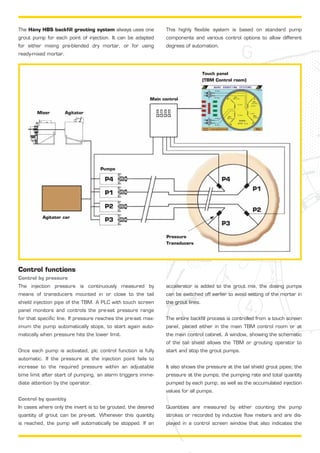

The Häny HBS Backfill Grouting System is designed for pressure-controlled grouting behind TBM tunneling, allowing for both full annulus and invert segment filling. It features programmable automation for grouting operations, using standard pumps and touch screen controls for real-time monitoring of pressure and quantity. The system is versatile, enabling pre-excavation grouting, maintenance operations, and efficient mixing and injection of materials.