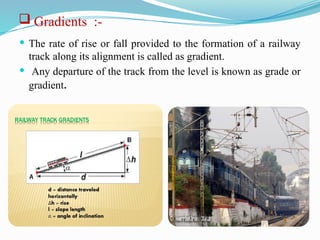

The document discusses various aspects of railway engineering, including rail joints, welding techniques, and gradient types. It highlights the advantages of welded rails, such as increased rail life, reduced maintenance costs, and improved passenger comfort. Additionally, it explains different gradient types used in railways, their purposes, and specifications for construction.