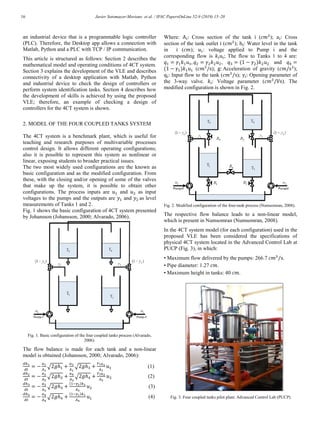

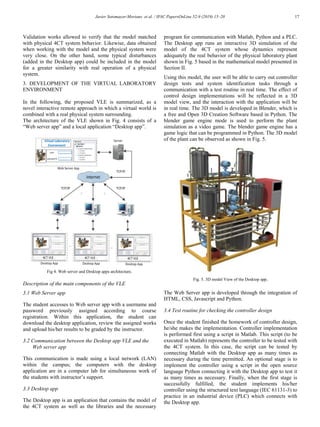

The document discusses the creation of a Virtual Laboratory Environment (VLE) designed for remote control design practices in multivariable processes via web browsers, facilitating the learning of controller design and system identification. The VLE is user-friendly, widely accessible, and cost-effective, using a reliable mathematical model and a dynamic interface for interactive learning. It emphasizes the benefits of using Python for development and aims to reduce the costs associated with traditional hands-on laboratories.