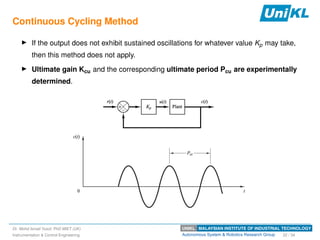

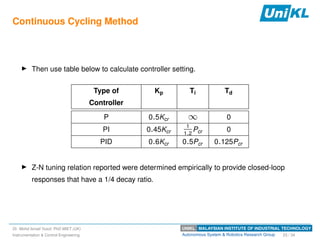

This document discusses control system tuning methods. It introduces the continuous cycling method developed by Ziegler and Nichols, which determines controller parameters by increasing proportional gain until sustained oscillations occur. The ultimate gain and period are then used to calculate PID settings. Issues with this method include the trial and error nature and potential for process instability. The step test method is also presented, which applies a step input in open loop to determine time delay and time constant from the response curve. These values are then used to calculate PID parameters. Examples are given to illustrate application of these tuning techniques.