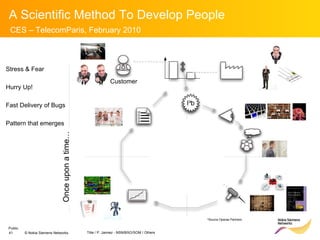

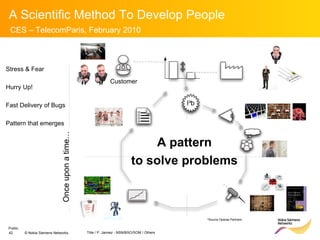

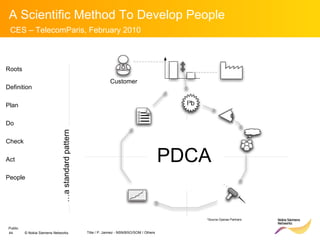

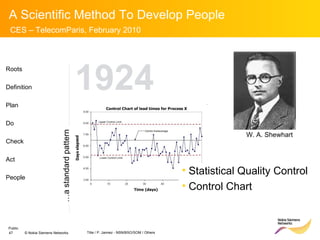

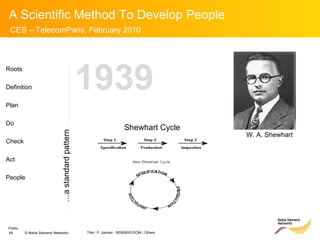

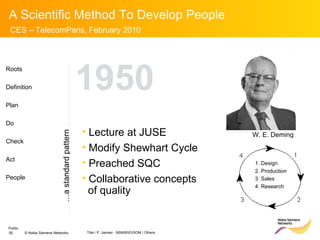

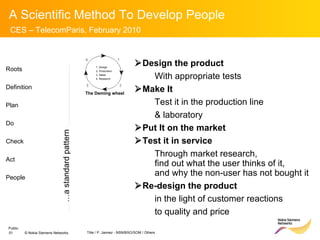

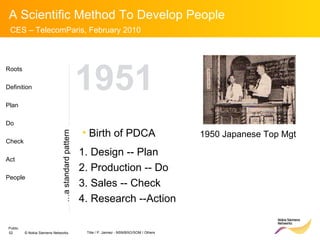

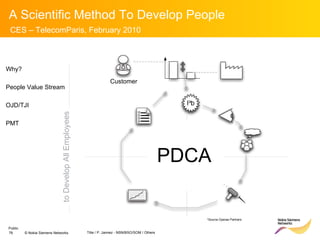

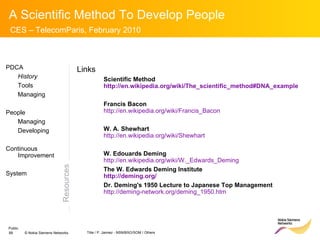

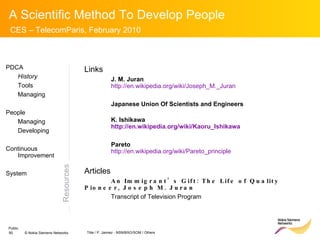

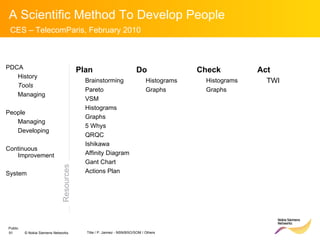

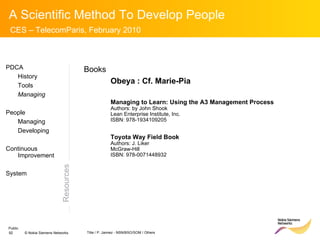

The document discusses the origins and evolution of the Plan-Do-Check-Act (PDCA) cycle, also known as the Deming cycle or Shewhart cycle. It traces the concept back to ideas of scientific experimentation in the 1600s and statistical process control methods developed in the 1920s-1940s. Key figures like Deming, Shewhart, Juran popularized applying the approach to quality management in manufacturing, especially in Japan from 1950 onwards. The cycle became a standard process for continuous improvement embraced by the quality movement.