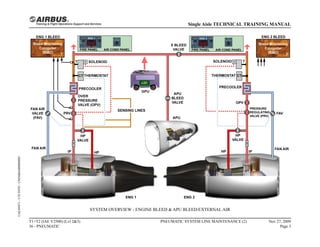

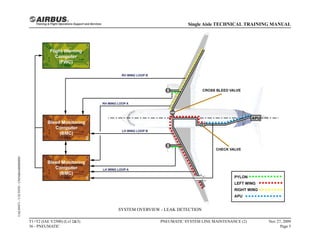

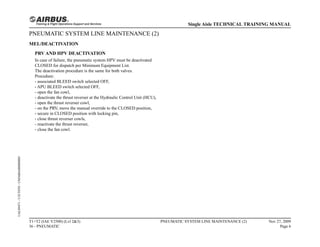

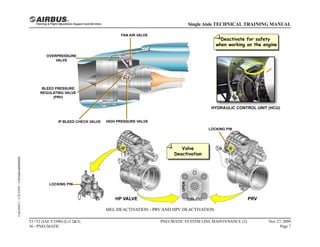

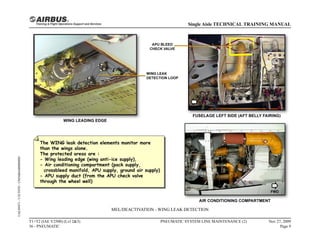

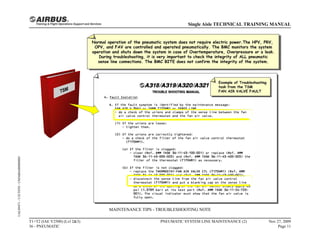

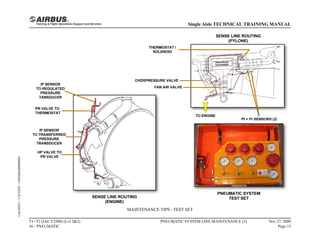

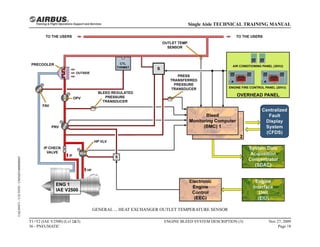

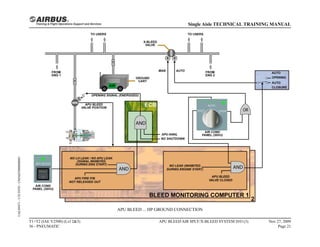

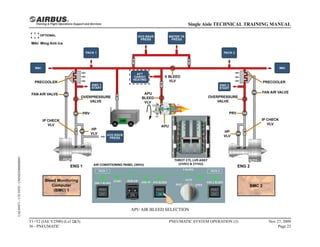

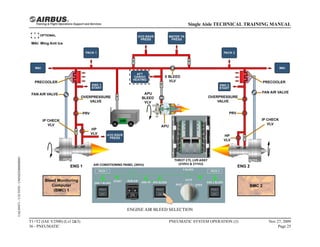

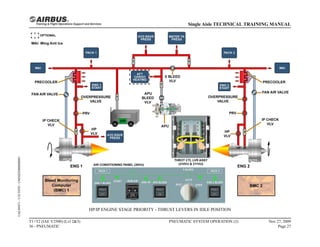

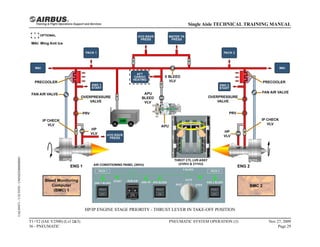

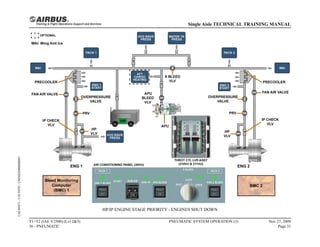

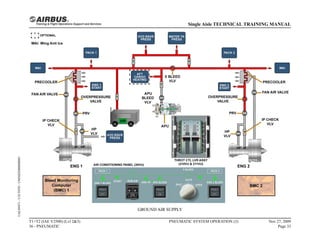

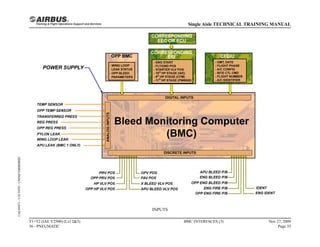

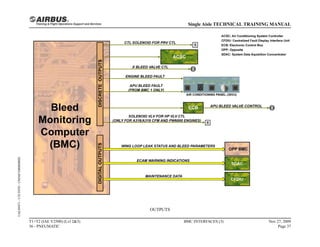

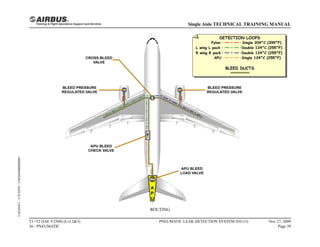

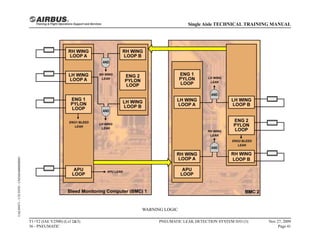

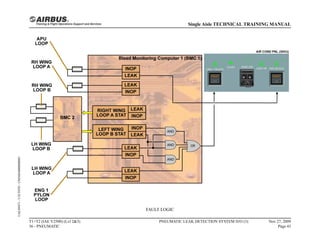

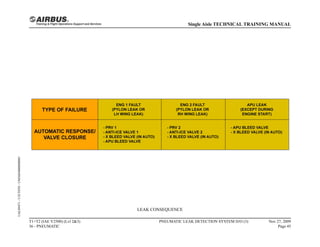

The document is a technical training manual for the pneumatic system of the IAE V2500 engines, specifically focused on levels 2 and 3 maintenance and operation. It covers various aspects such as engine bleed air systems, leak detection, and troubleshooting procedures, emphasizing that the manual is intended purely for training purposes and should not be used as a reference. The manual also details safety procedures, component operations, and interconnections critical for maintaining the pneumatic system effectively.