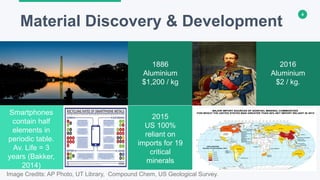

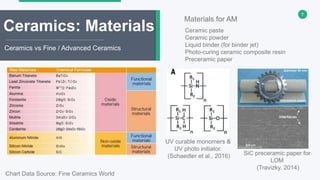

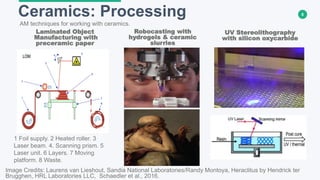

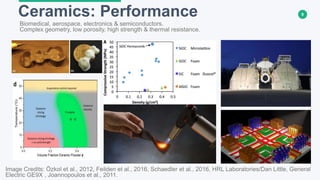

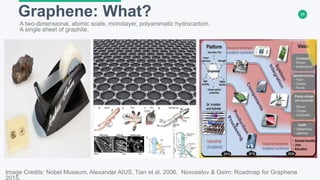

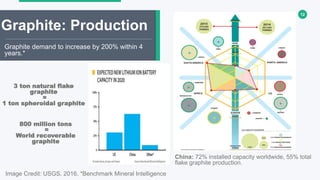

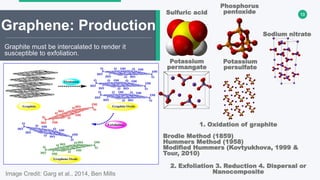

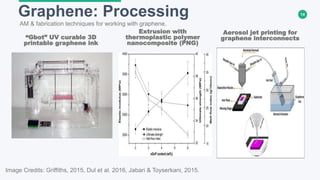

The document discusses advancements in 3D printing with novel materials, particularly focusing on ceramics and graphene, highlighting their processing, performance, and future applications. It presents an agenda covering material discovery, development, and the efficiency of manufacturing processes, alongside an overview of critical material dependencies and environmental considerations. The analysis also includes insights into various additive manufacturing techniques and implications for industries such as aerospace, electronics, and biomedicine.