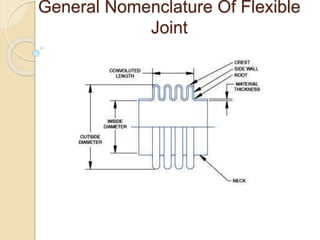

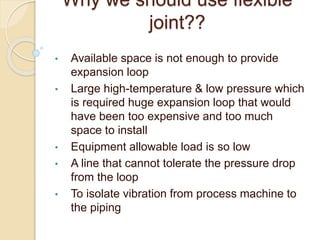

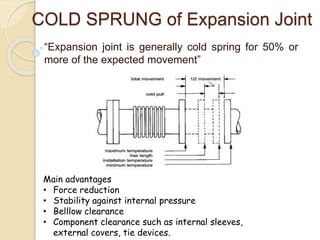

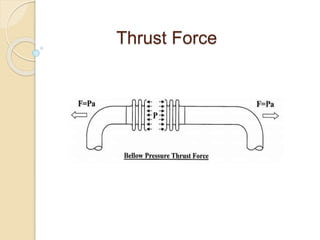

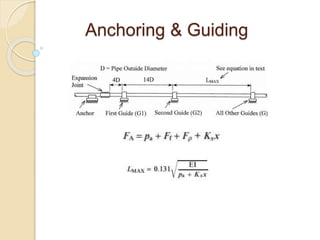

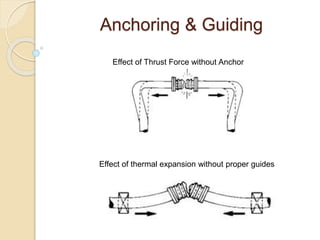

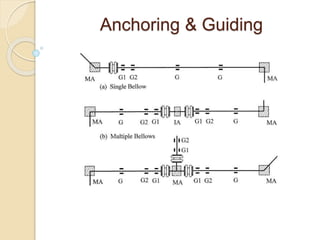

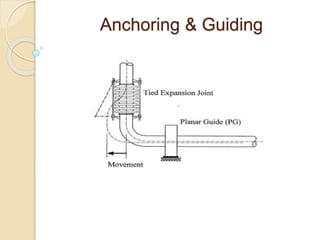

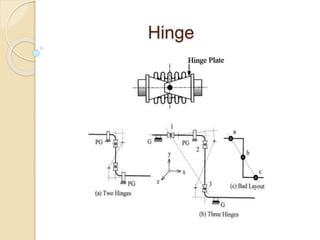

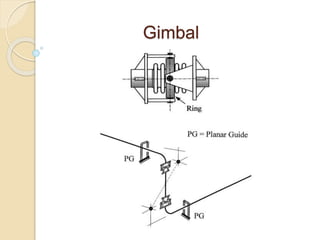

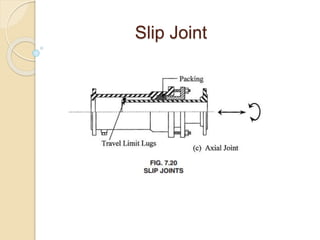

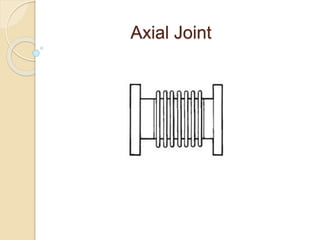

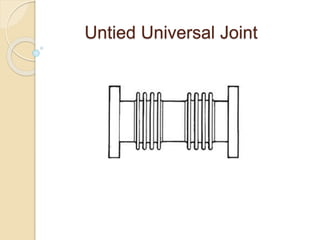

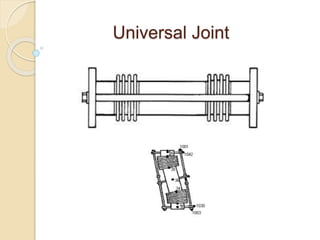

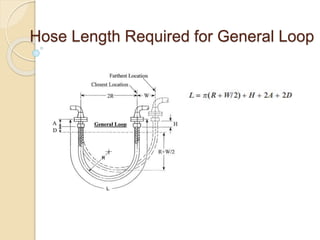

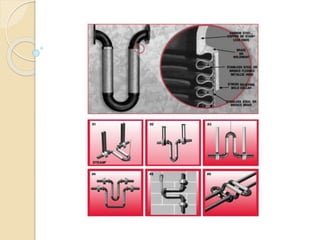

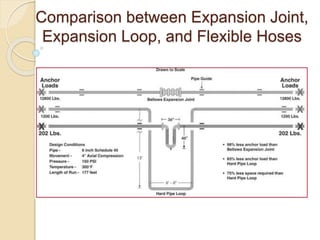

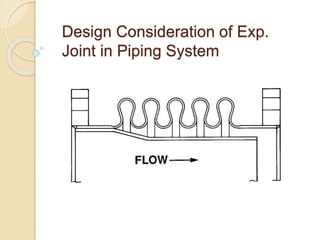

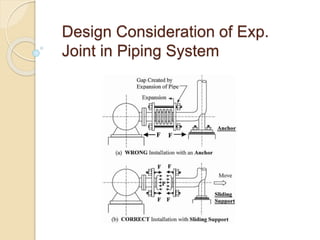

This document discusses flexible connections in piping systems. Flexible joints, such as bellow expansion joints, are used to absorb thermal expansion or movement between pipes. There are several types of flexible joints, including hinge joints, gimbal joints, slip joints, axial joints, untied universal joints, and universal joints. Flexible hoses can also be used to connect distant points with movement. When designing flexible joints, it is important to consider the expected movement, thrust forces, anchoring and guiding, and how they will be incorporated into the overall piping system design. Flexible connections require special engineering due to their extra costs and need for periodic inspection and maintenance.