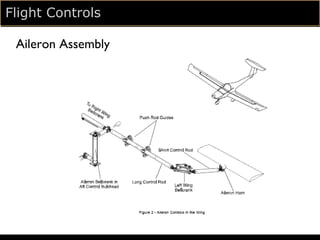

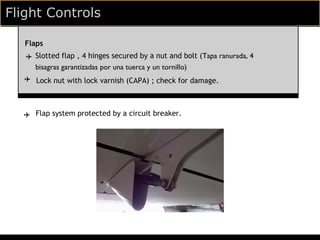

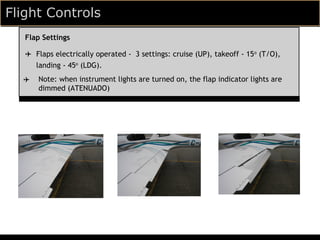

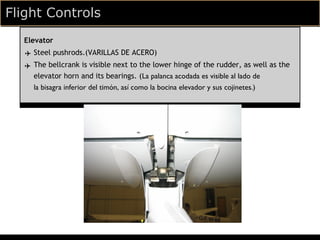

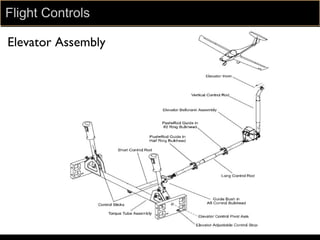

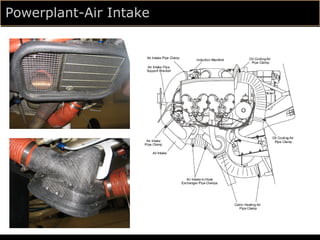

The document provides an overview of the key systems on a DA20 aircraft, including the airframe construction, flight controls, landing gear, engine and associated systems, electrical and navigation systems, and emergency procedures. It describes the composite material construction of the airframe and various control surfaces like the ailerons, flaps, elevator and rudder. It also outlines the hydraulic systems, fuel and lubrication systems, electrical power generation and ignition. Performance charts and annunciations/alerts are also mentioned.