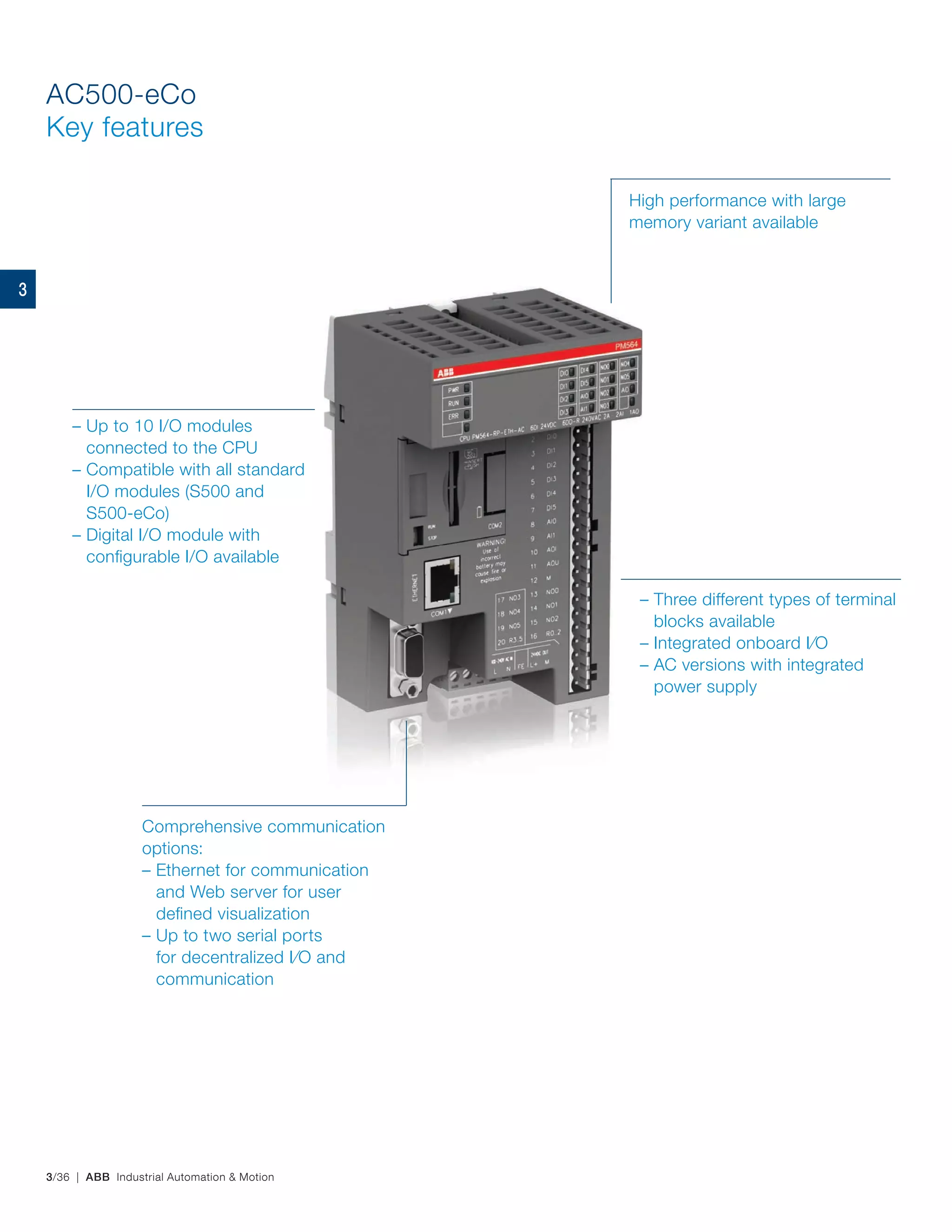

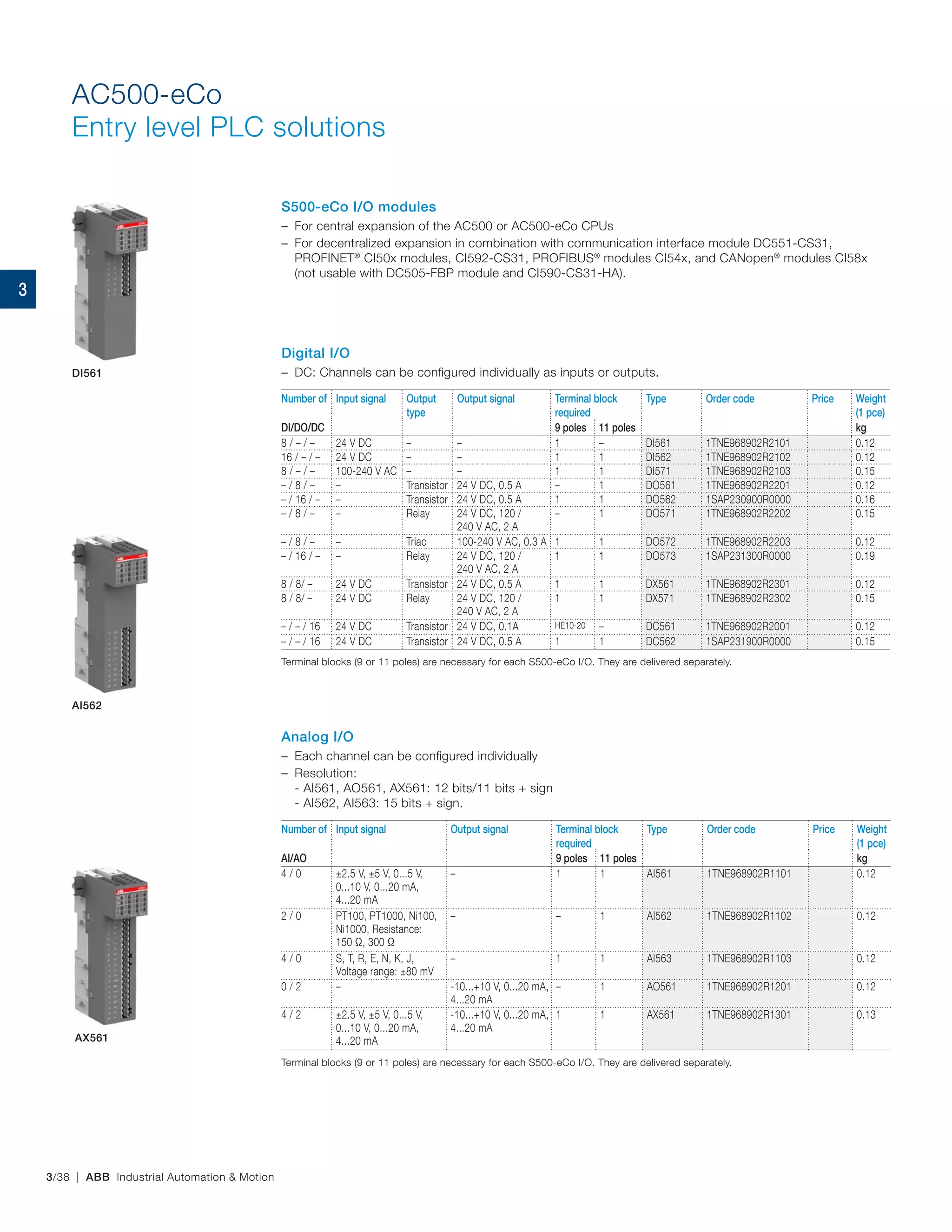

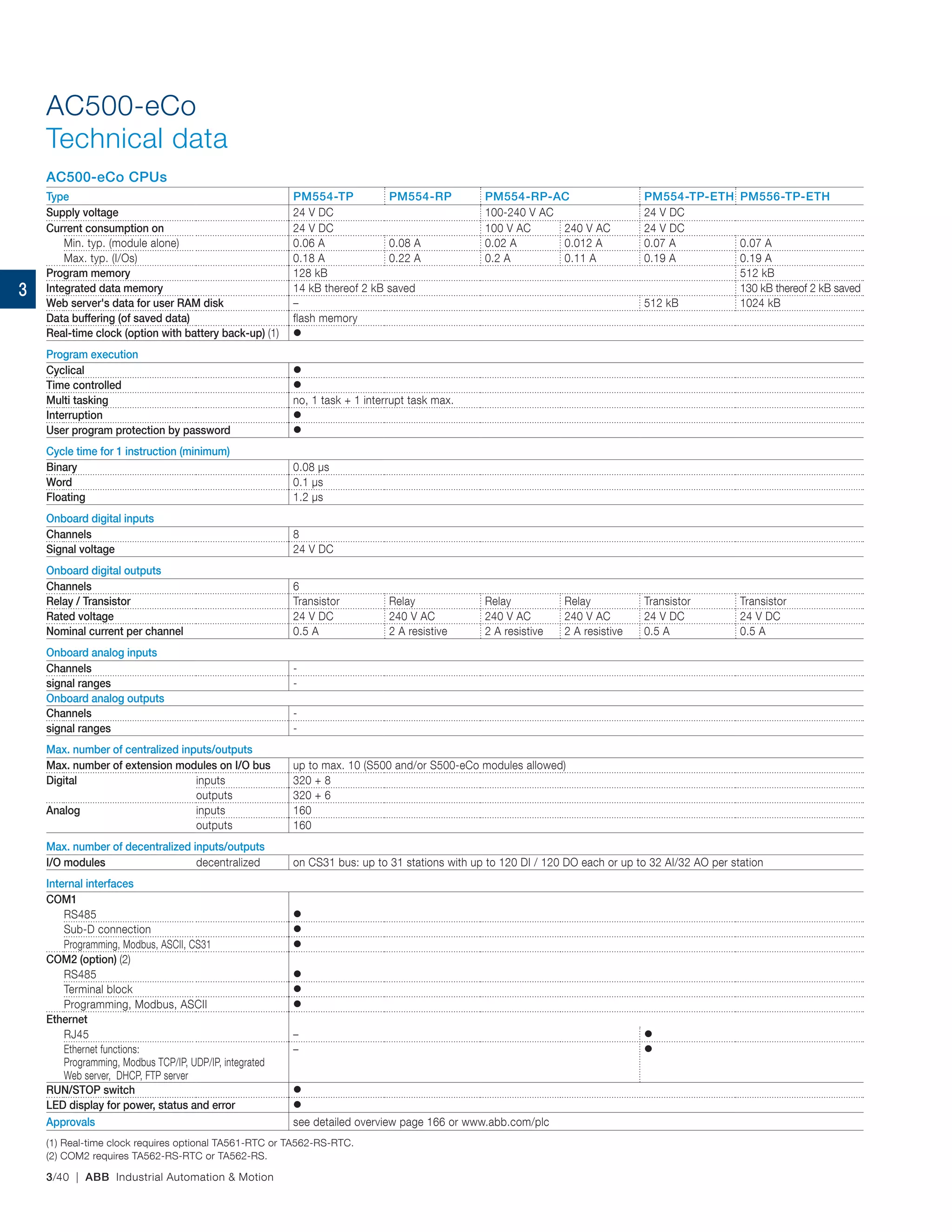

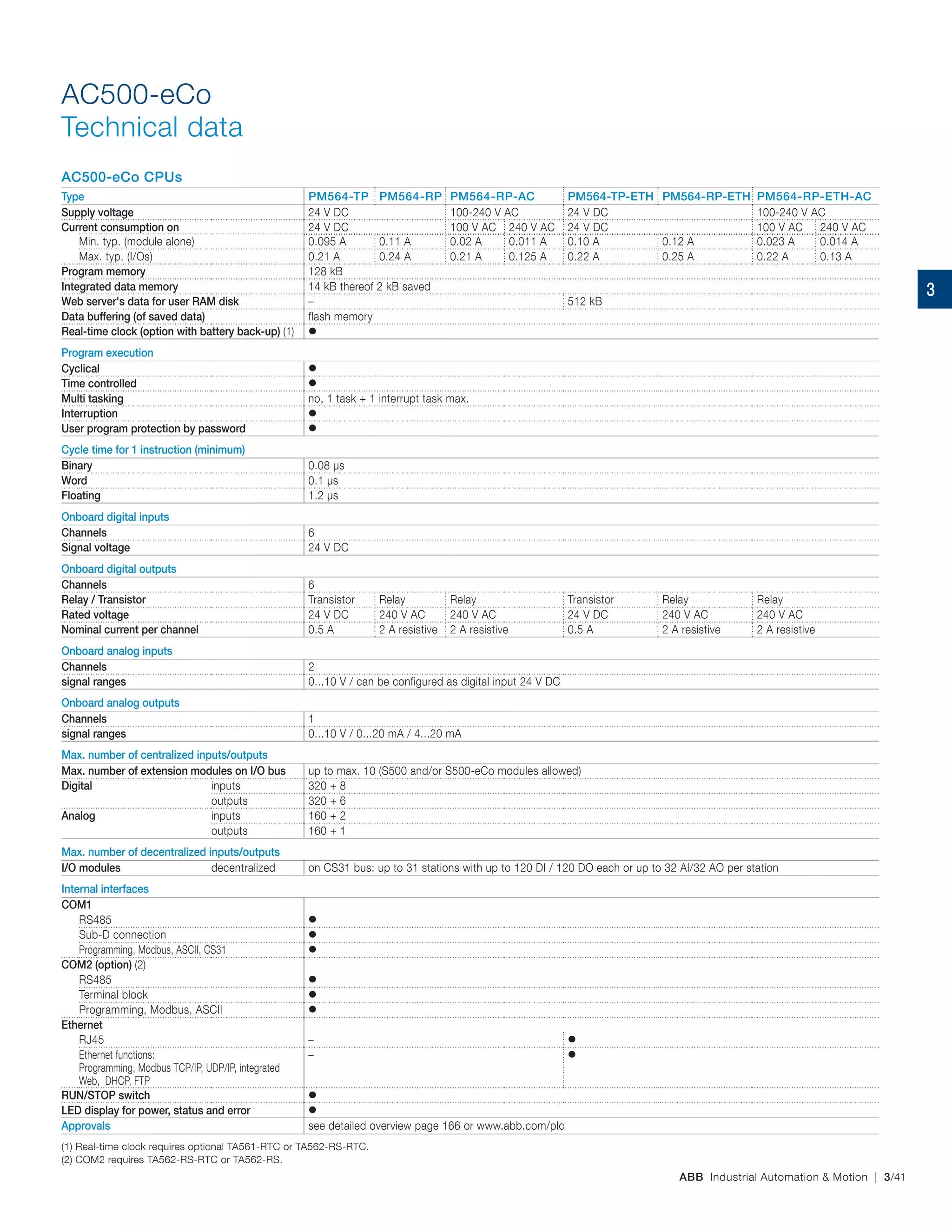

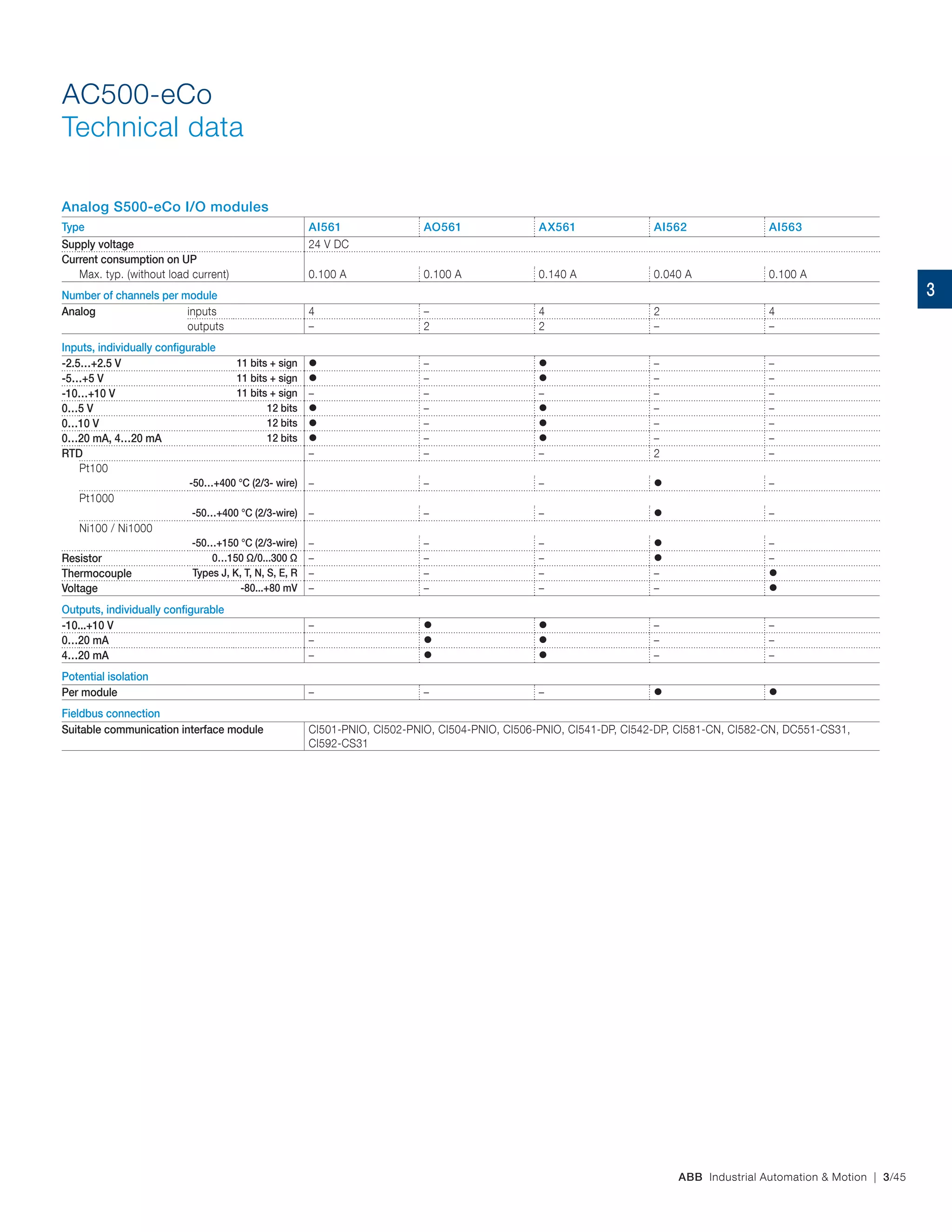

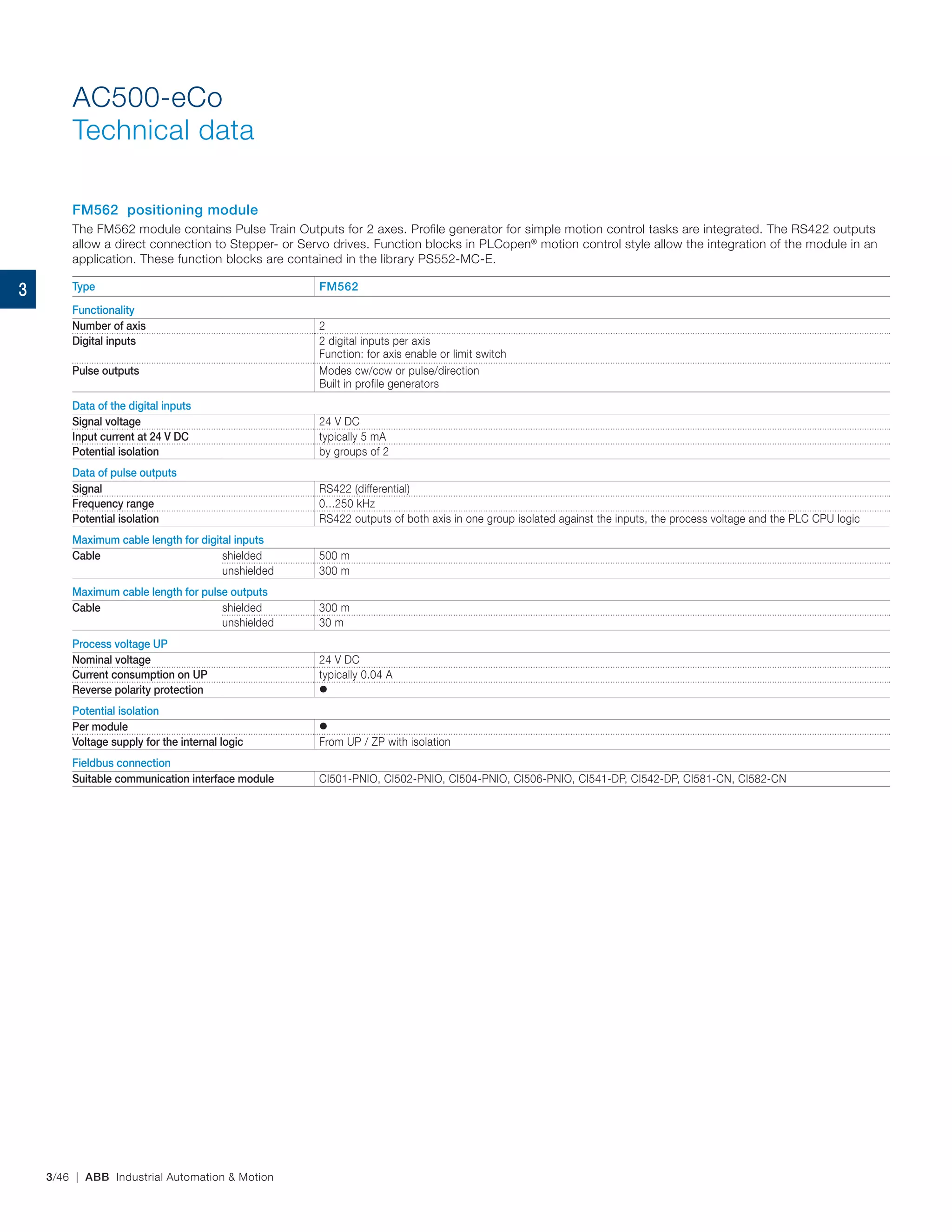

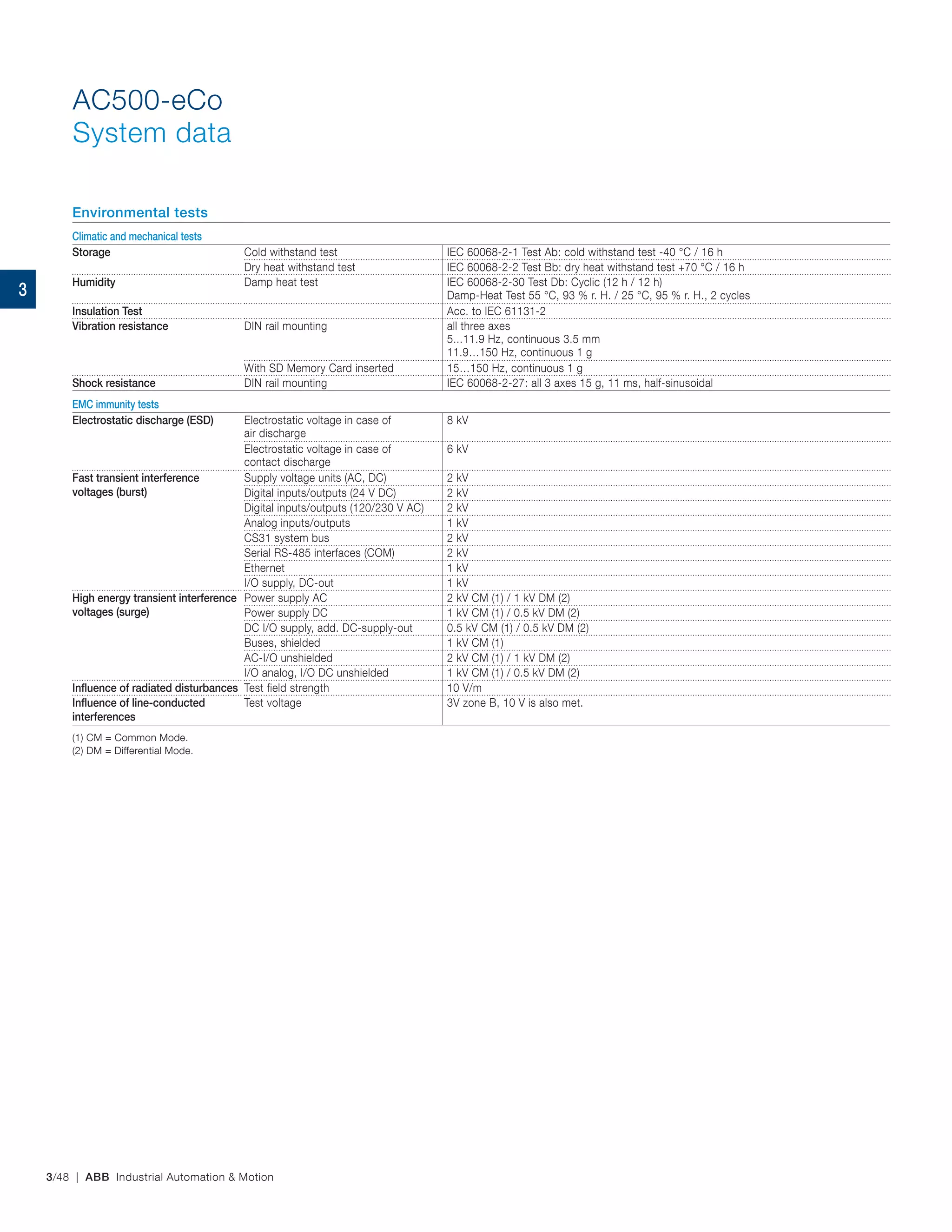

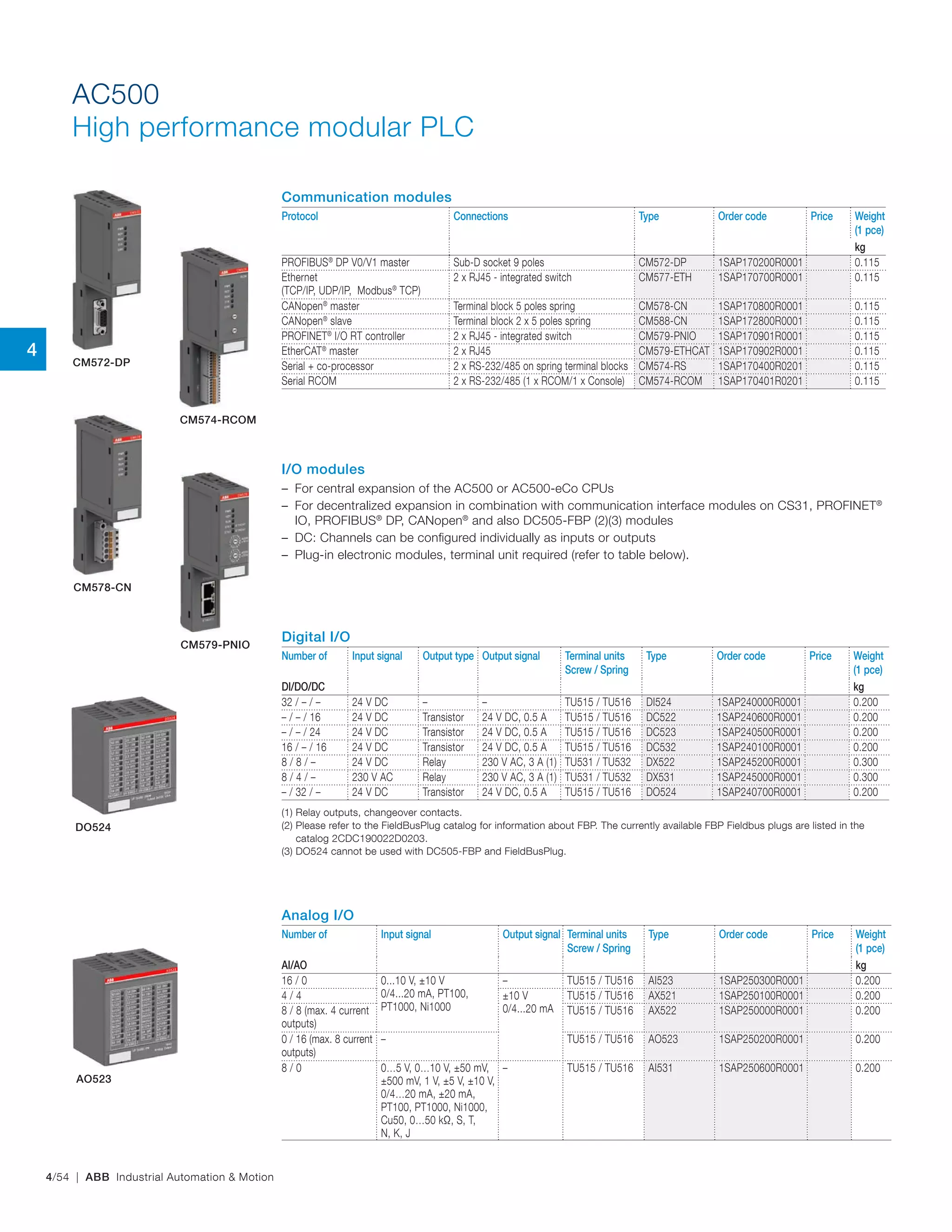

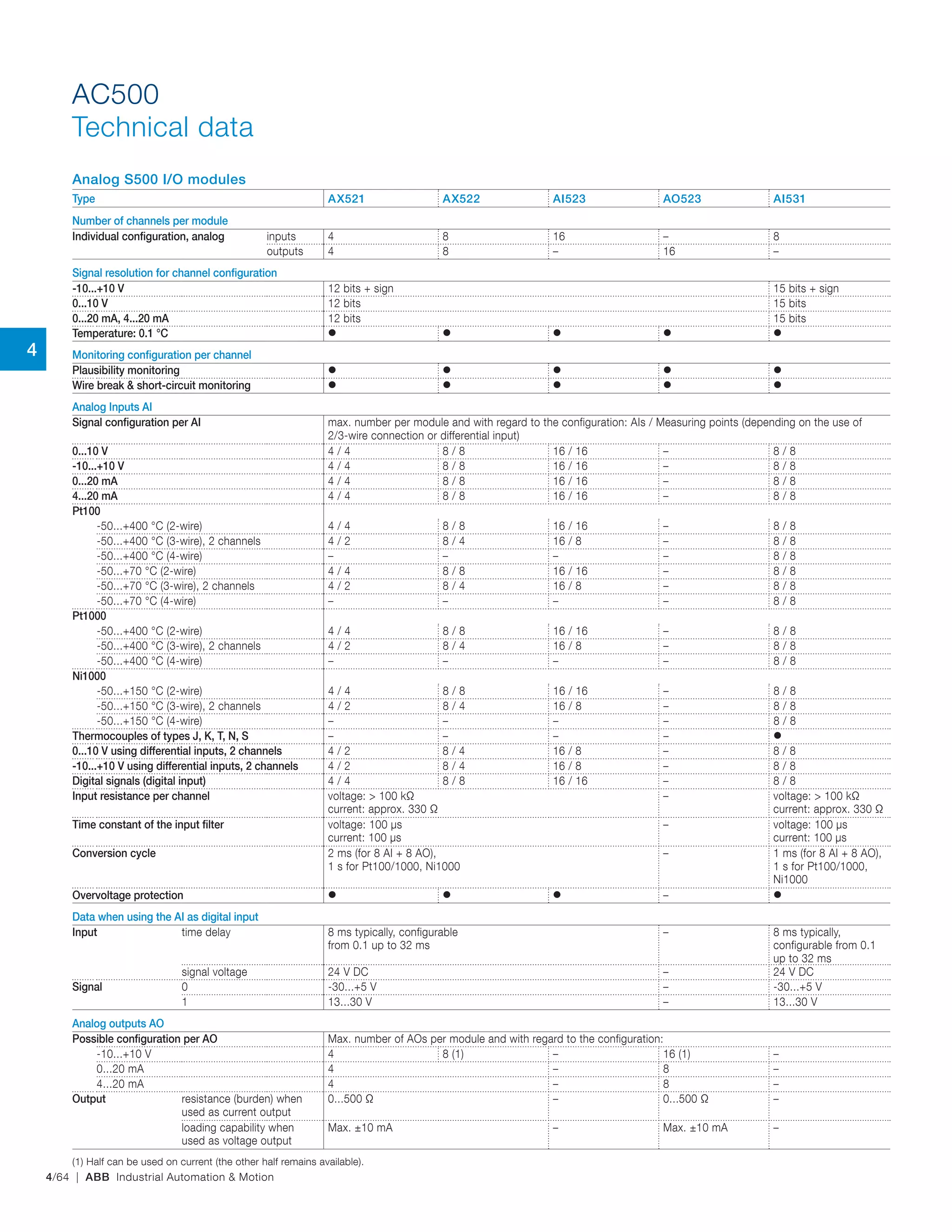

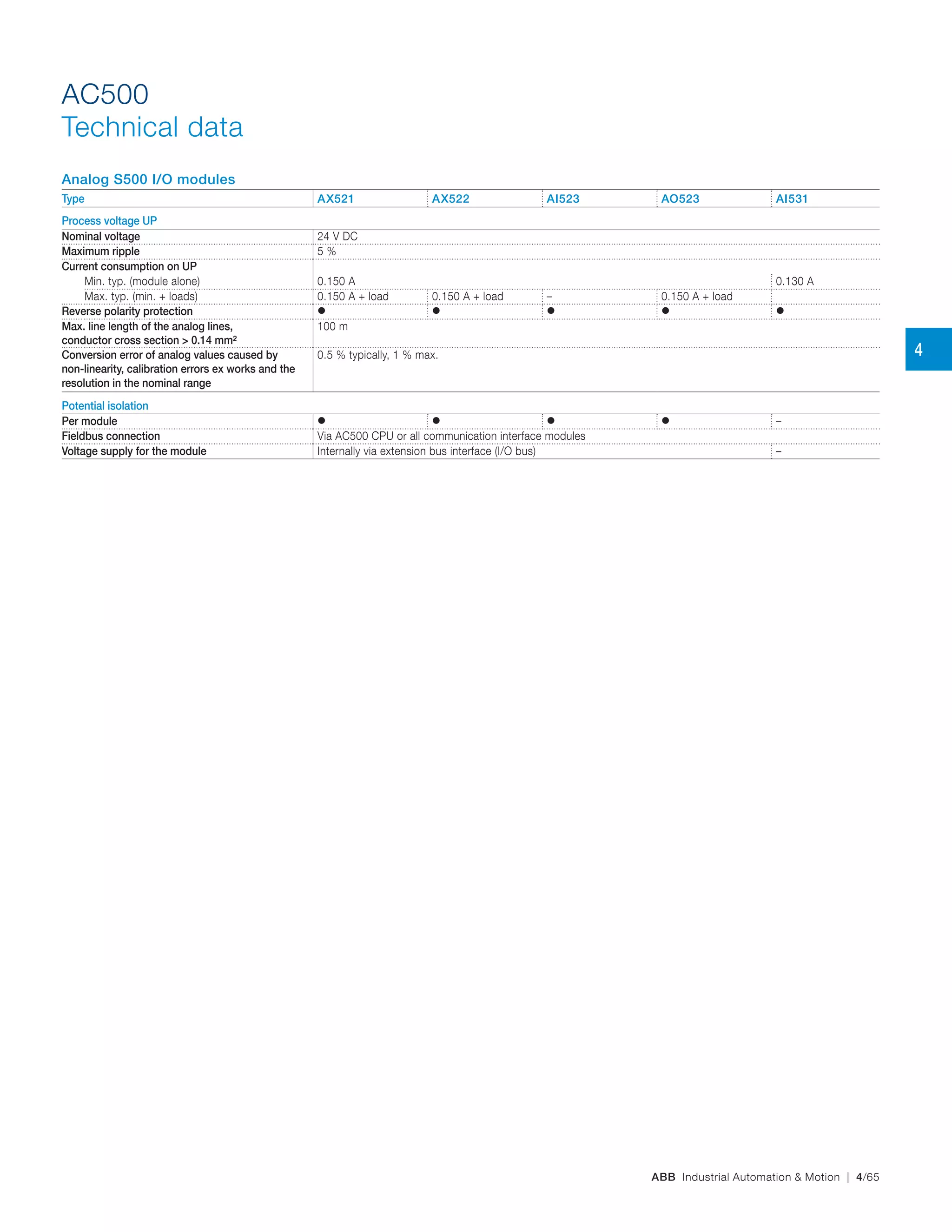

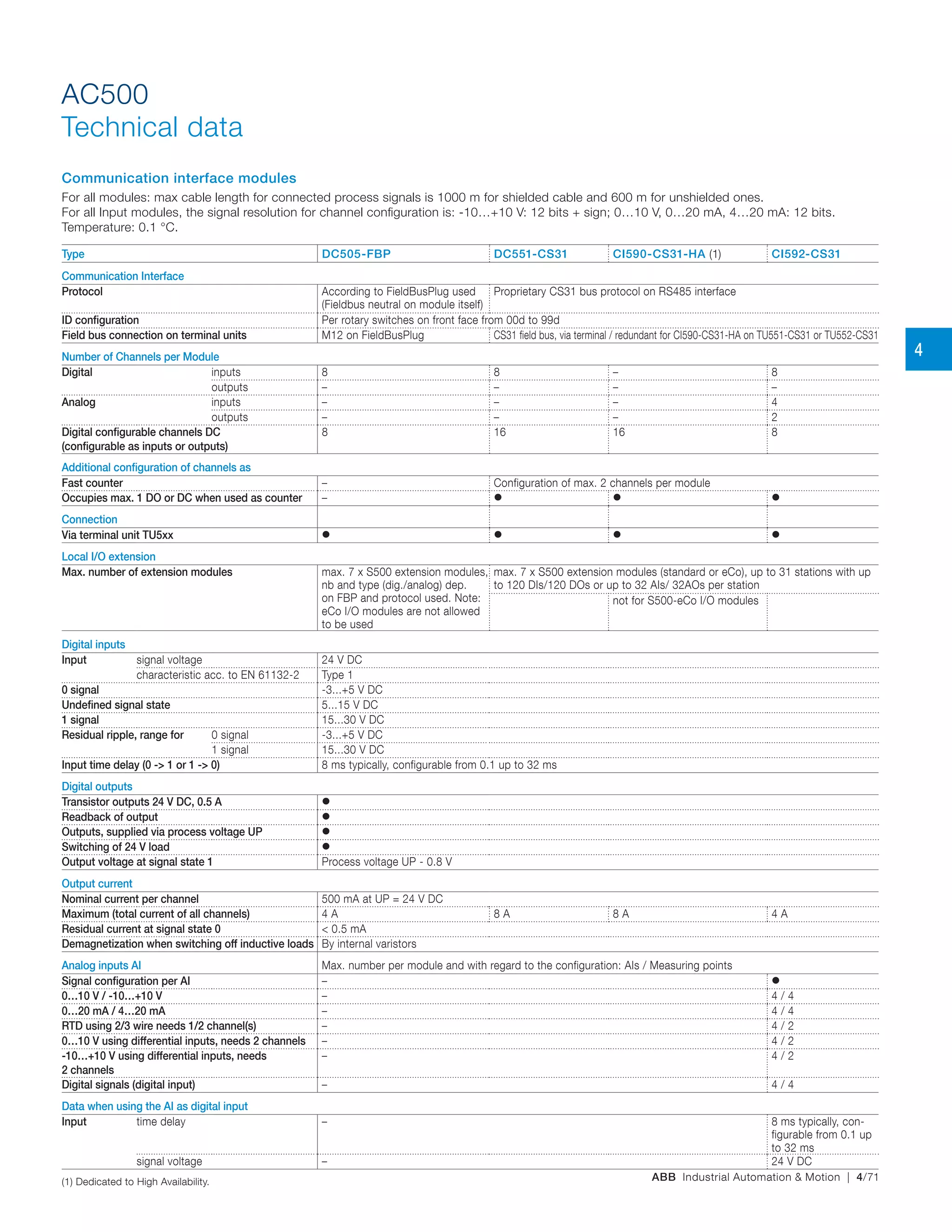

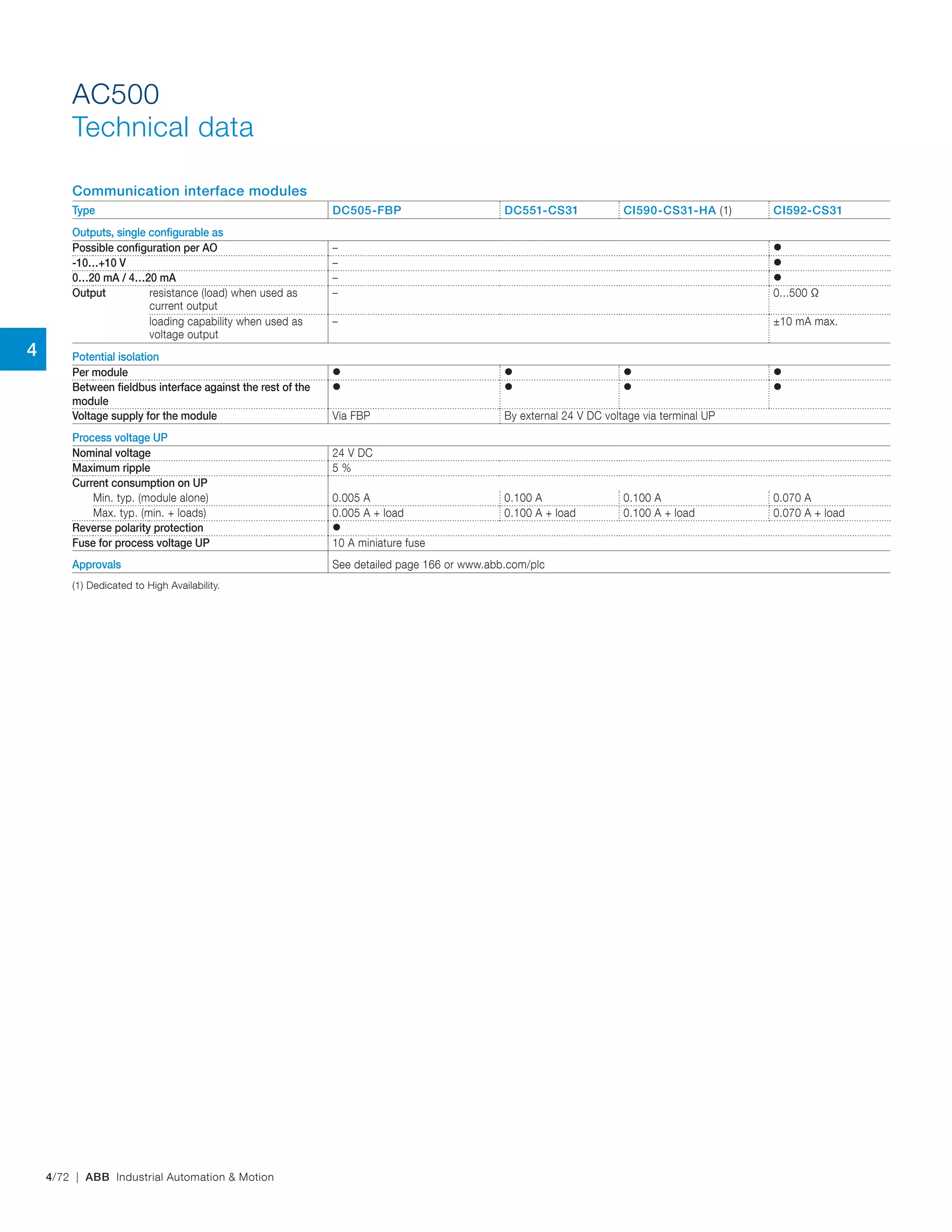

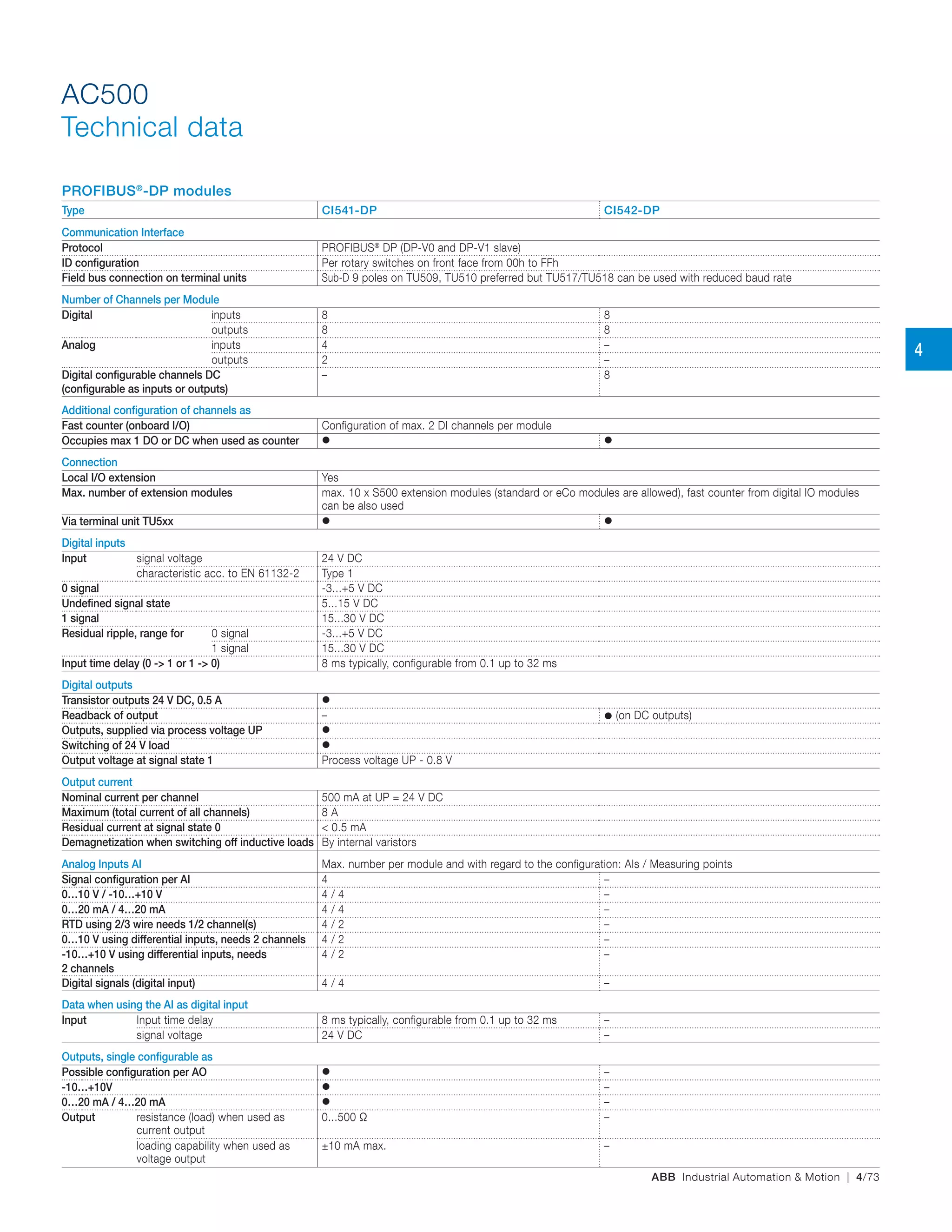

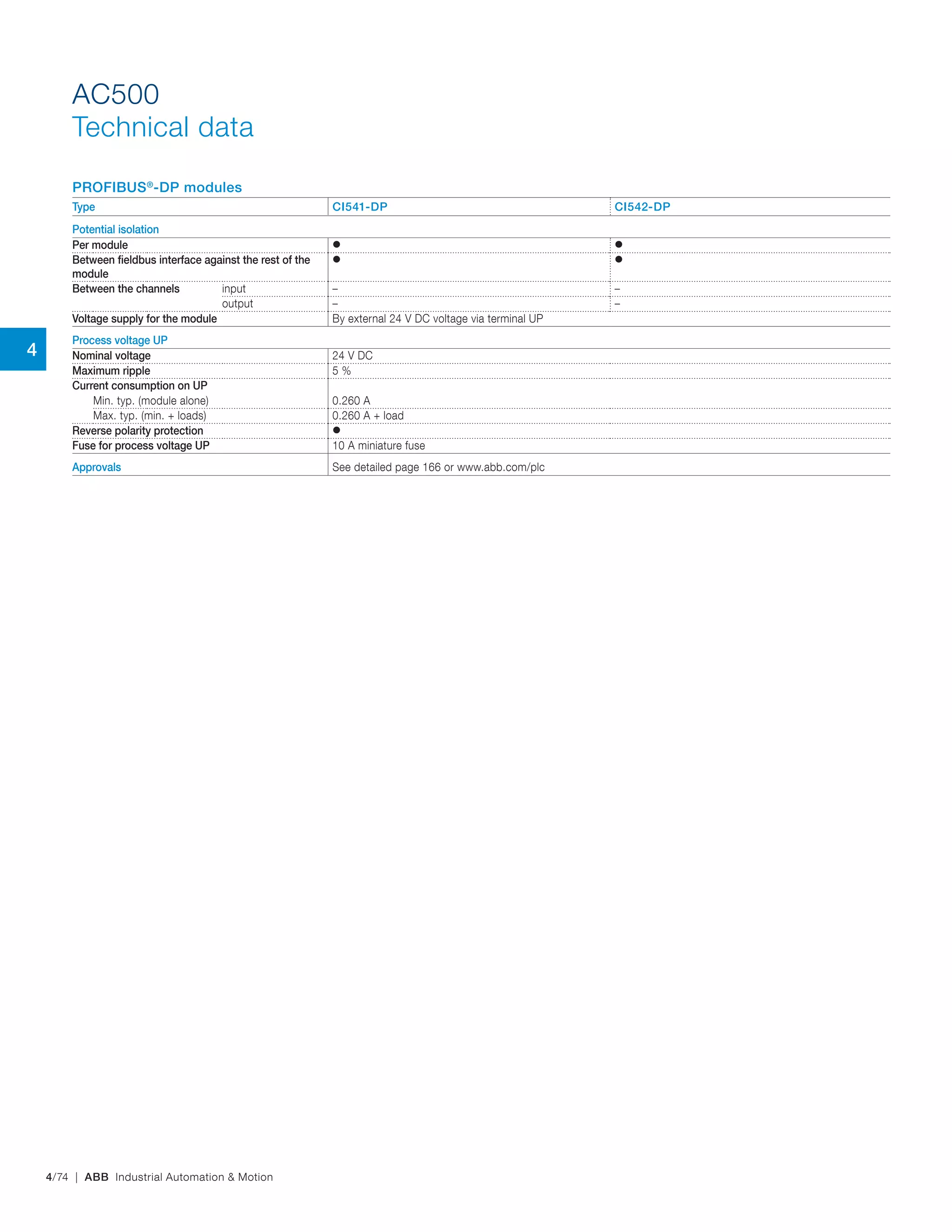

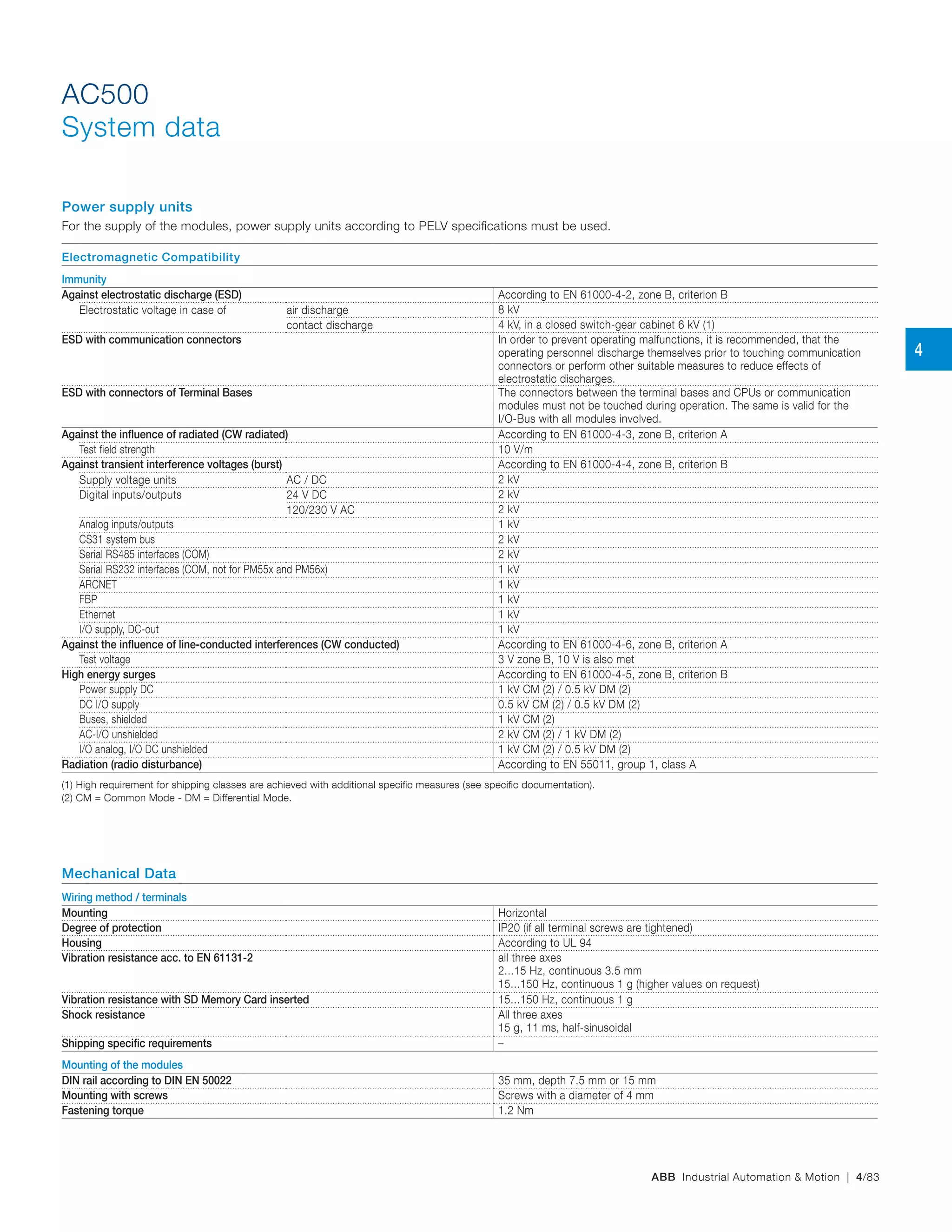

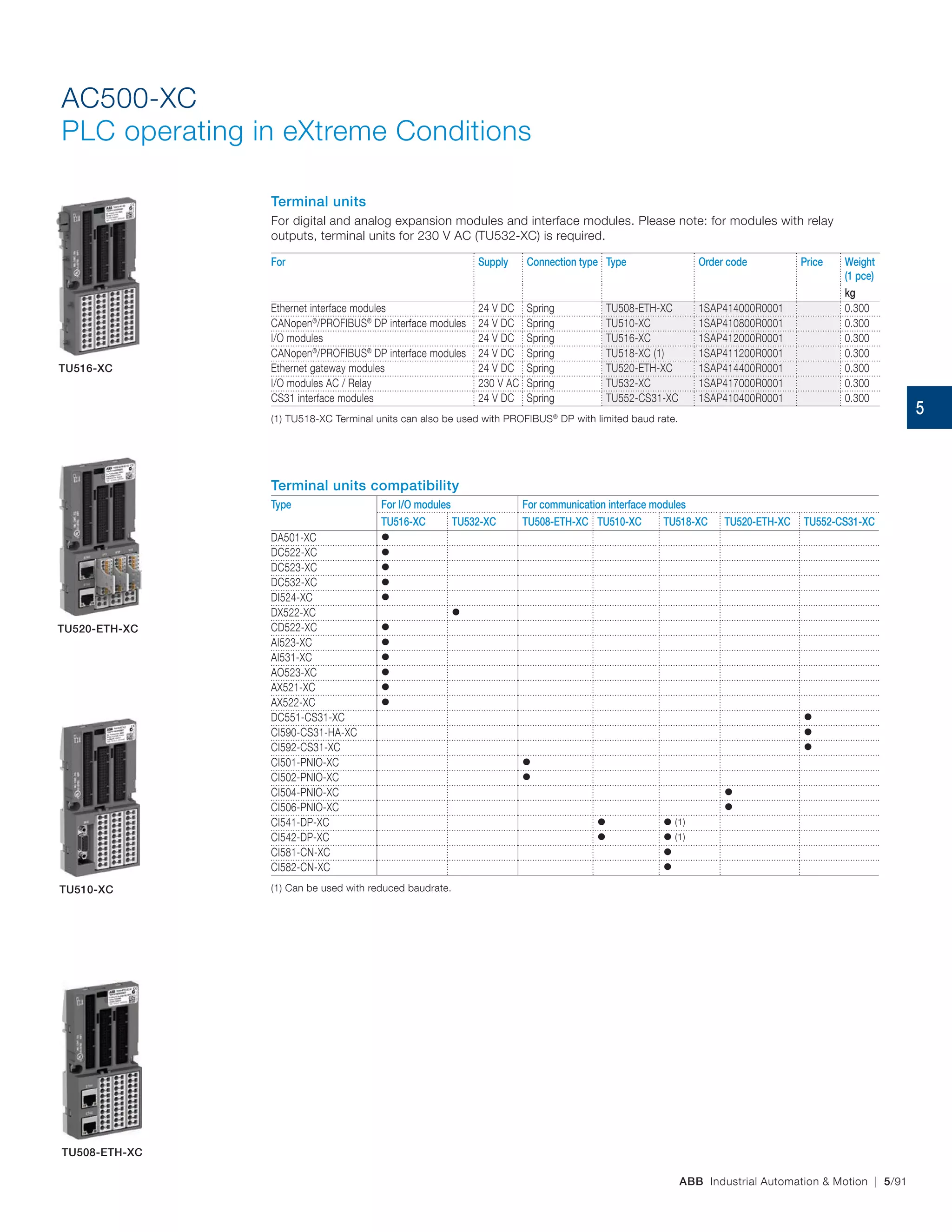

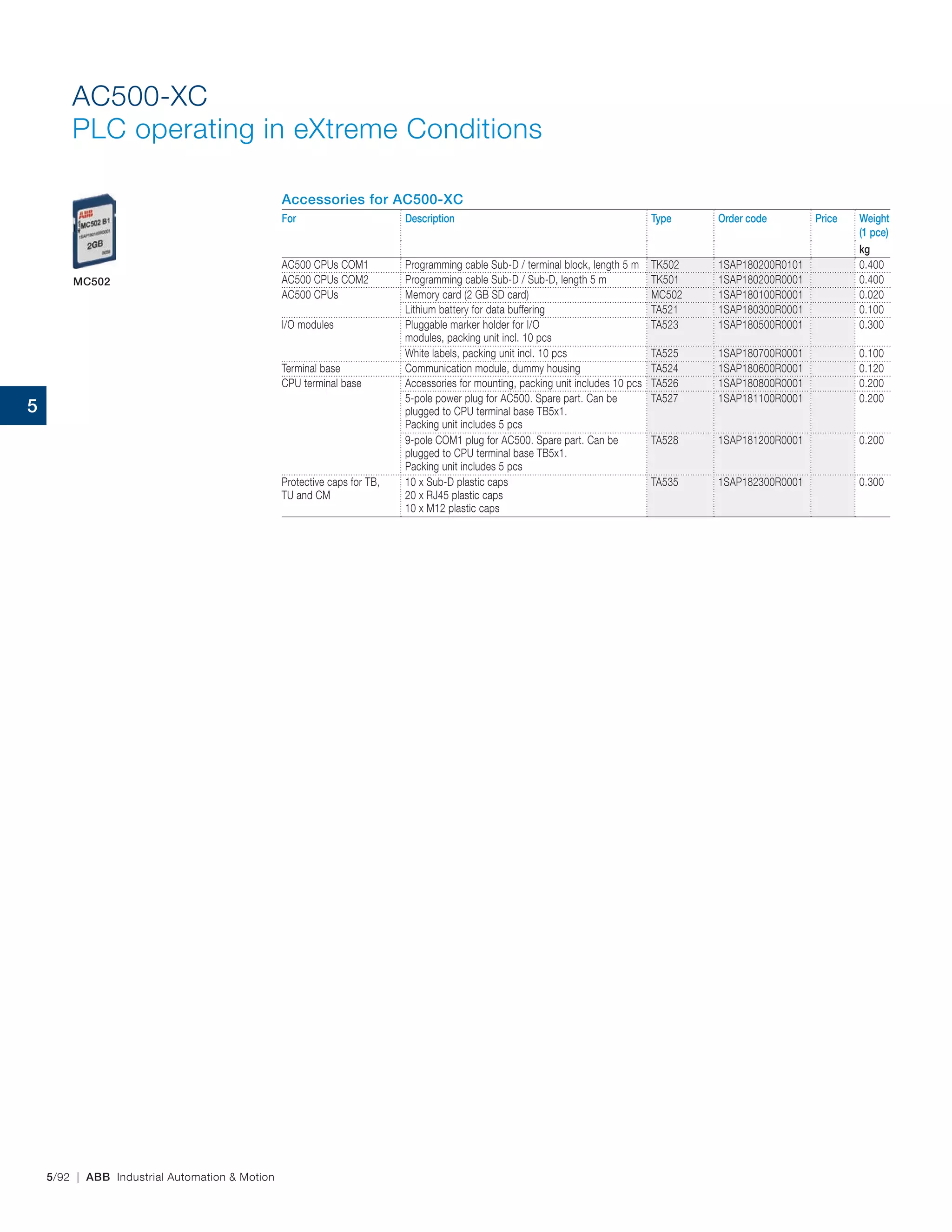

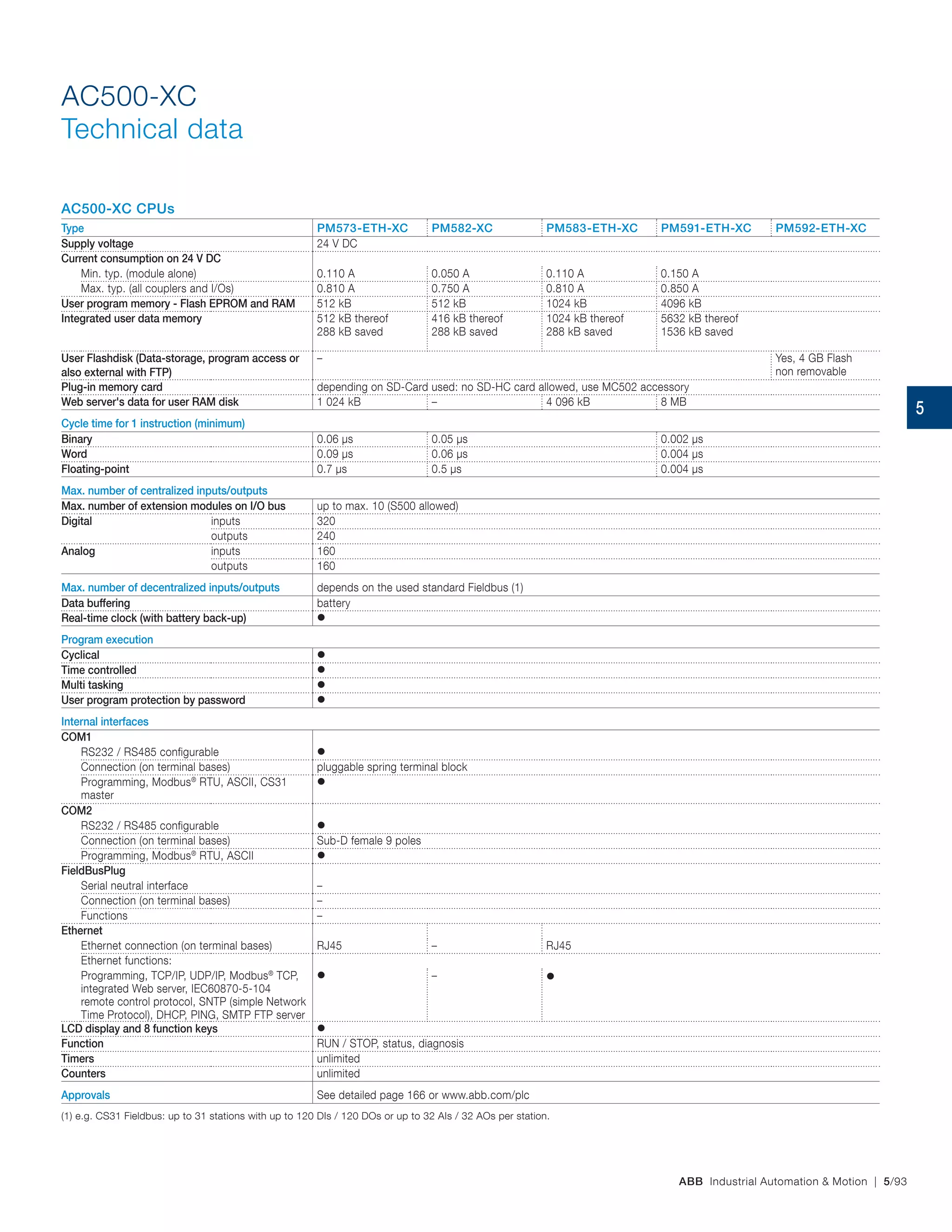

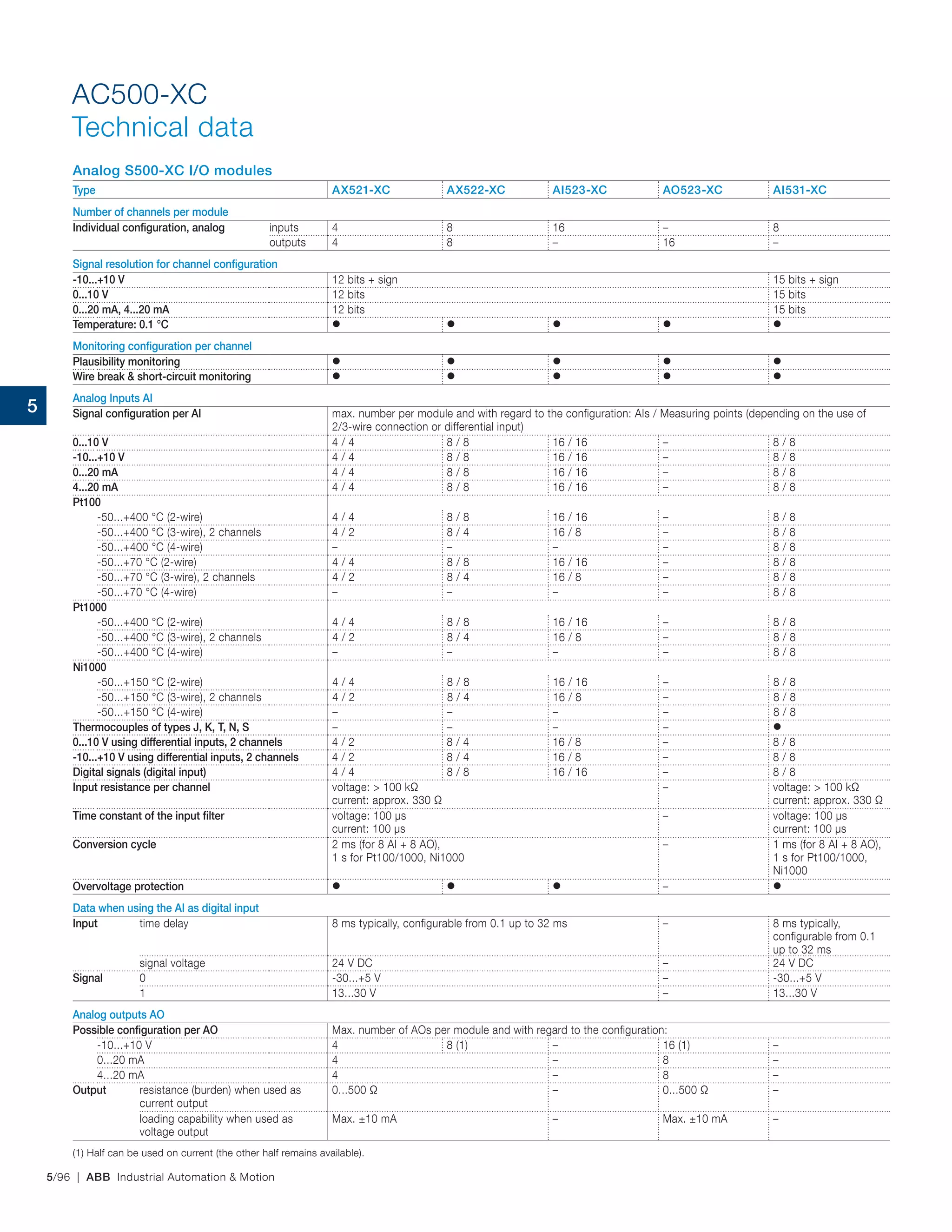

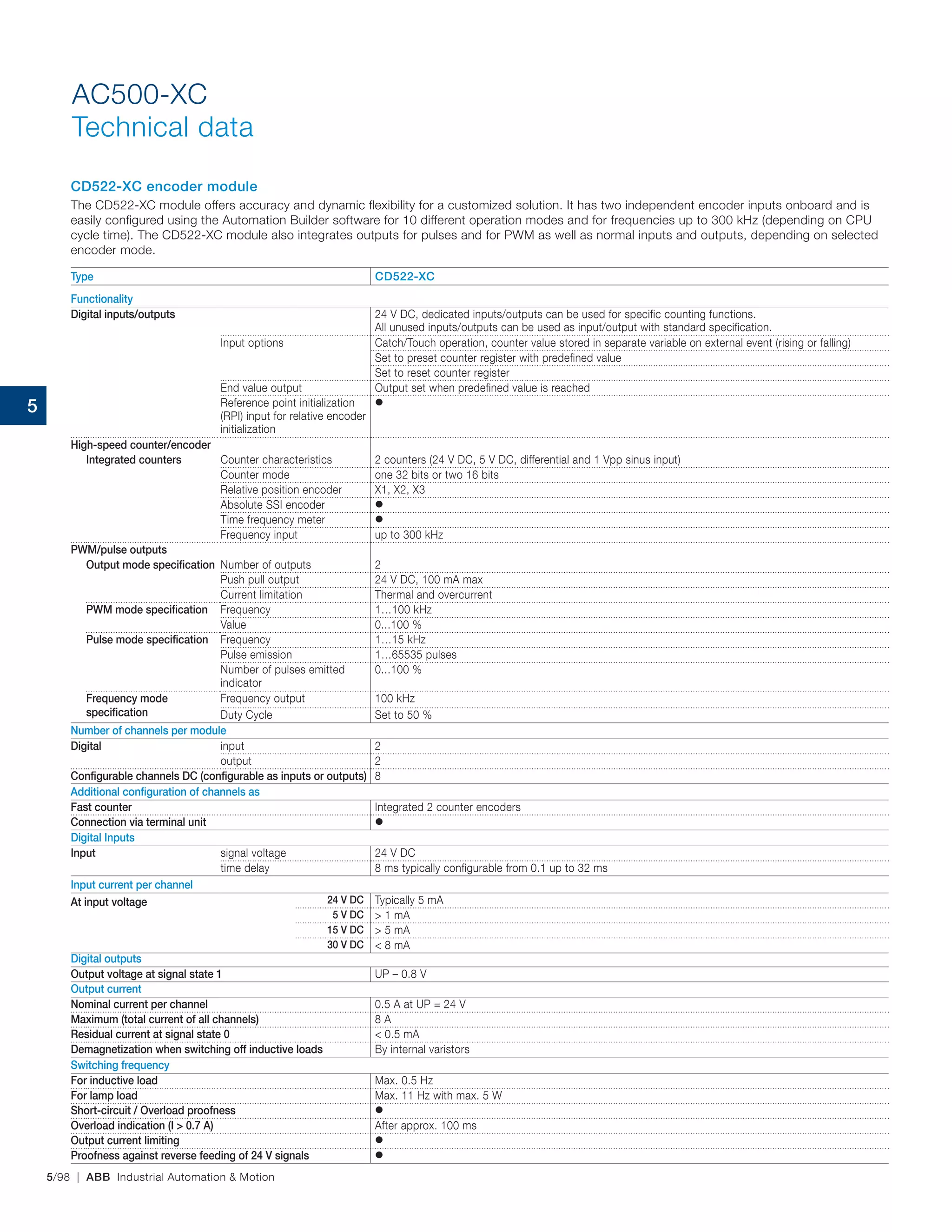

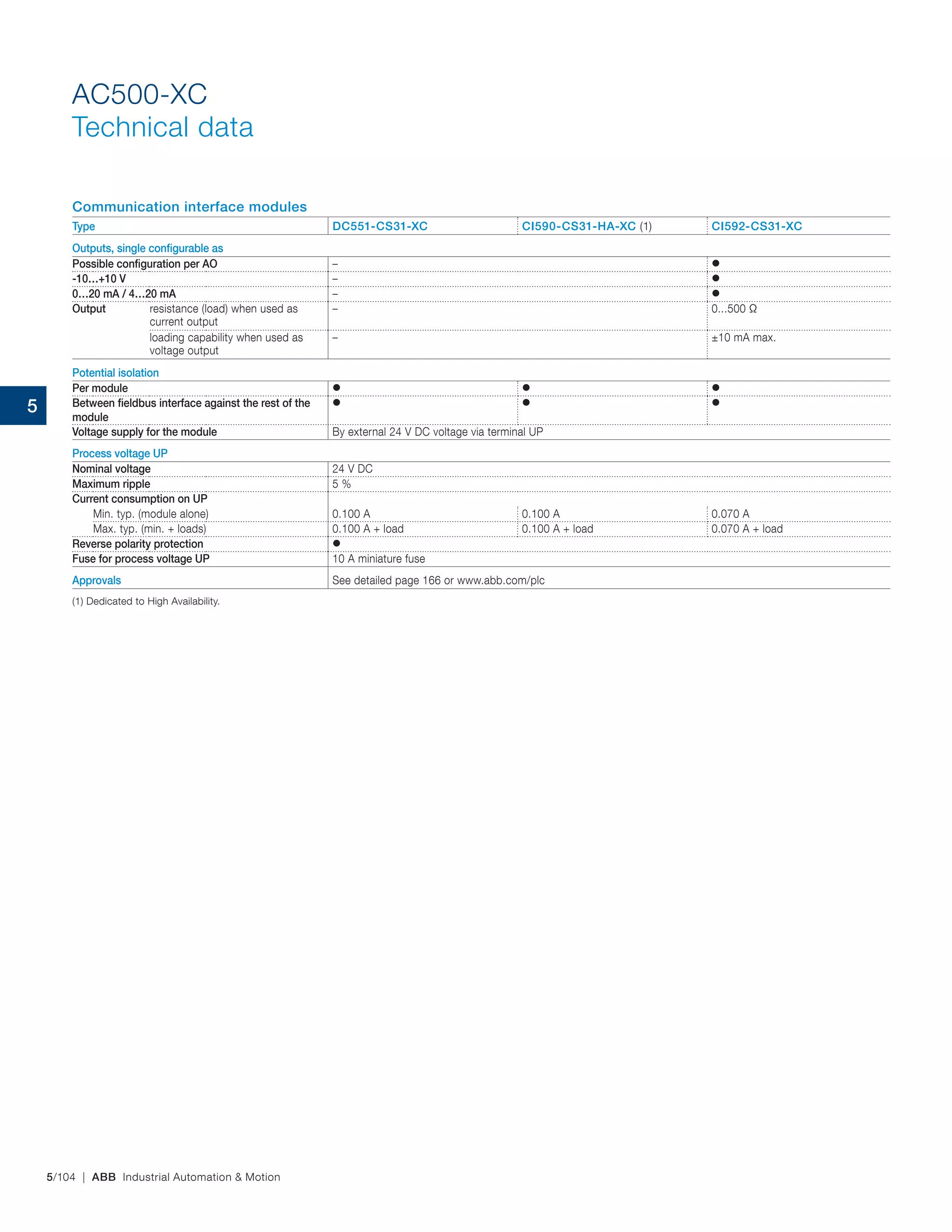

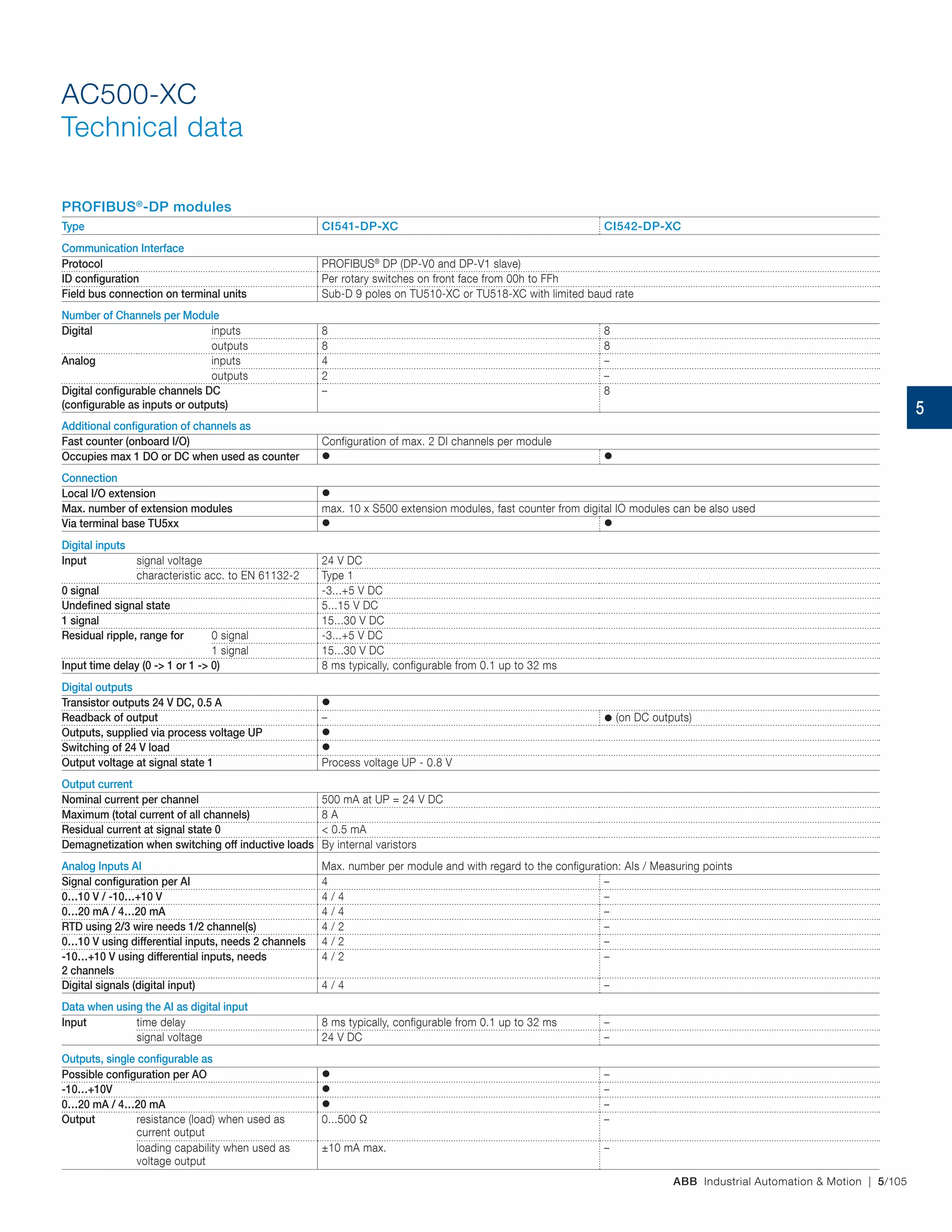

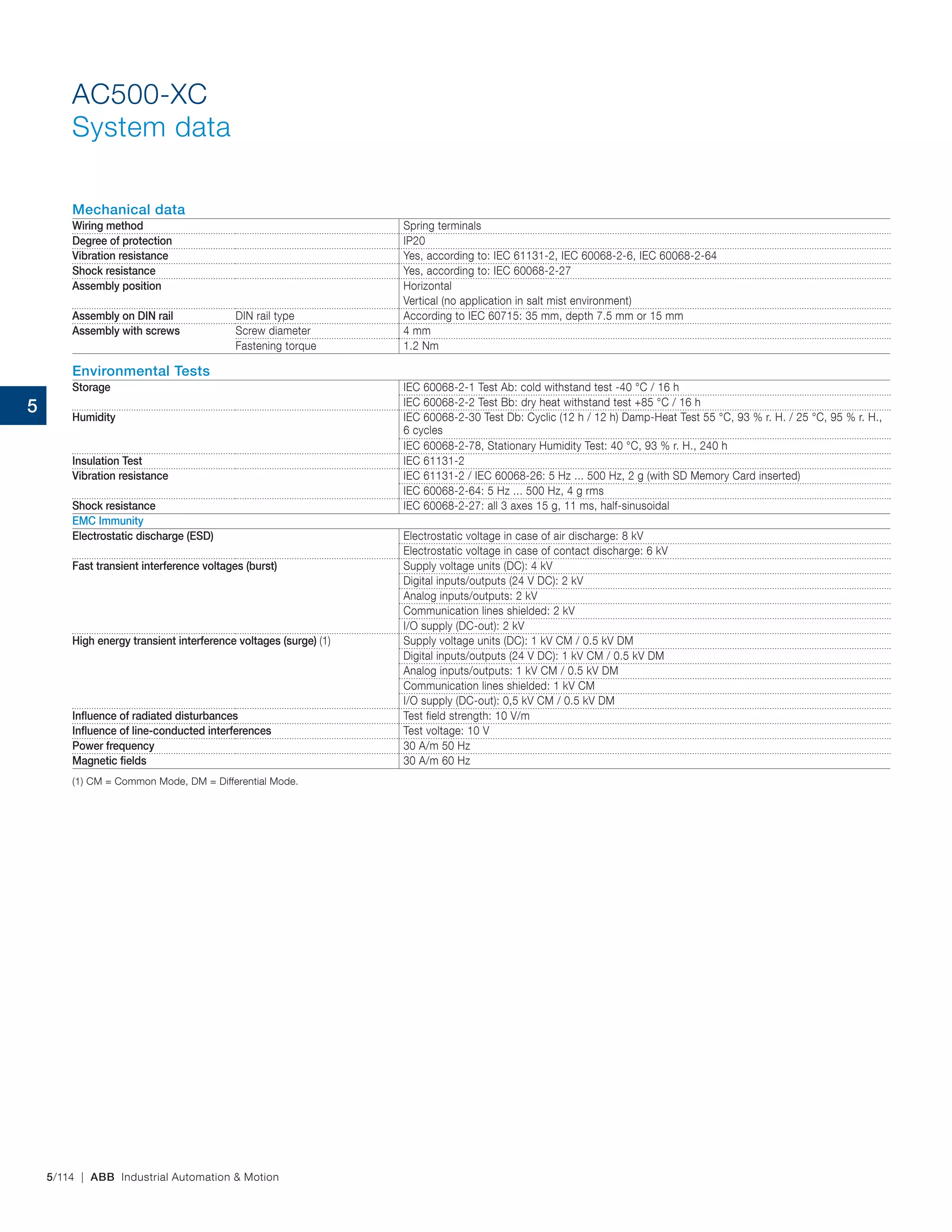

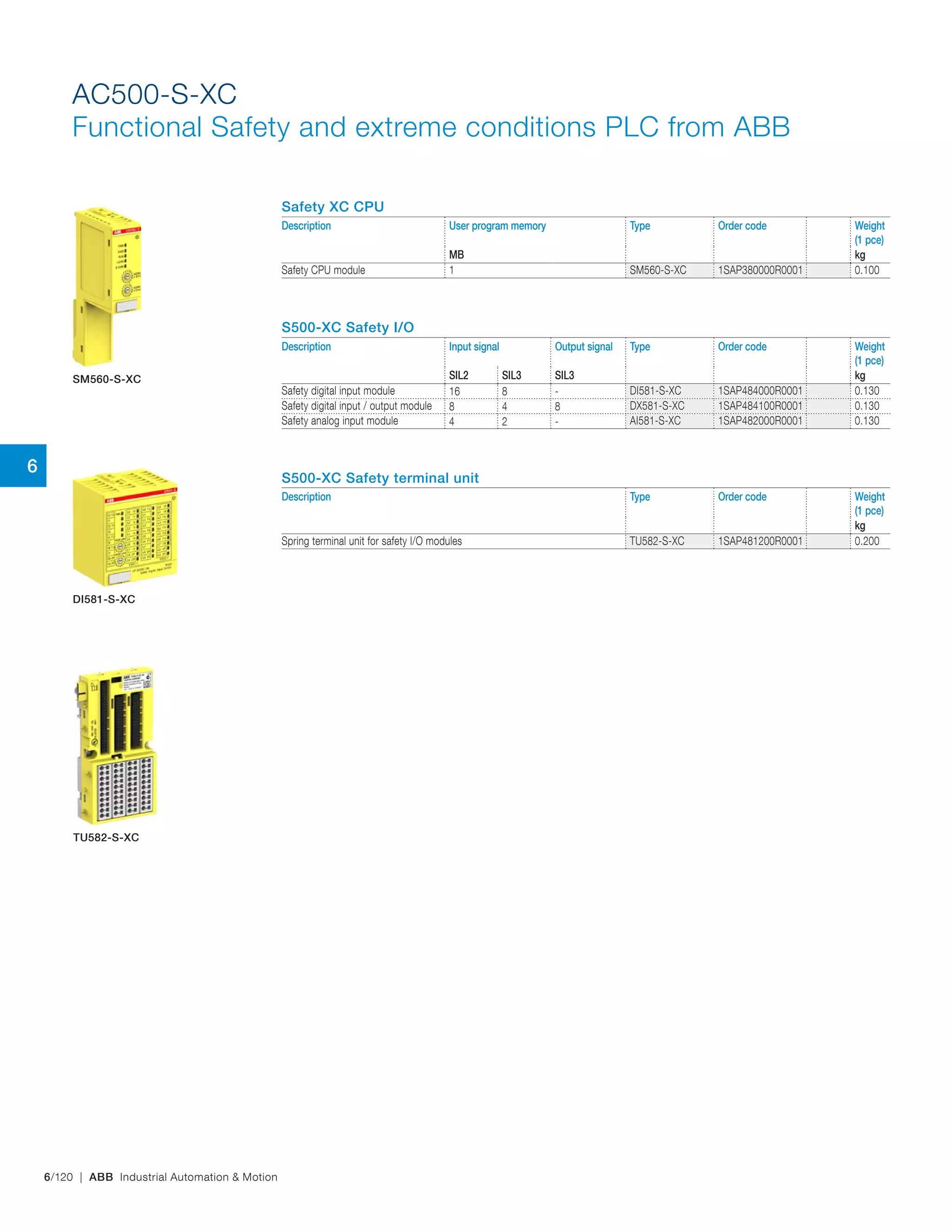

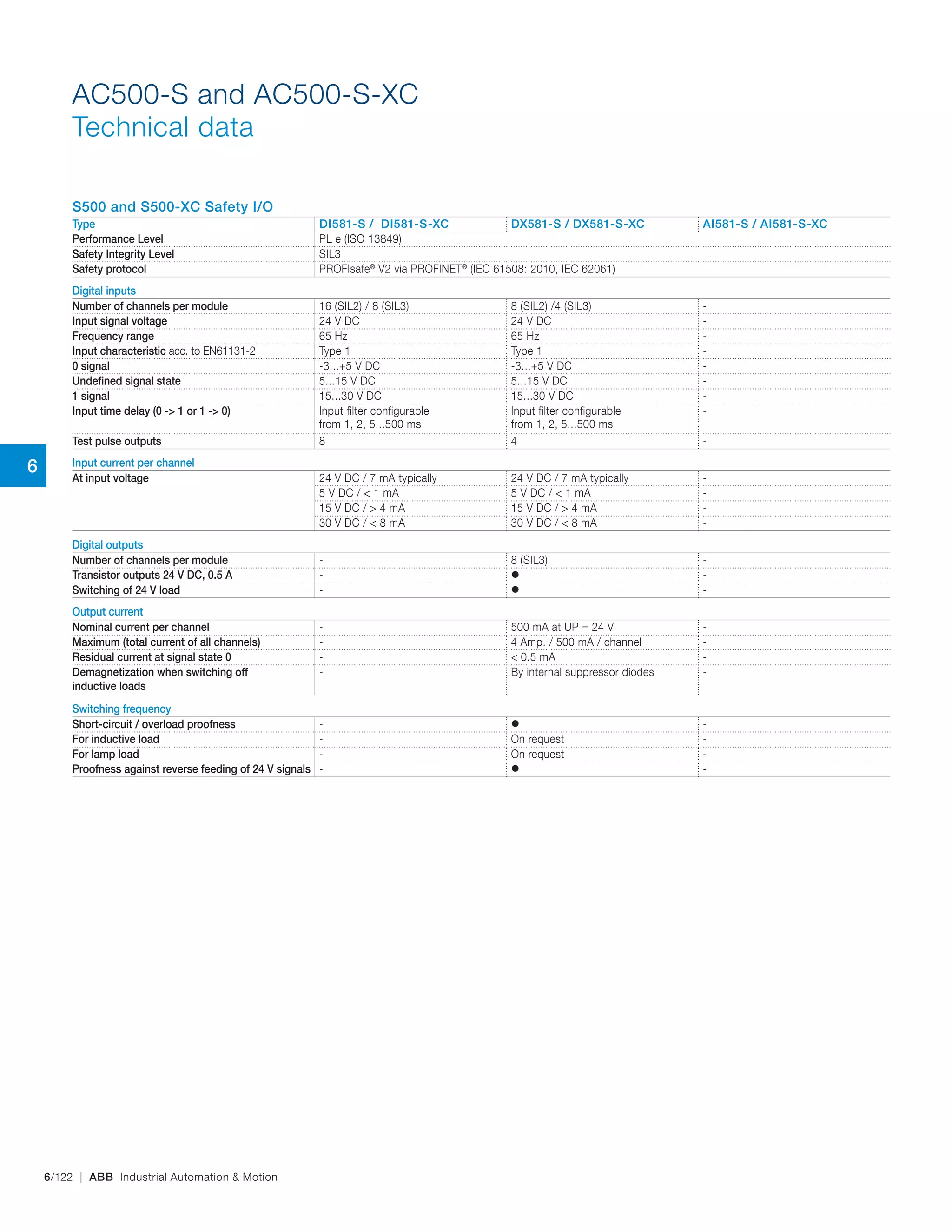

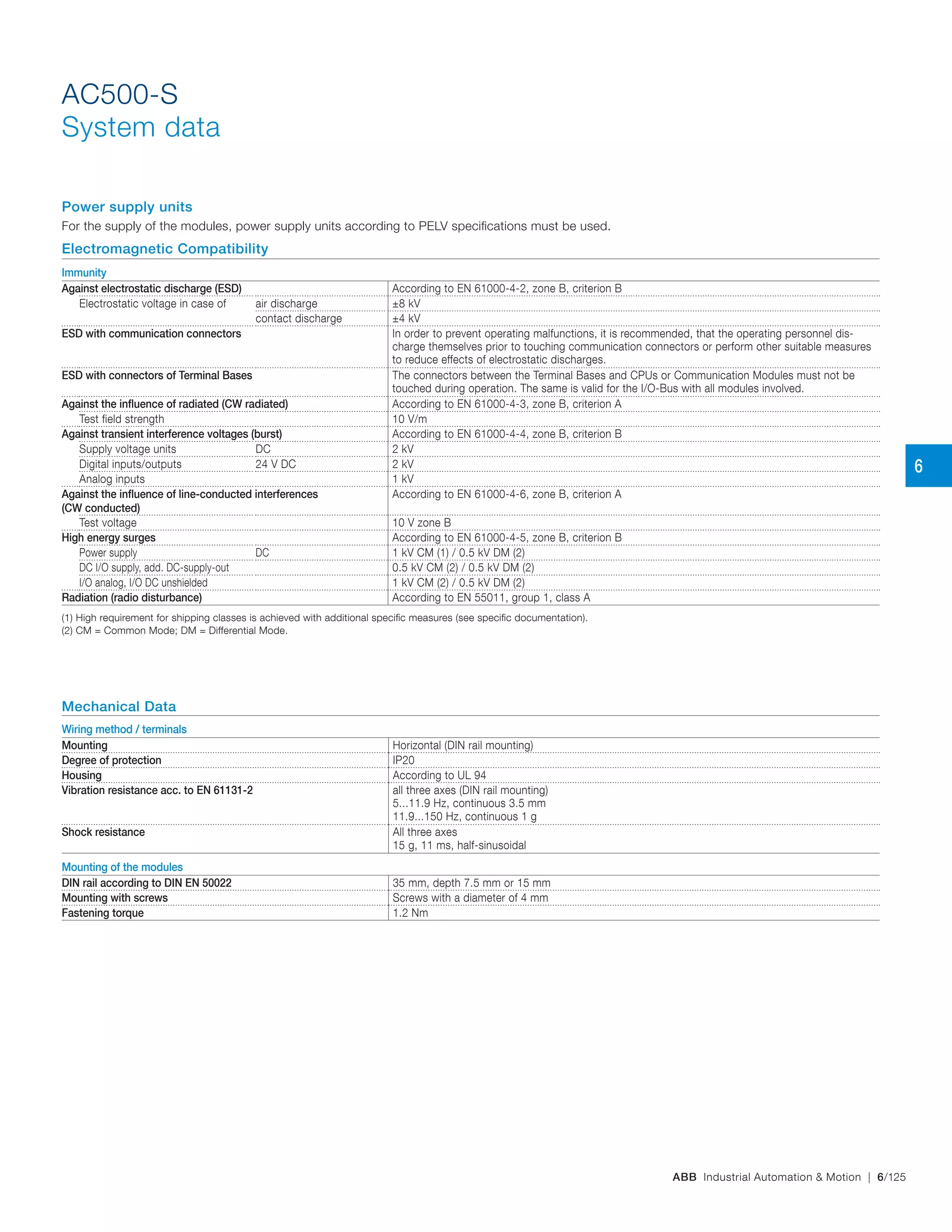

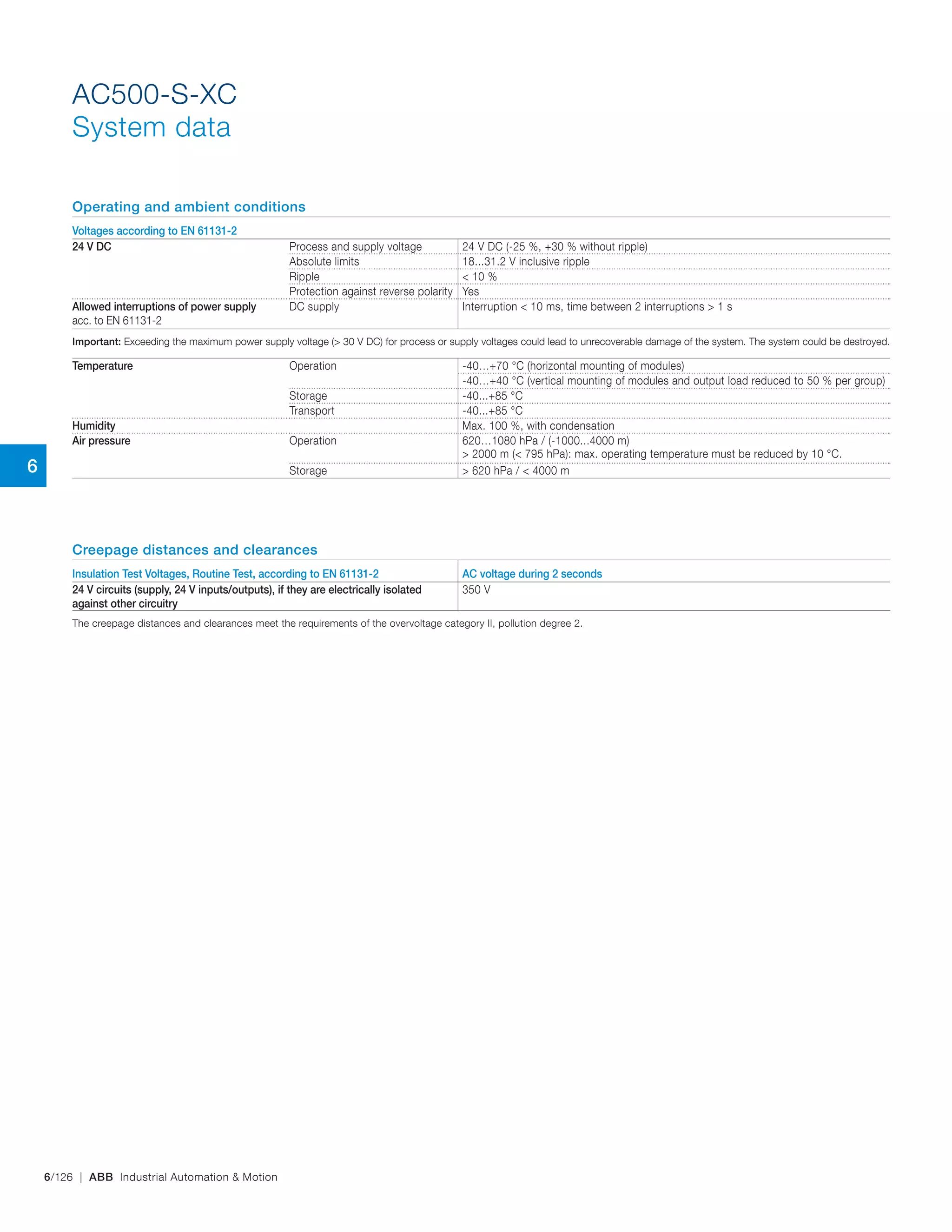

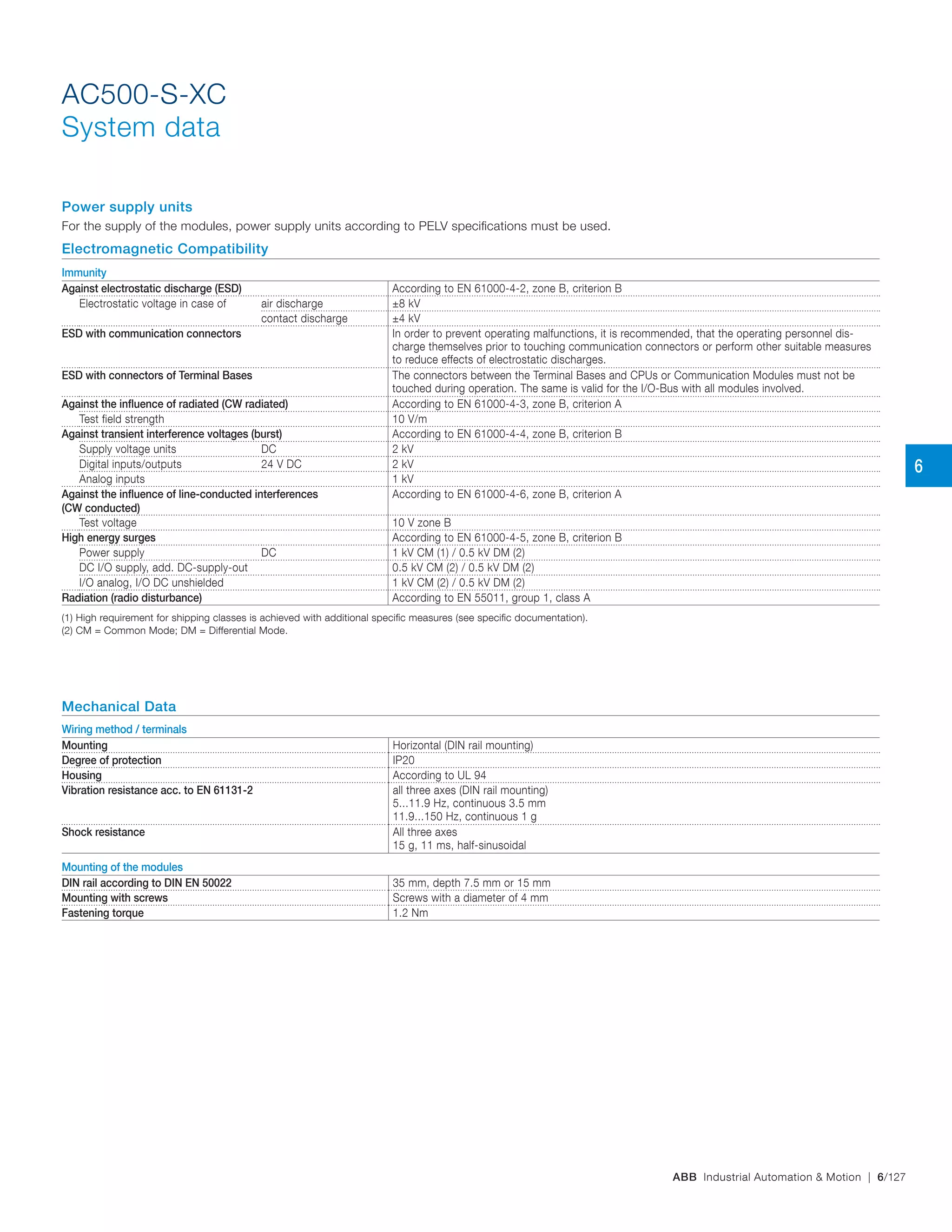

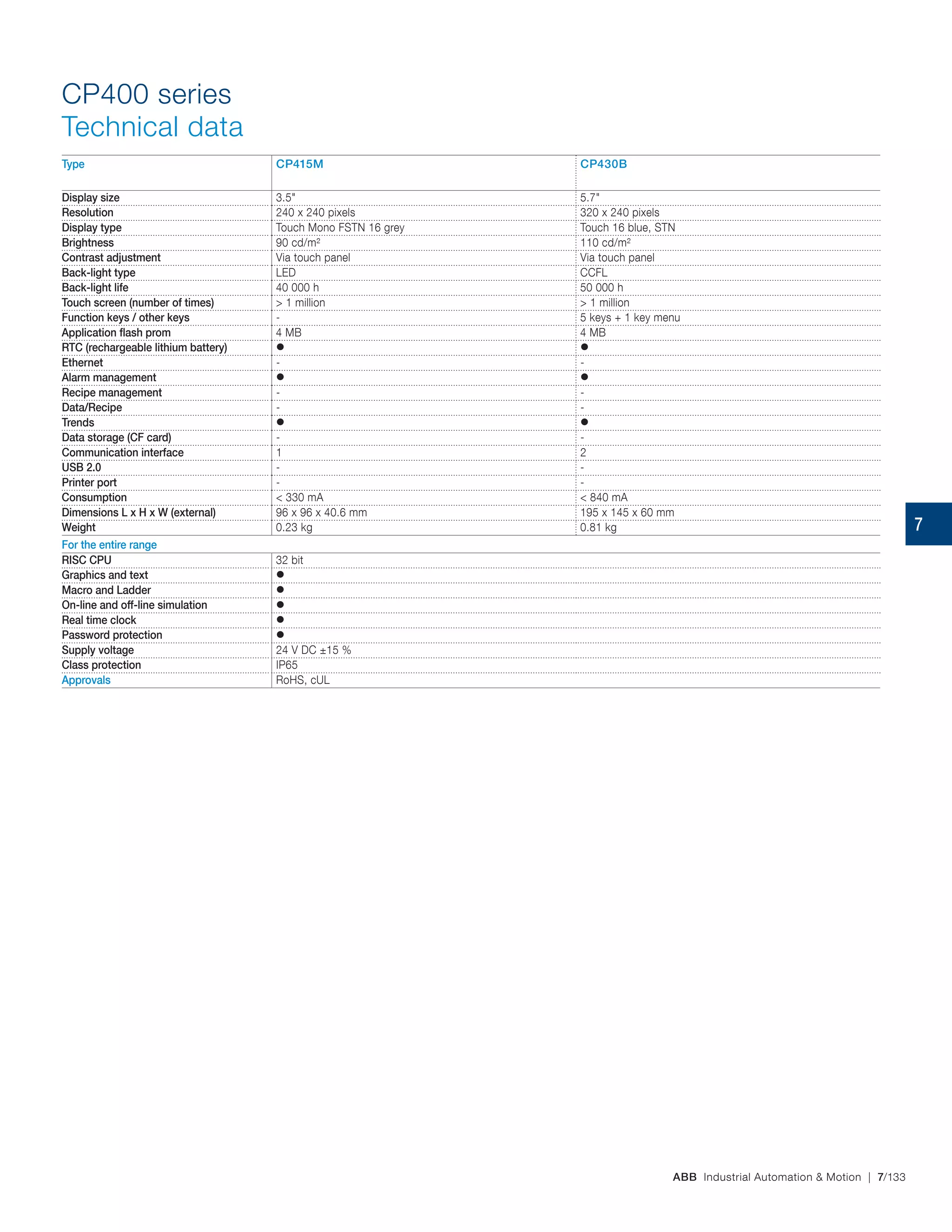

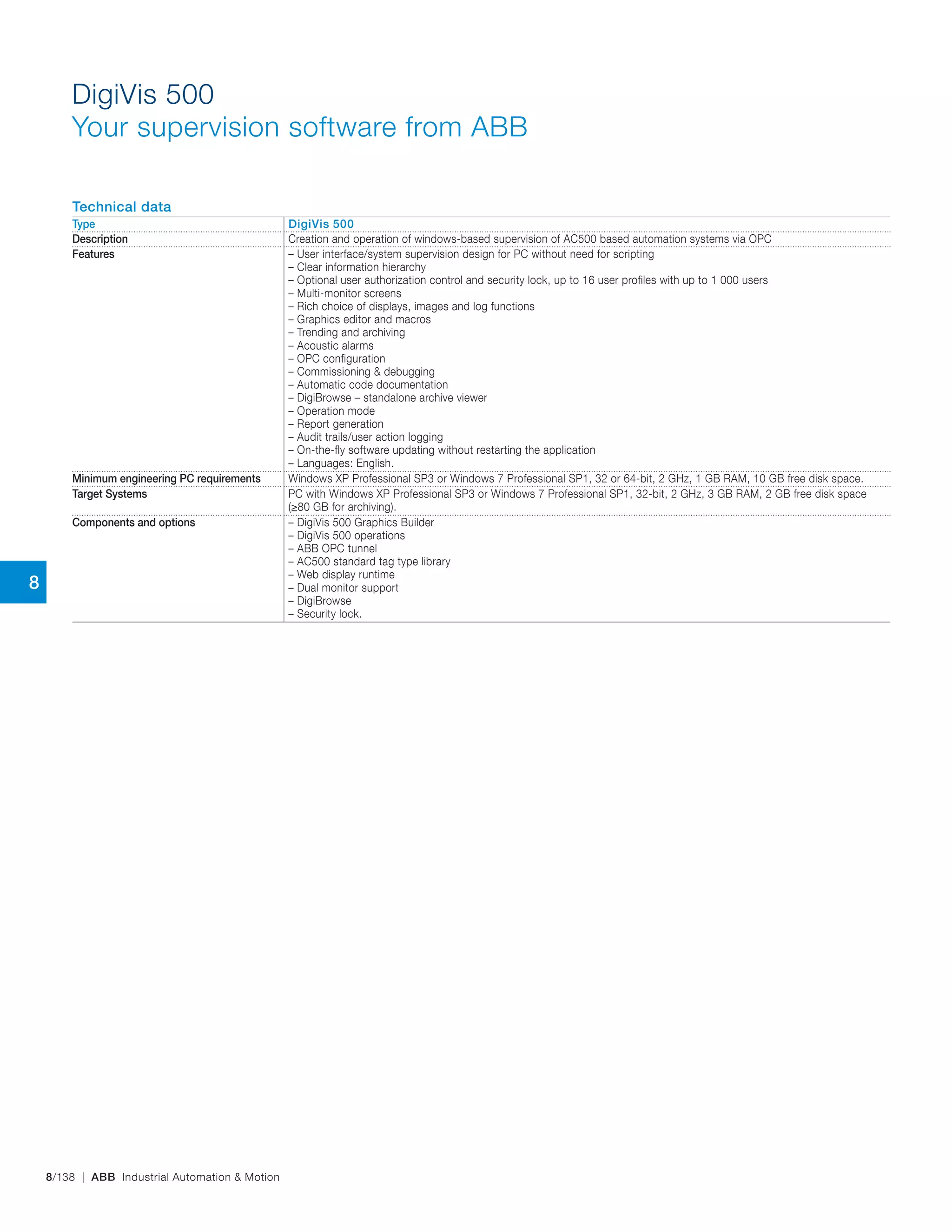

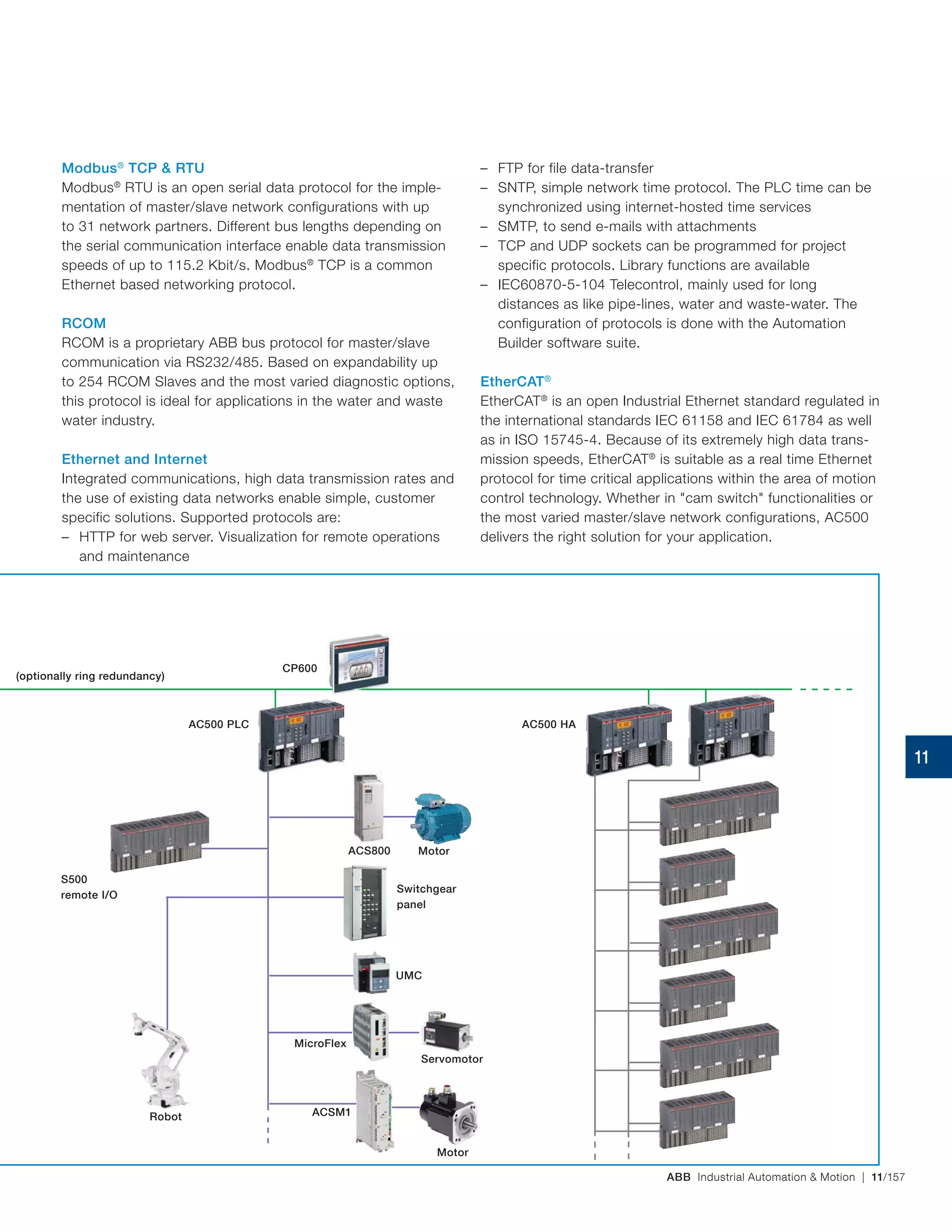

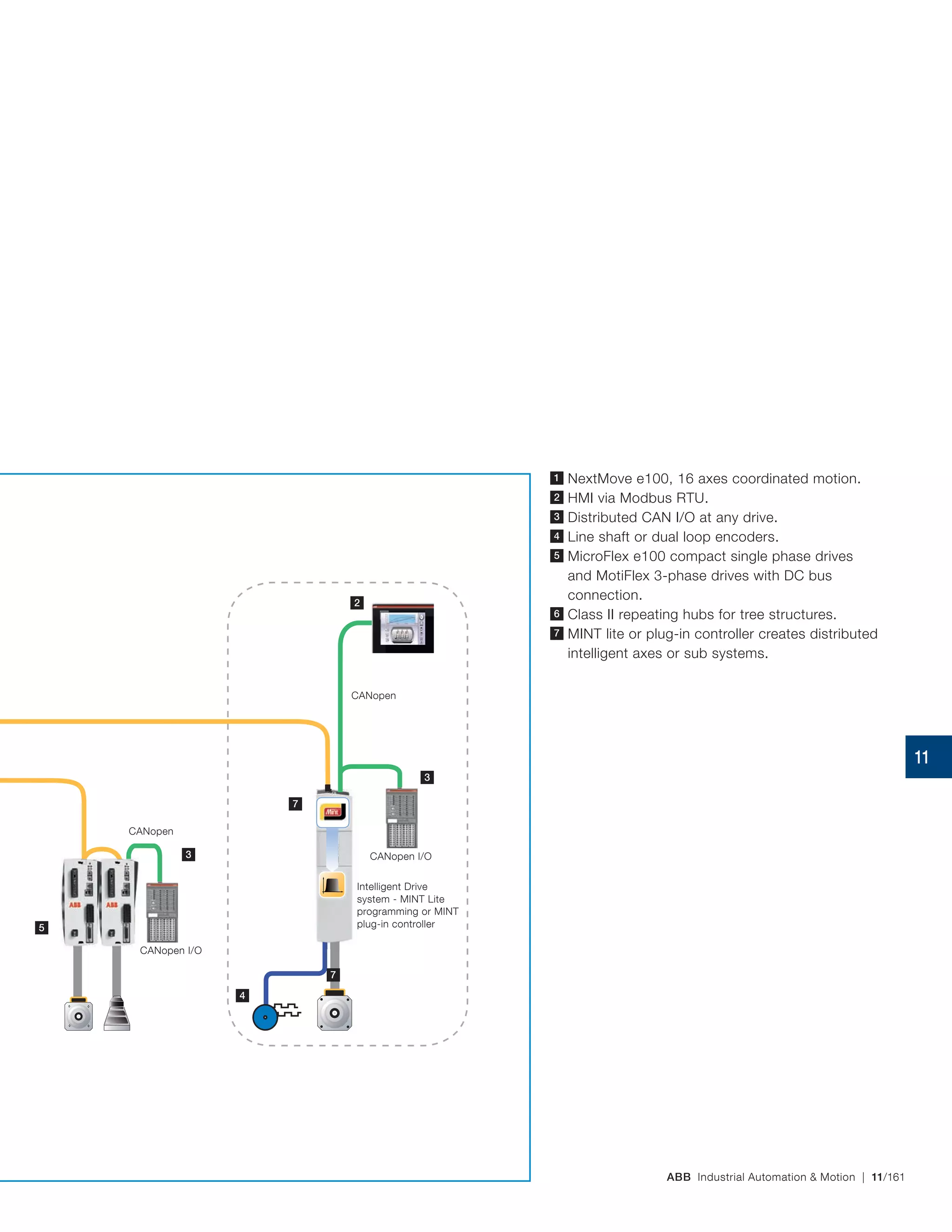

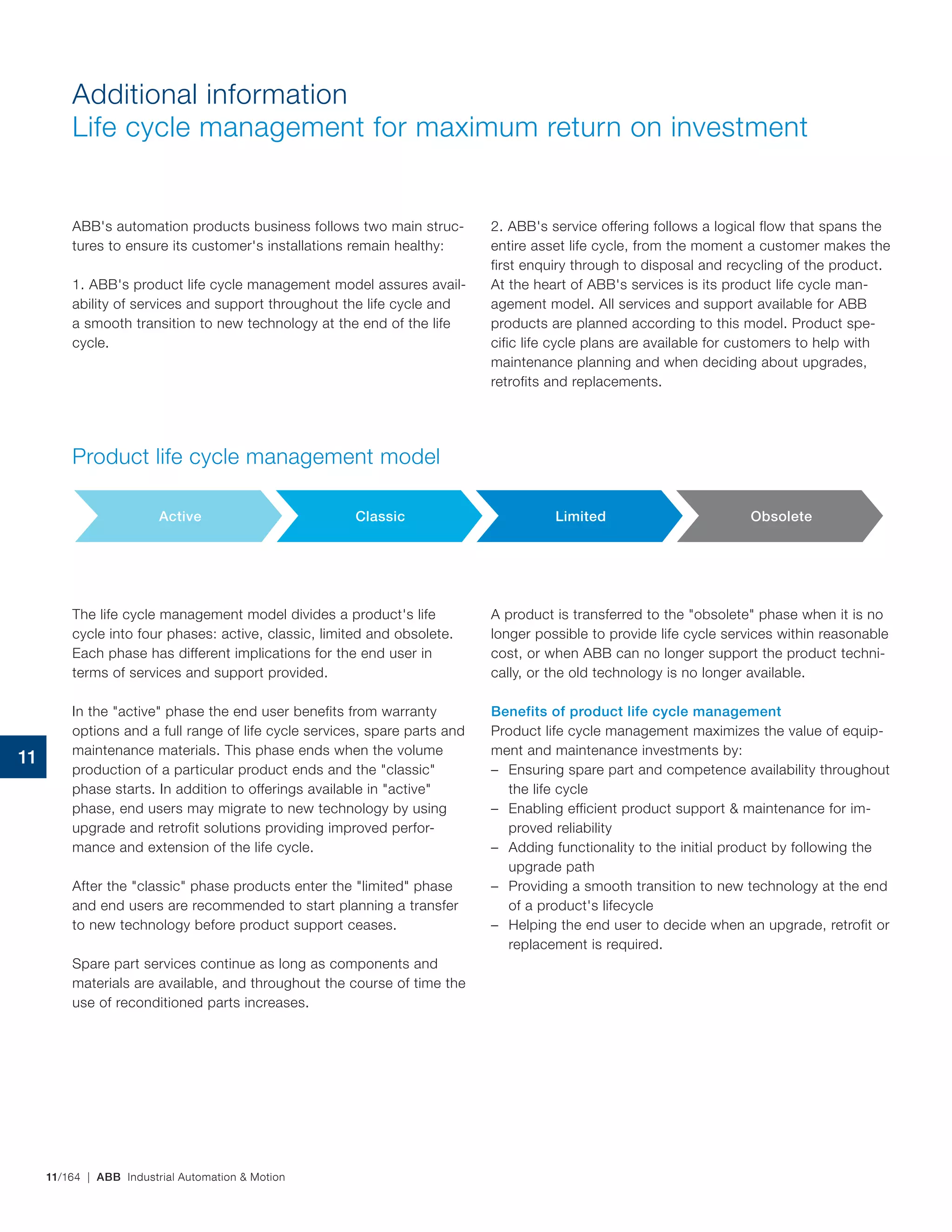

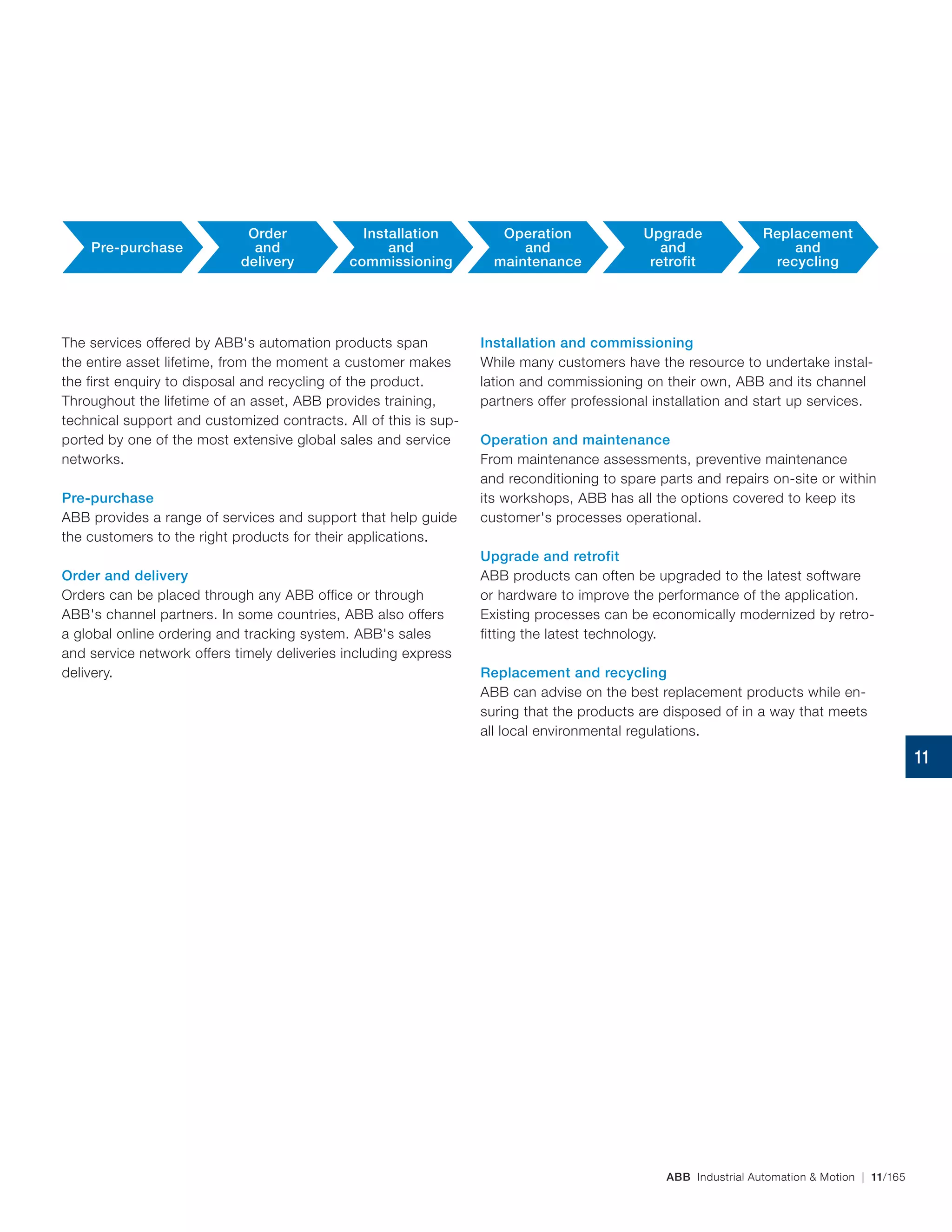

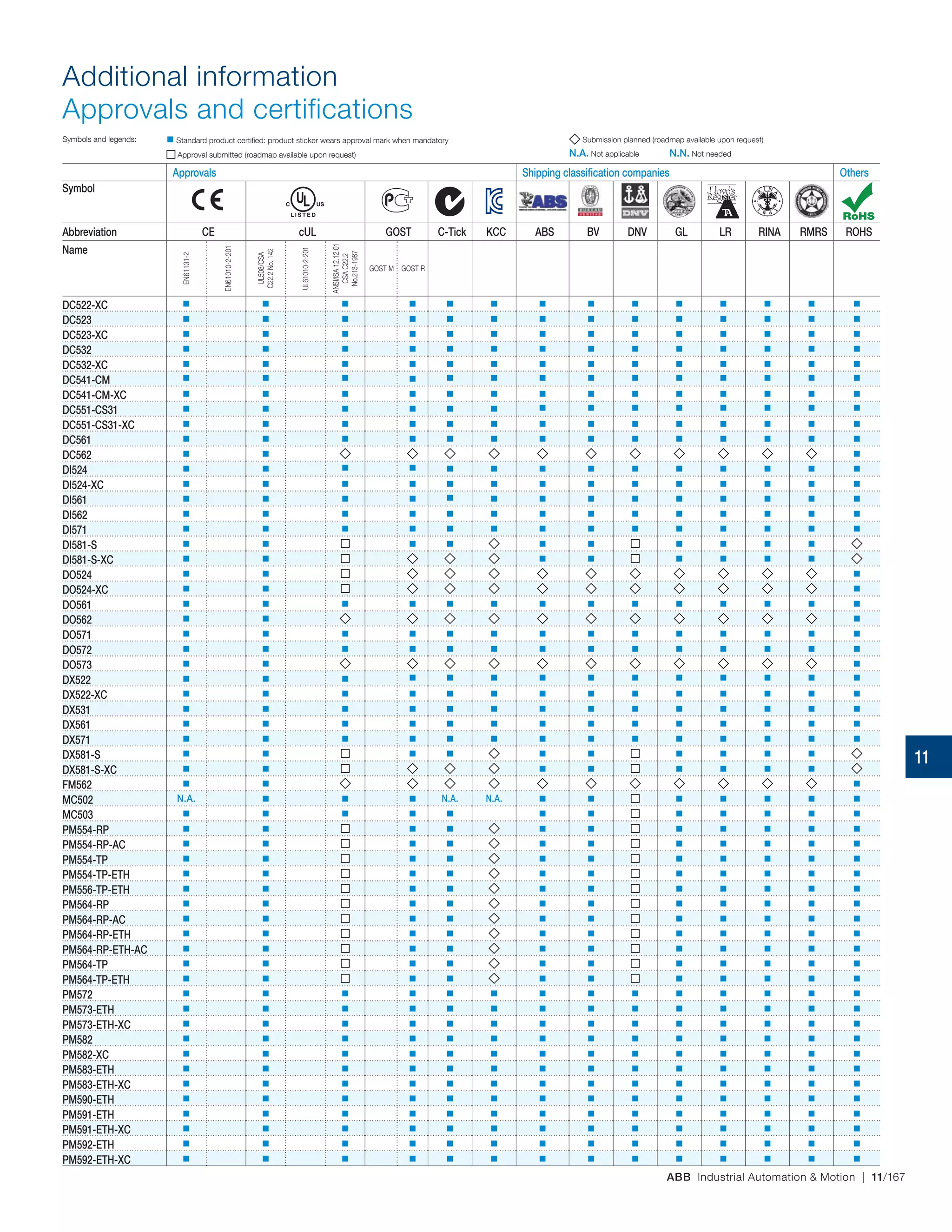

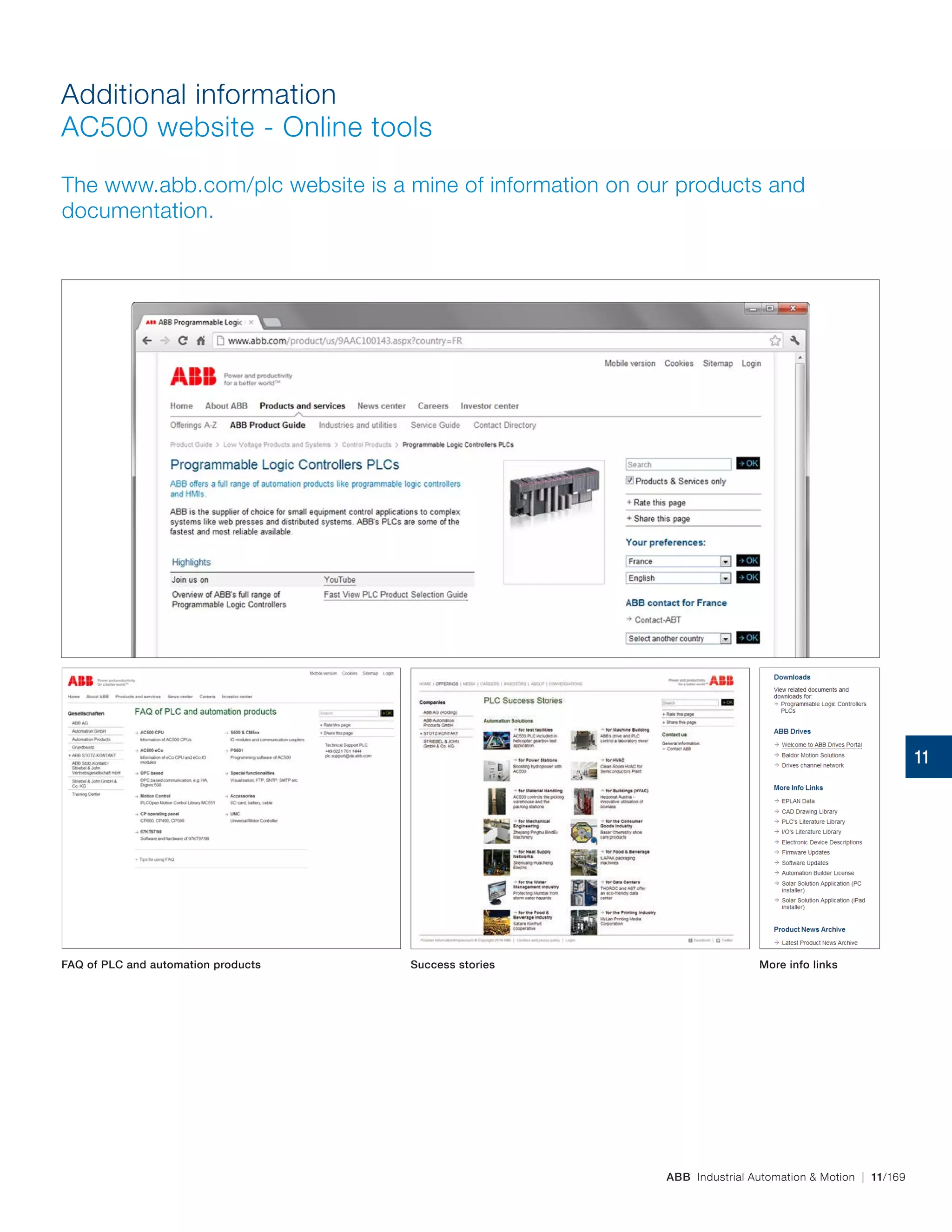

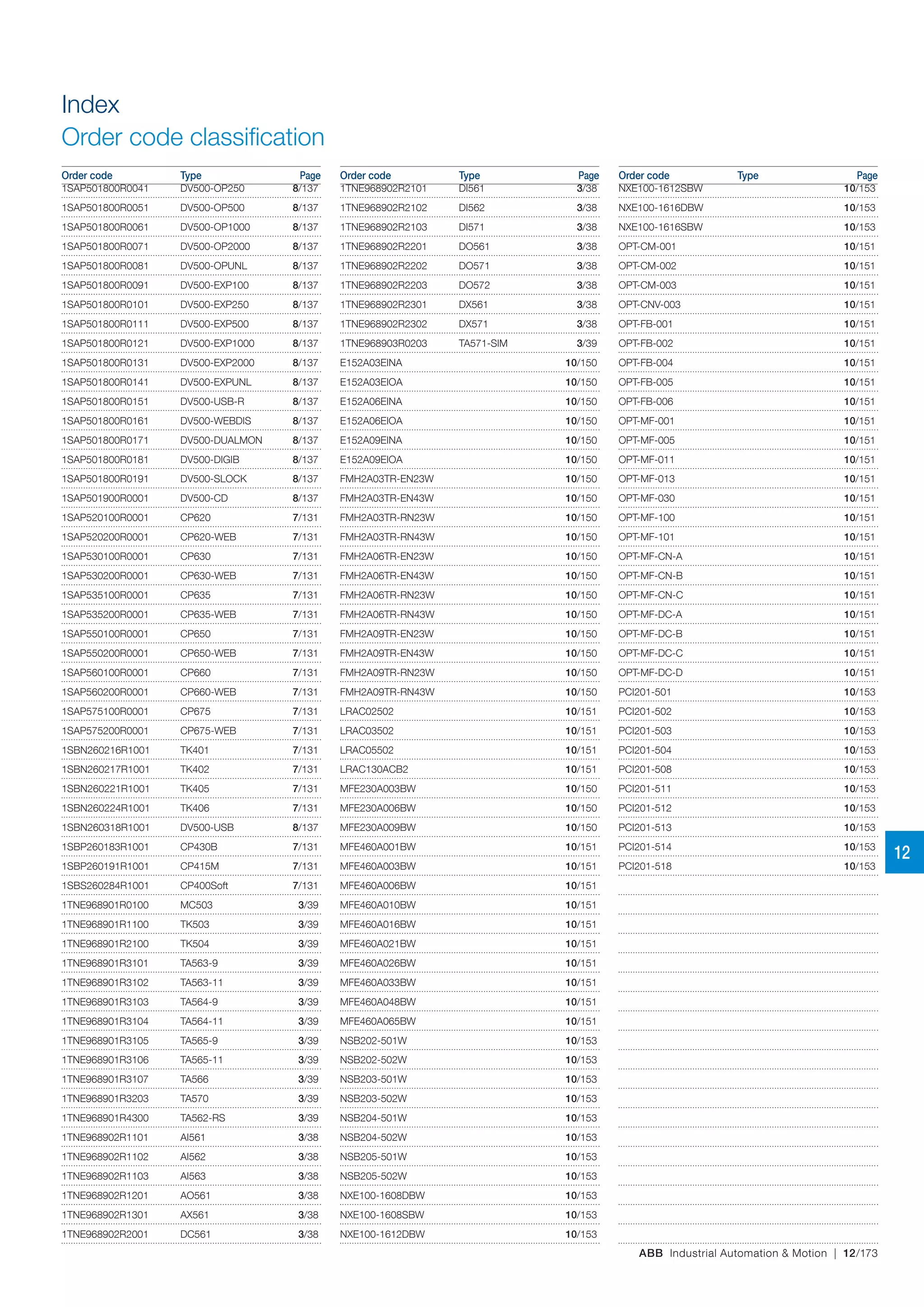

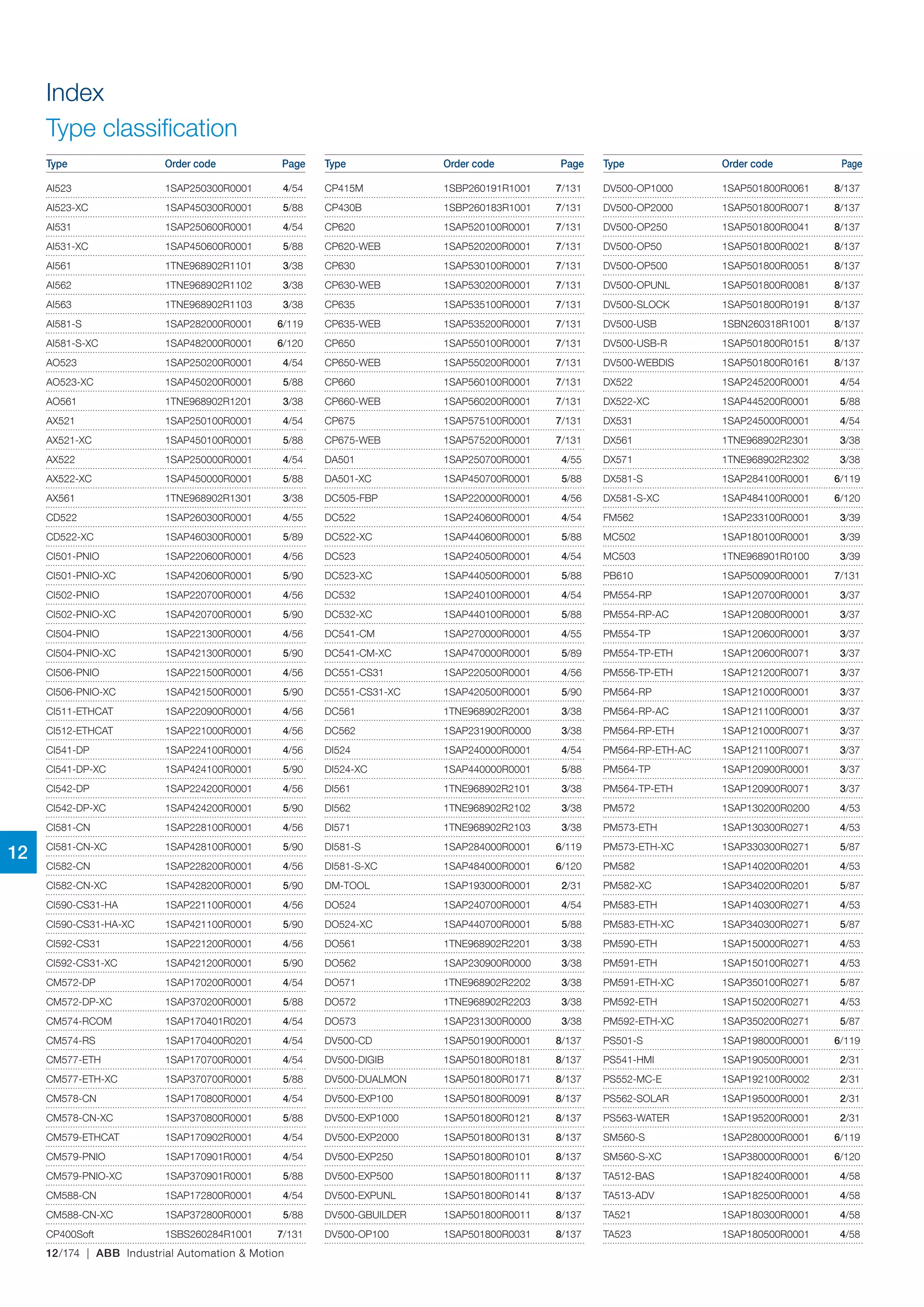

Industrial Automation & Motion catalog from ABB provides information on their programmable logic controllers (PLCs), human-machine interfaces (HMIs), drives, servo drives, and motion controllers. The catalog covers their product families including AC500 PLCs, CP600 and CP400 HMIs, low voltage drives, and motion control solutions. It also includes application descriptions and an index.