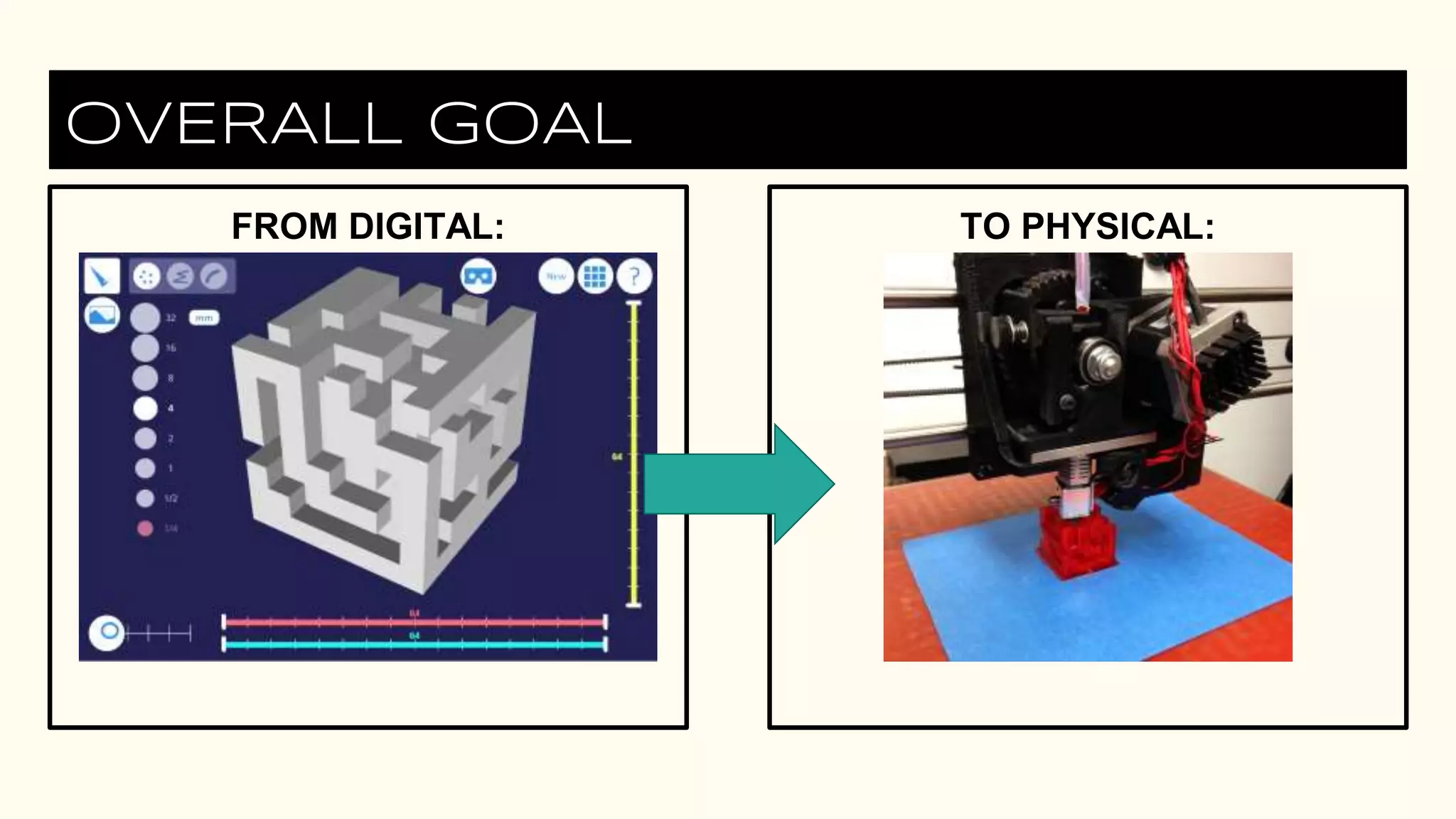

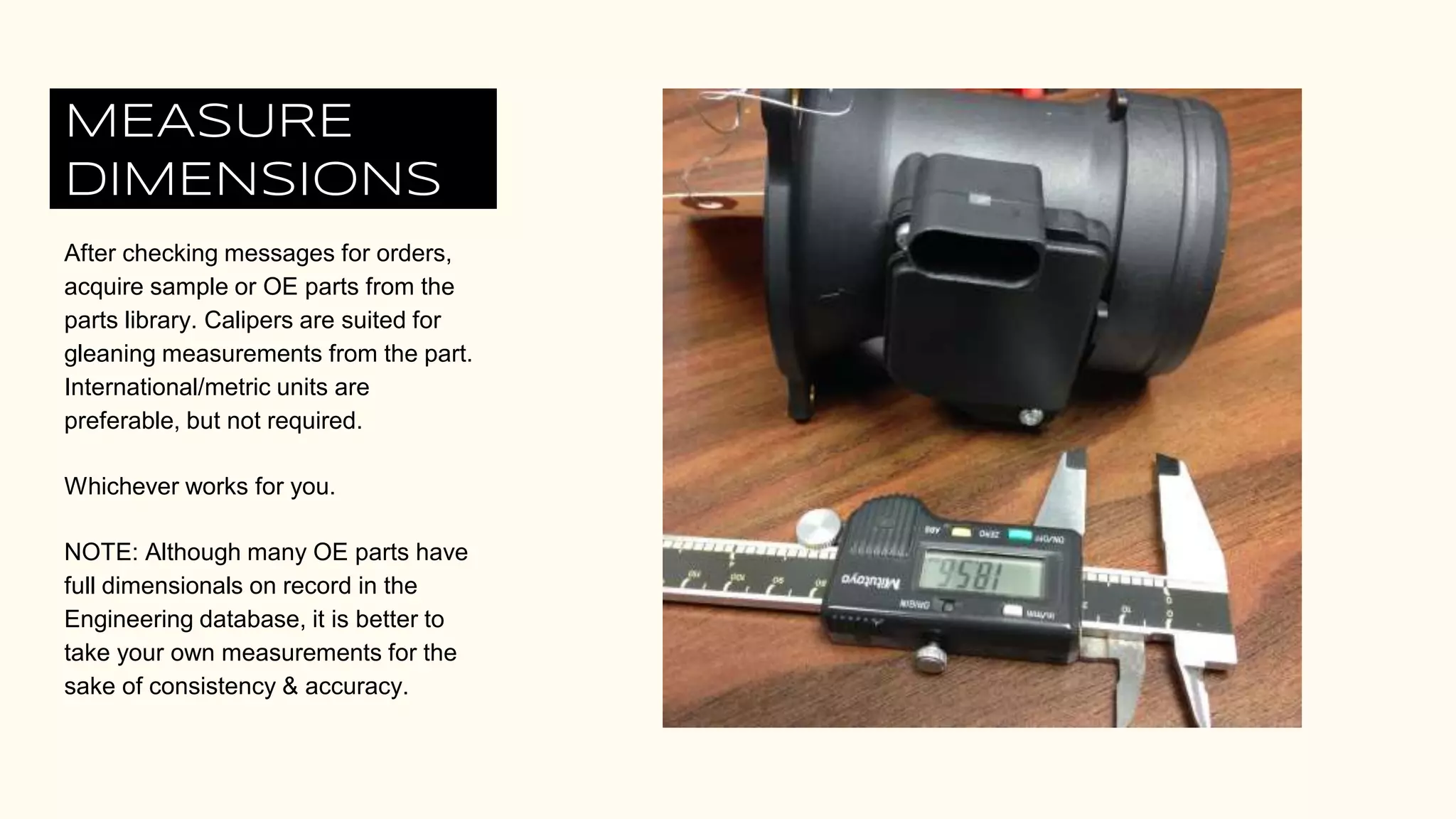

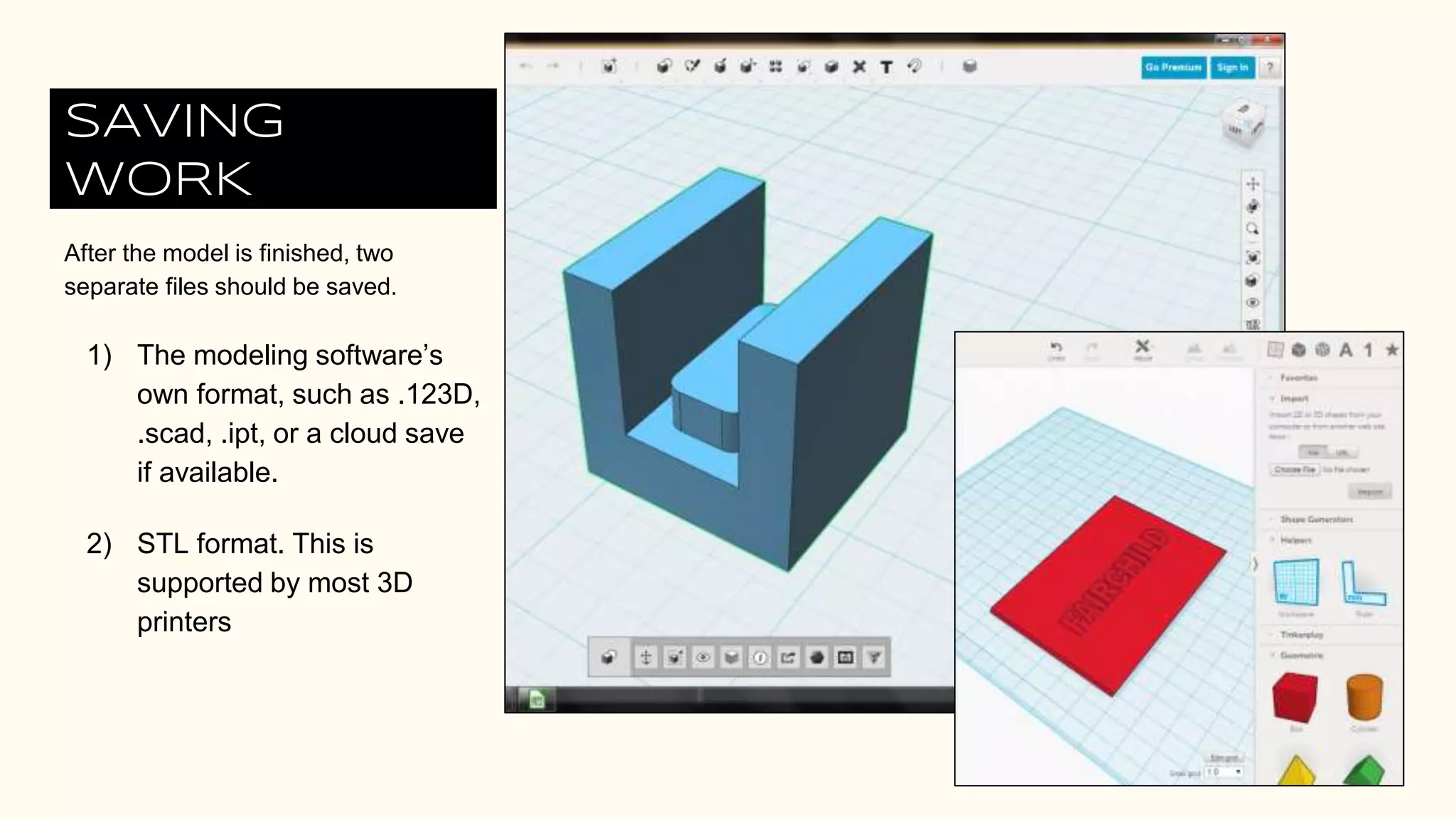

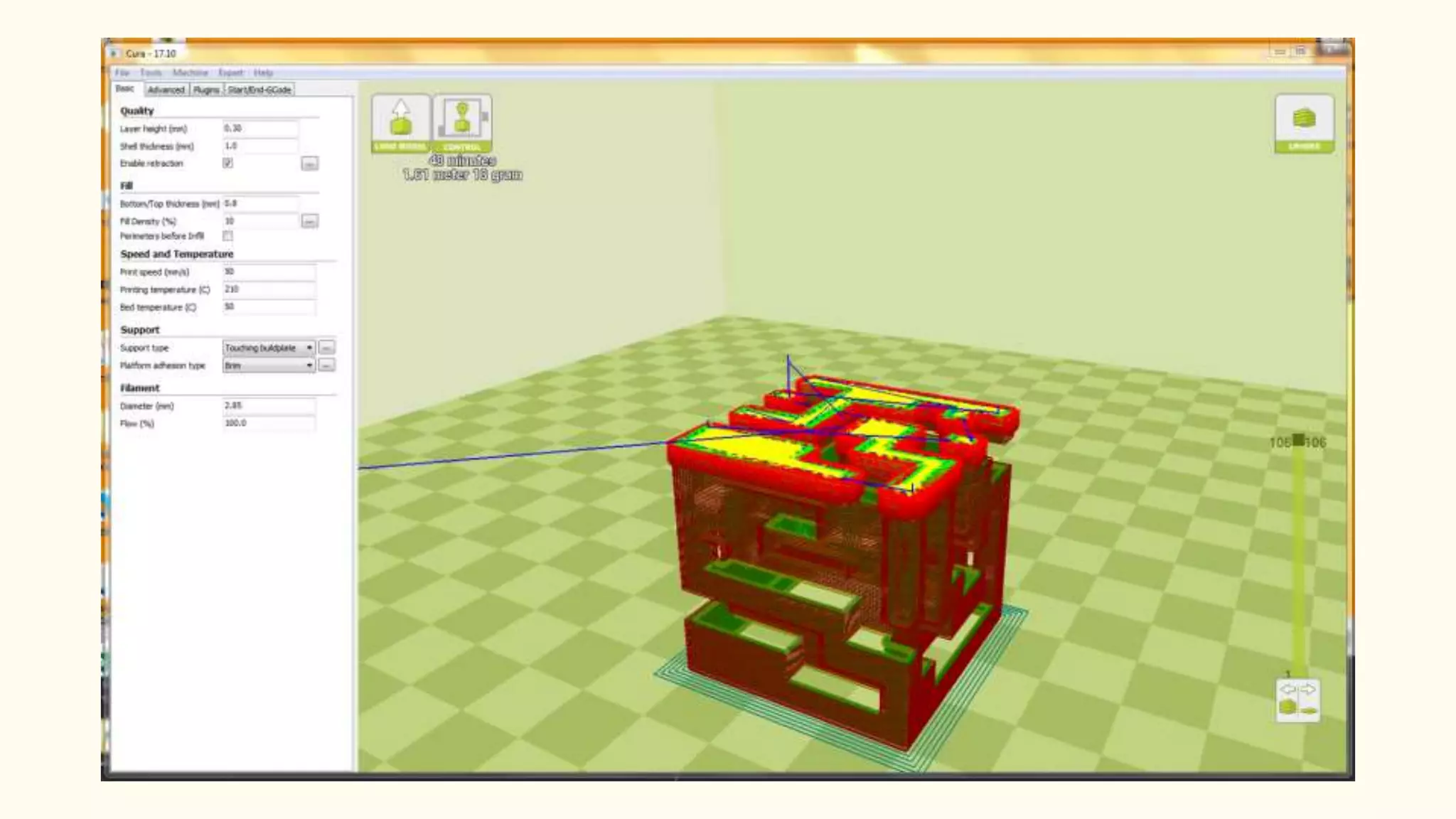

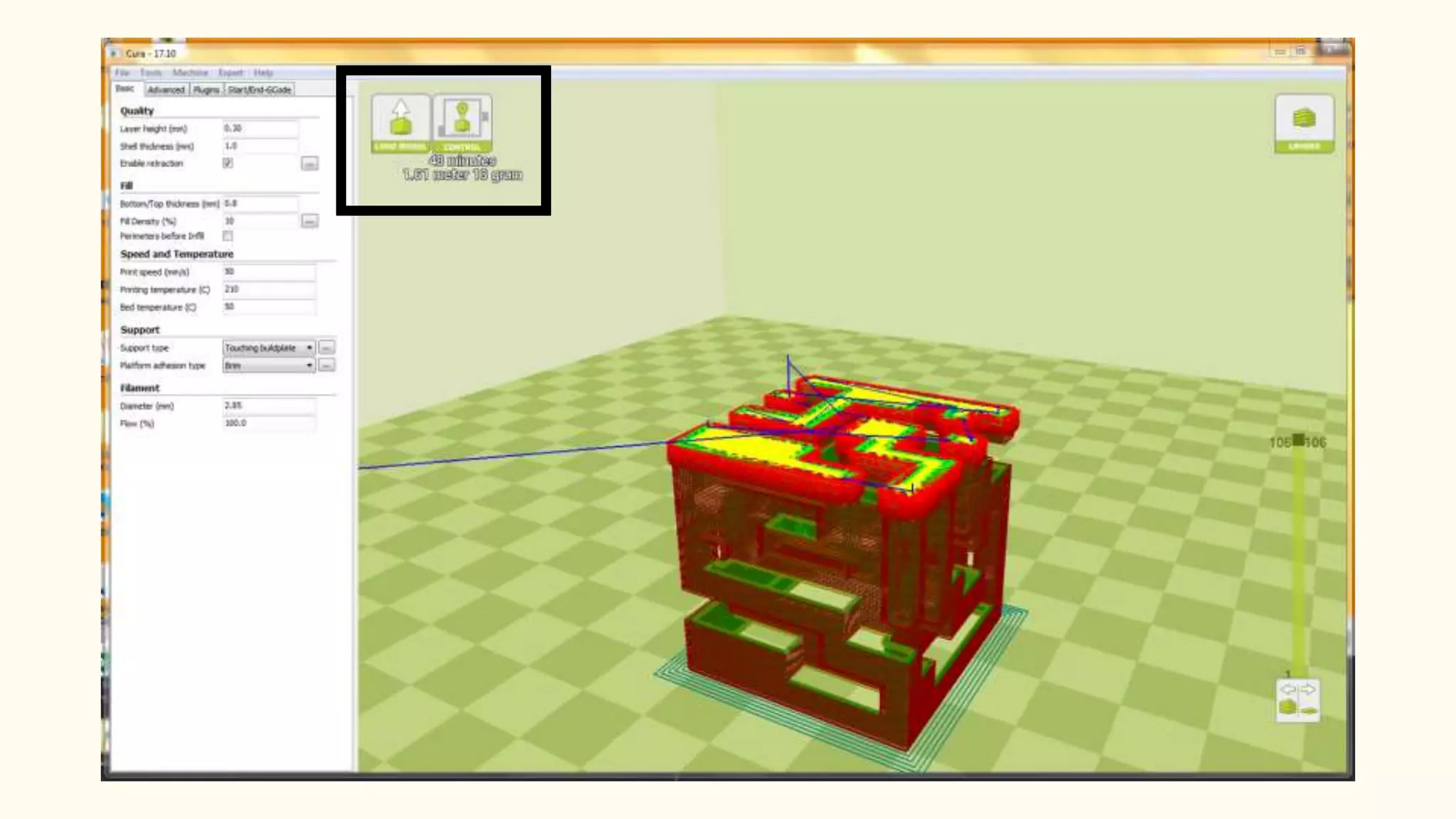

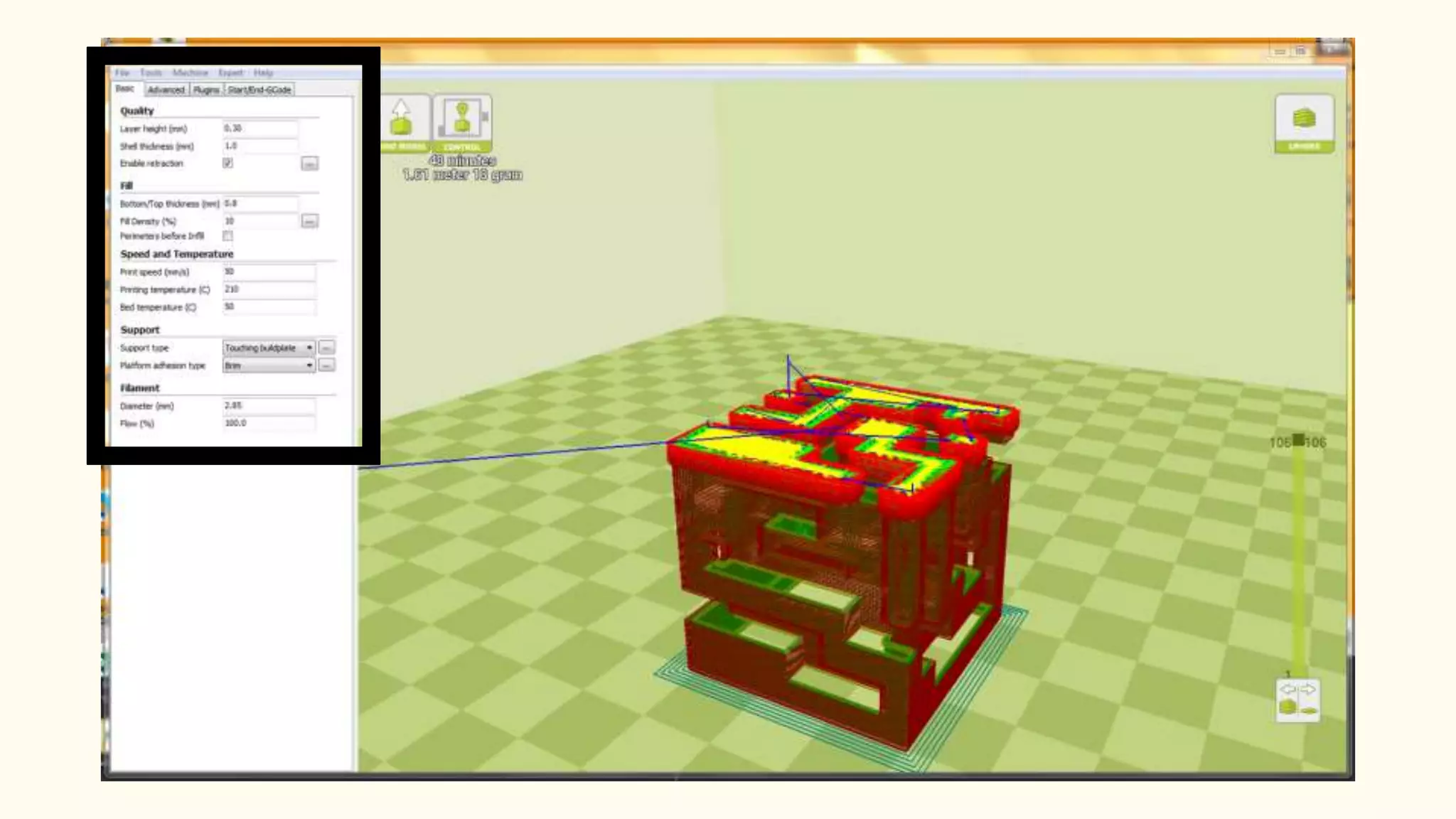

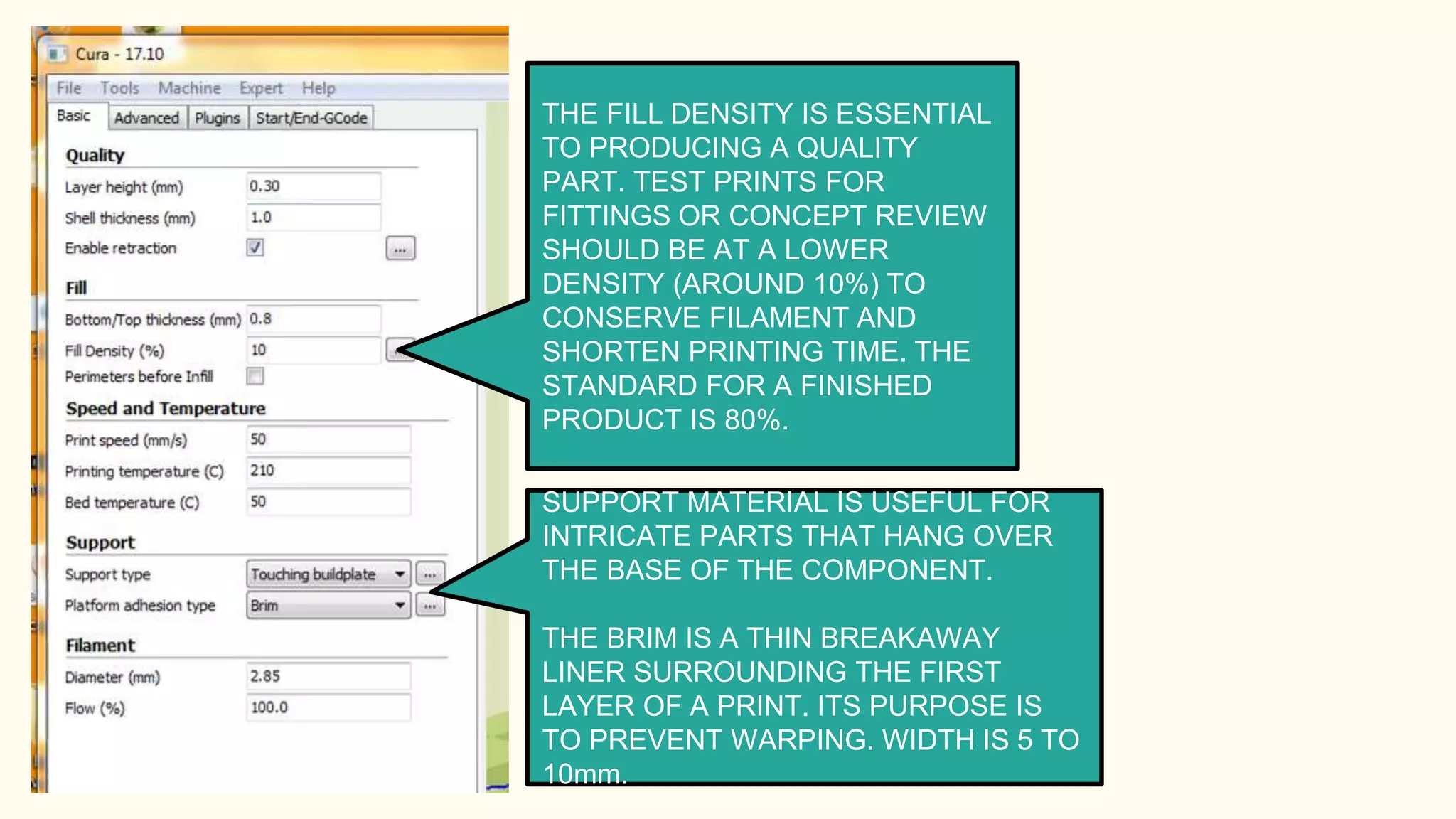

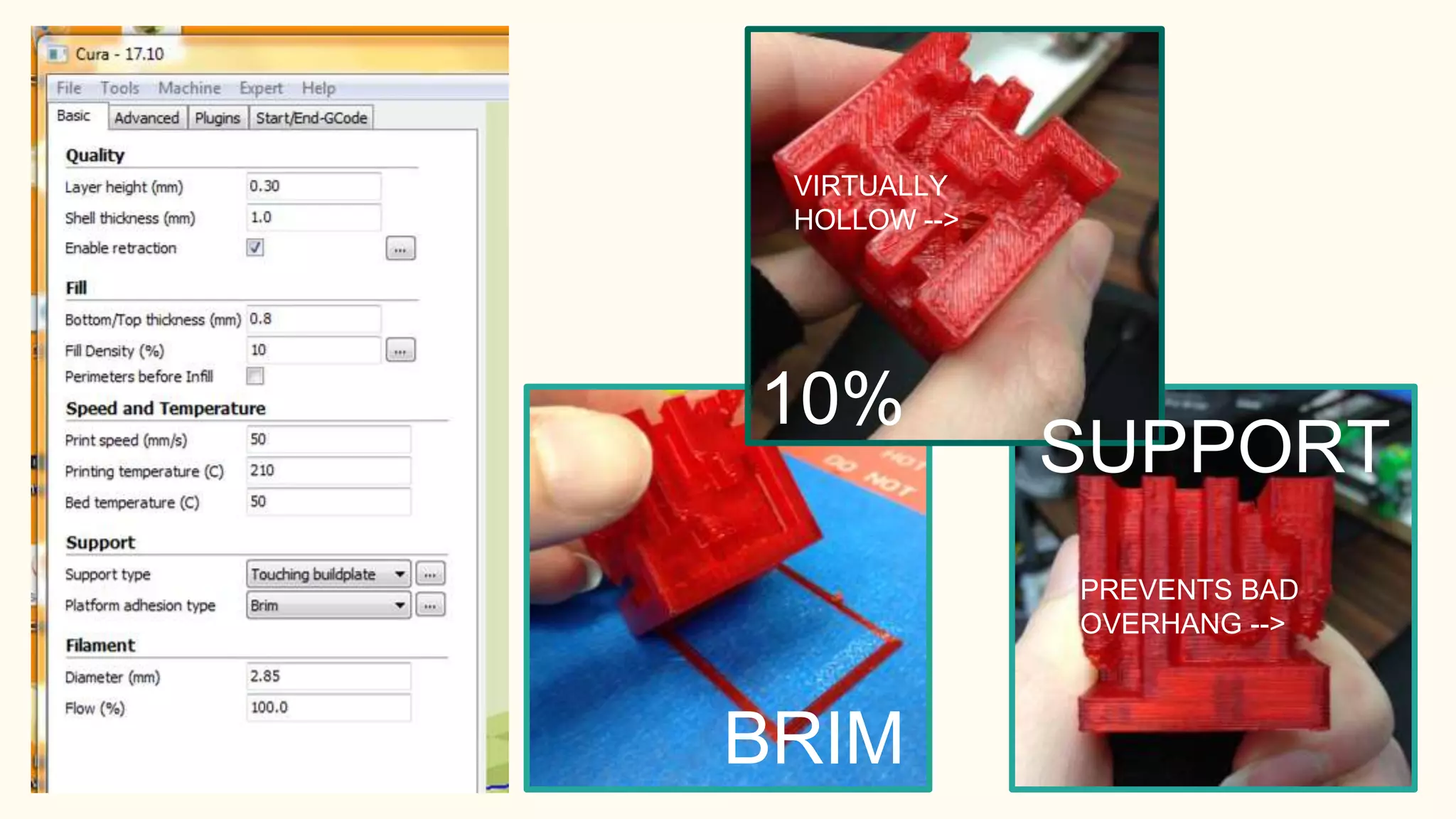

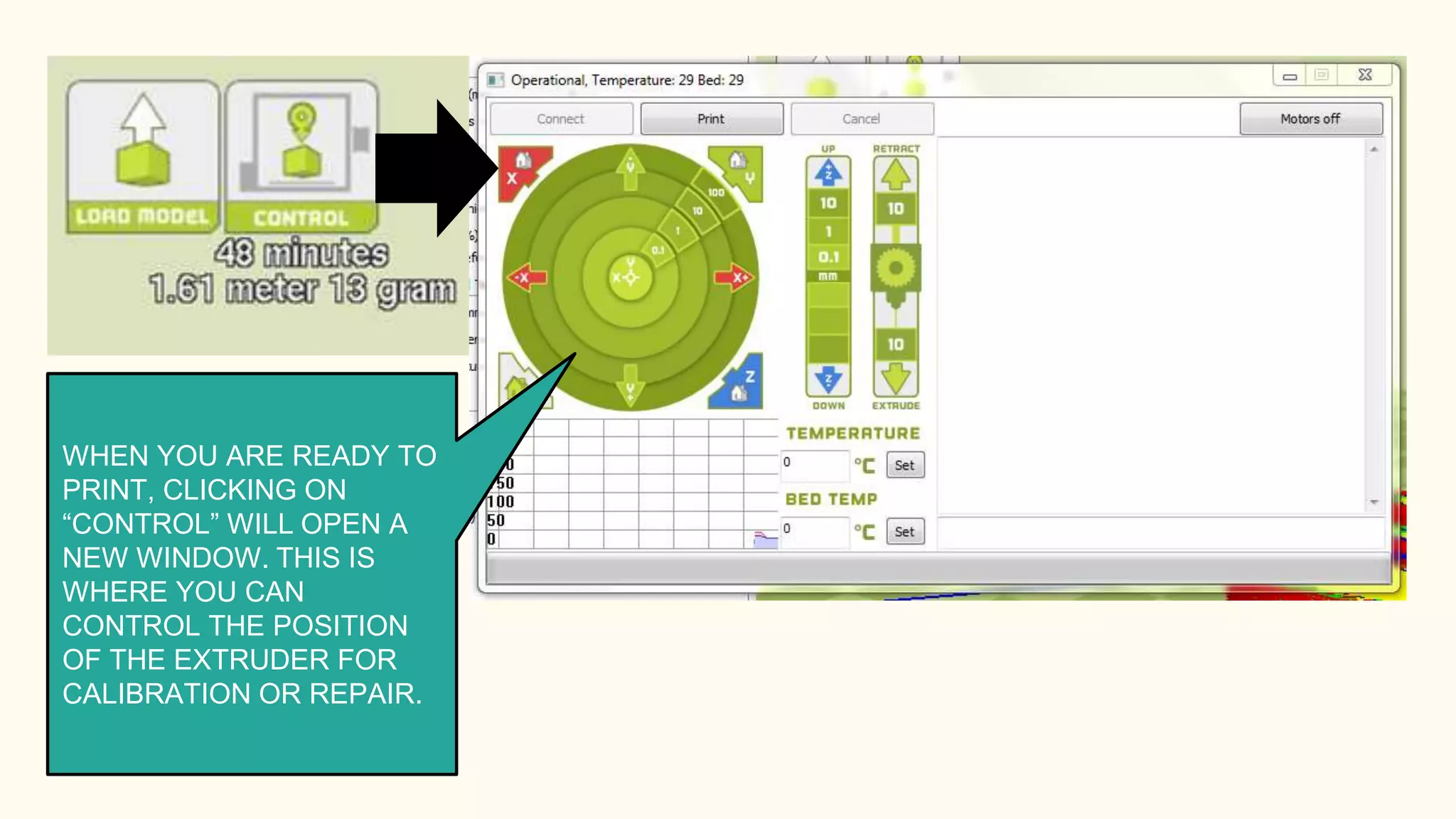

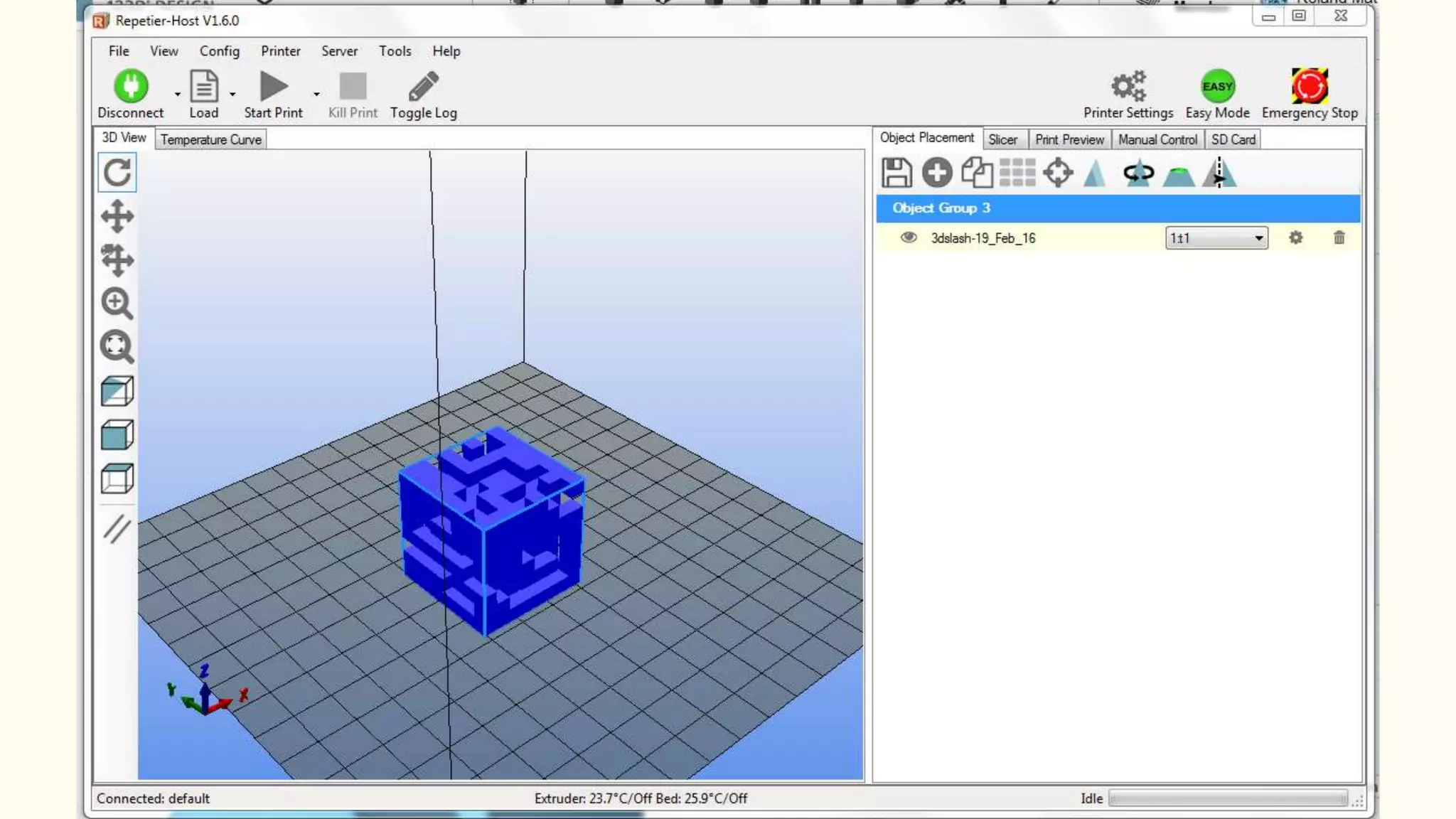

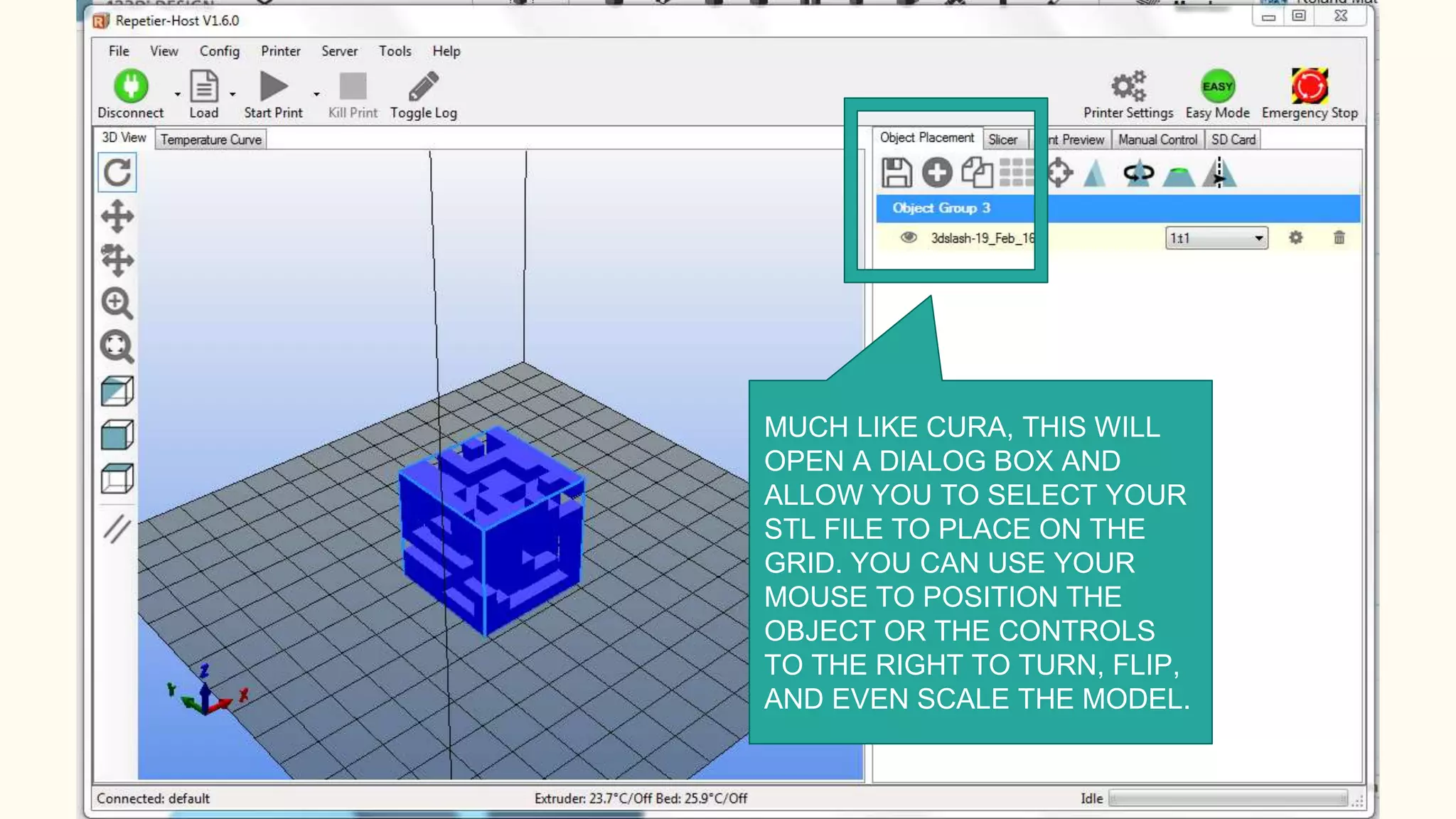

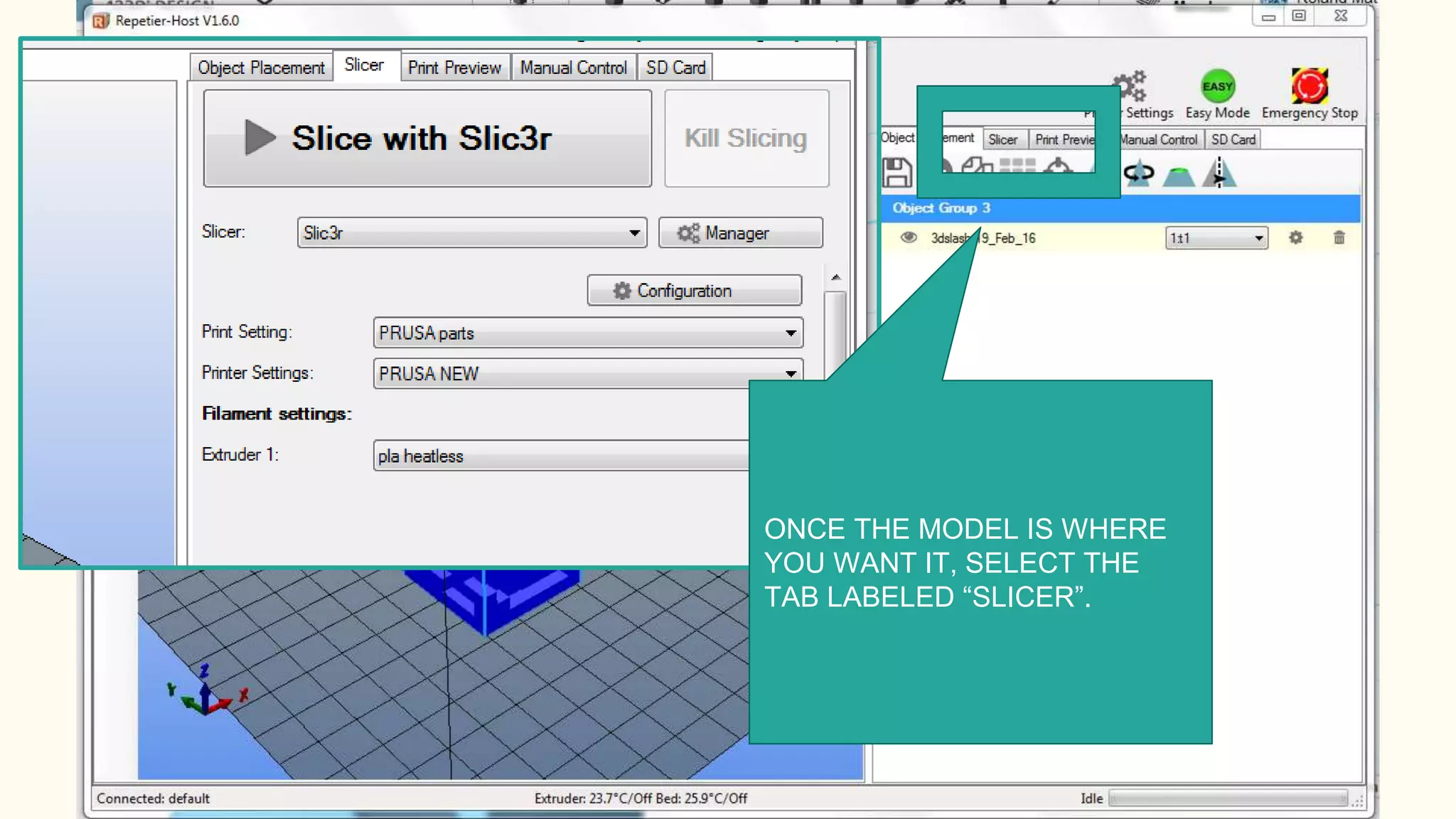

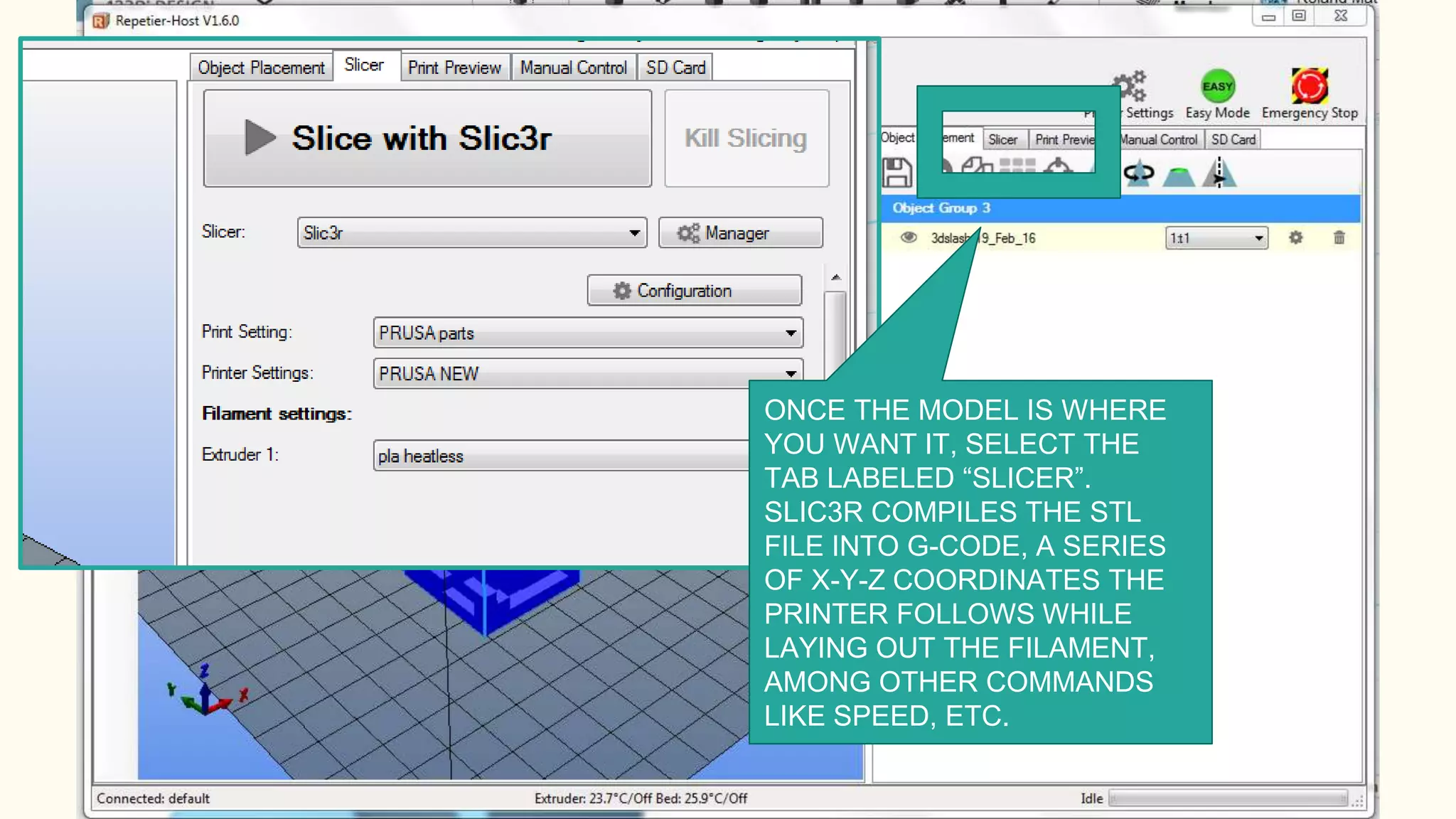

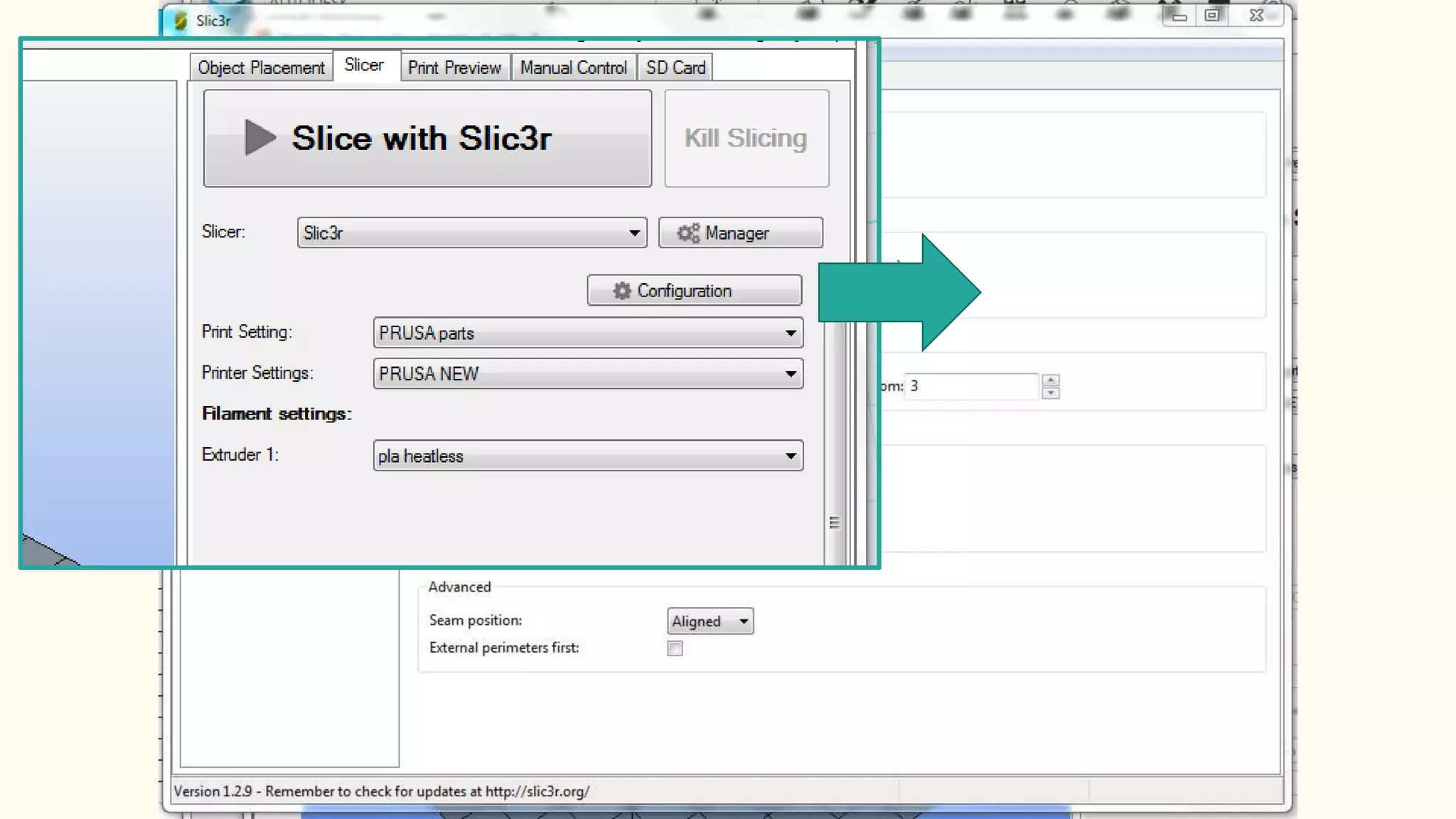

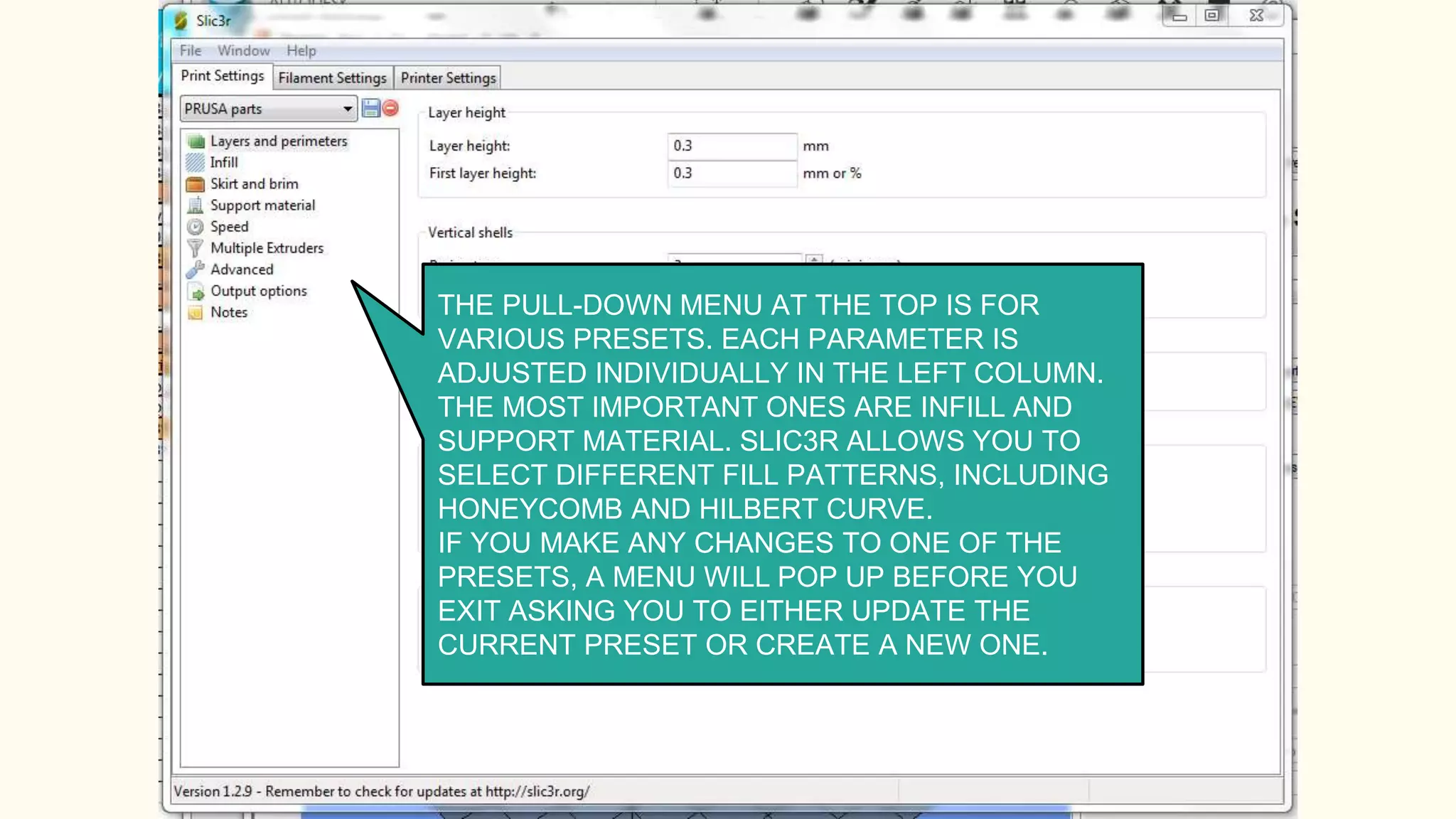

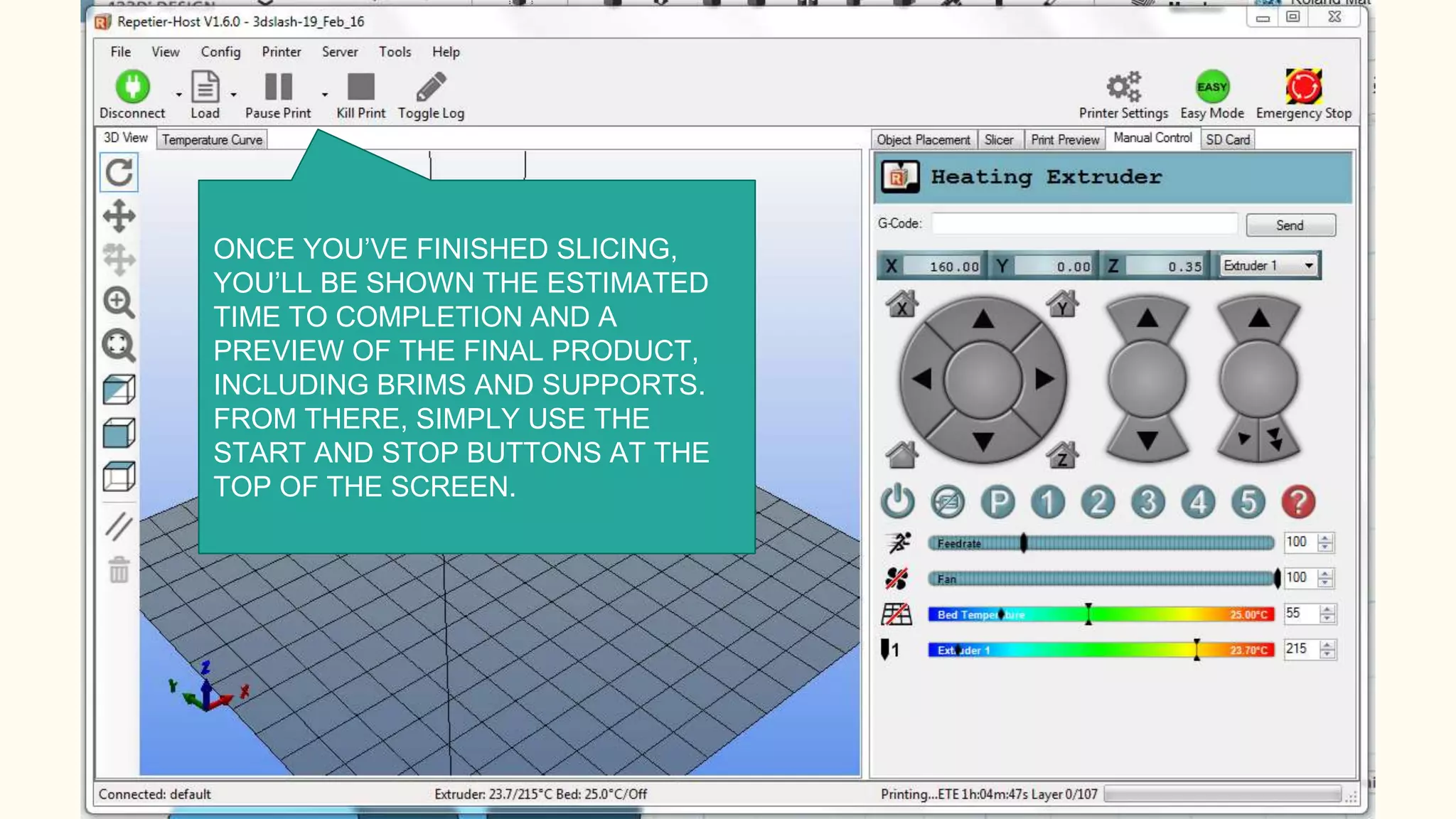

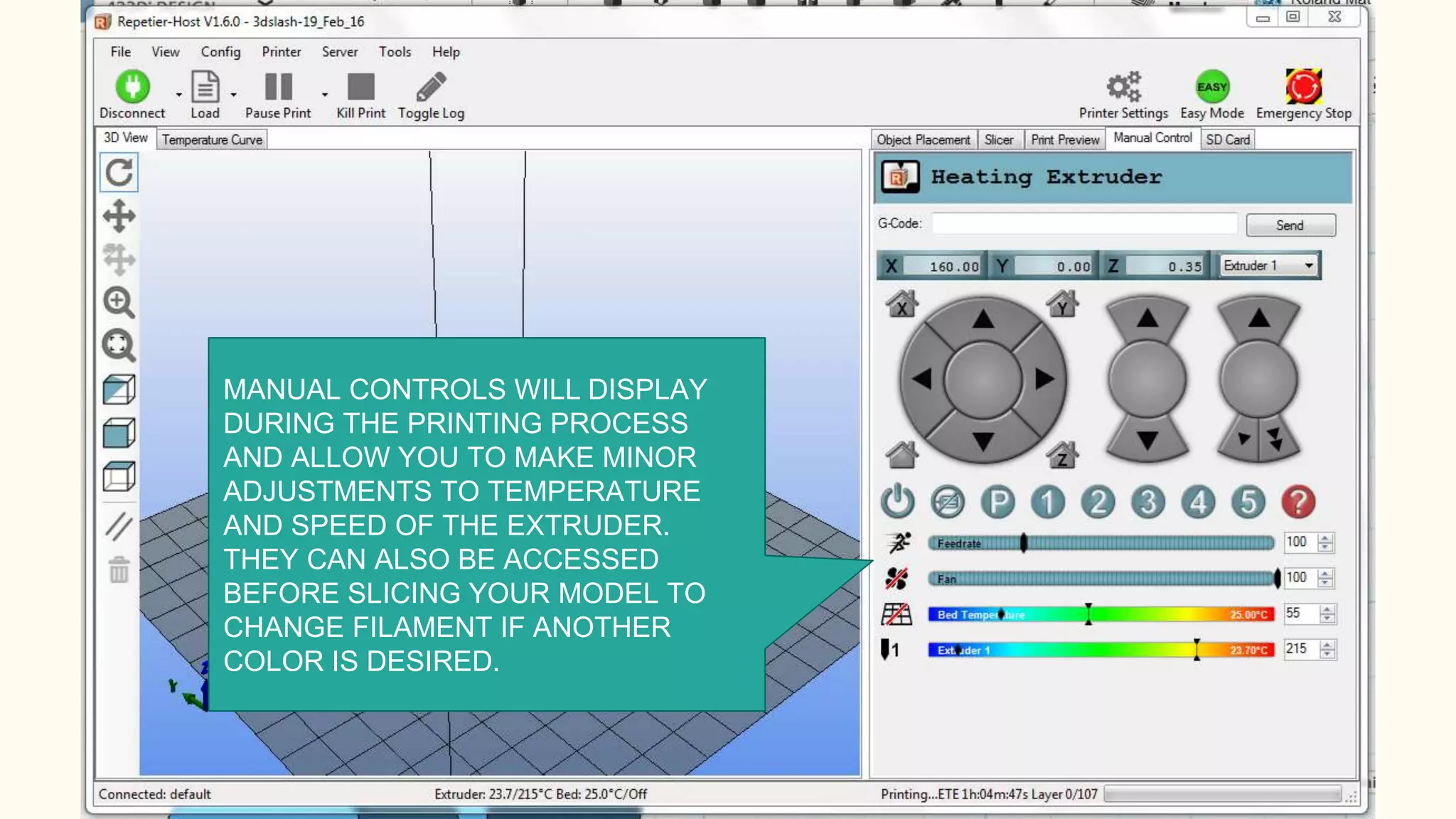

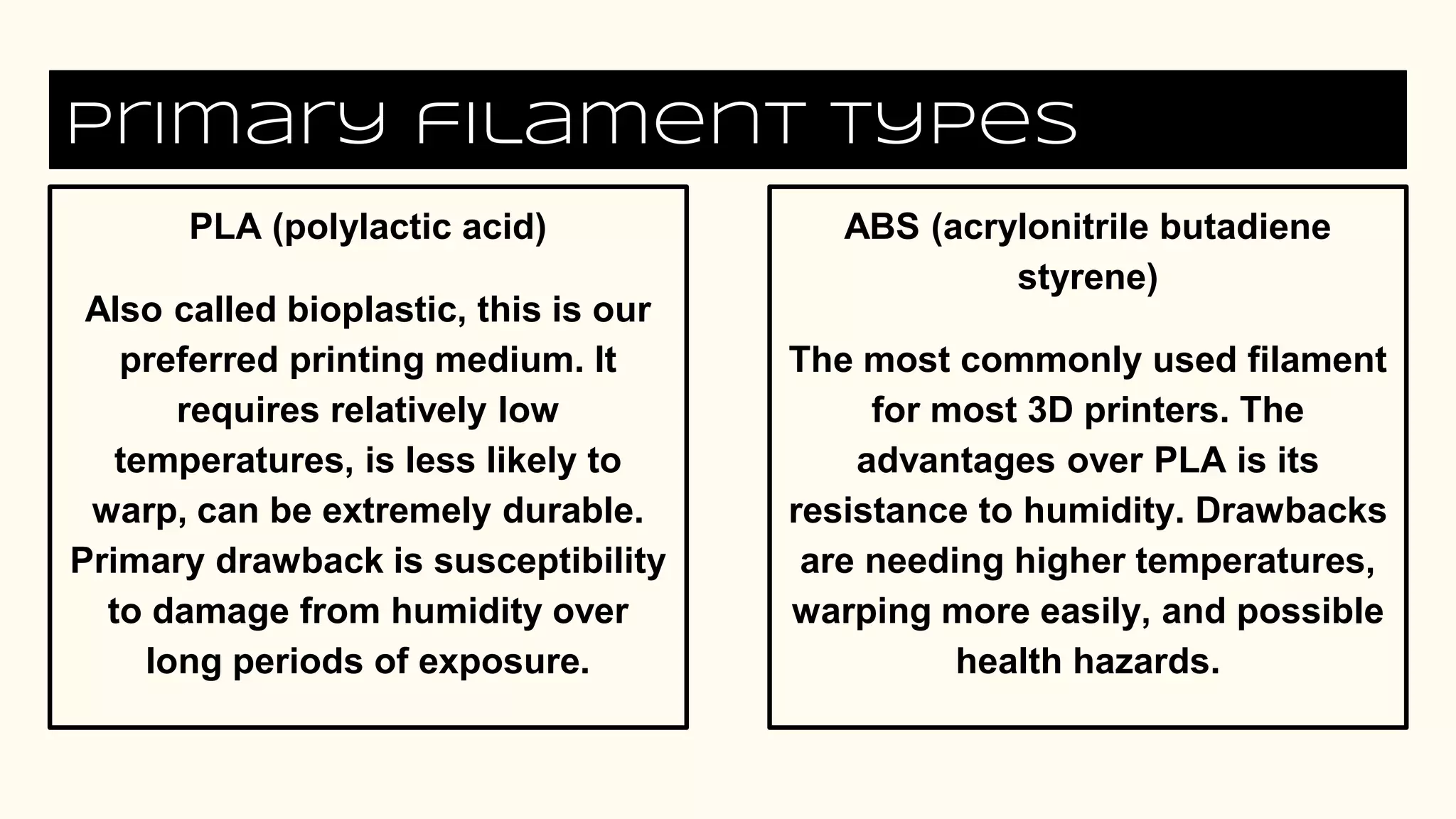

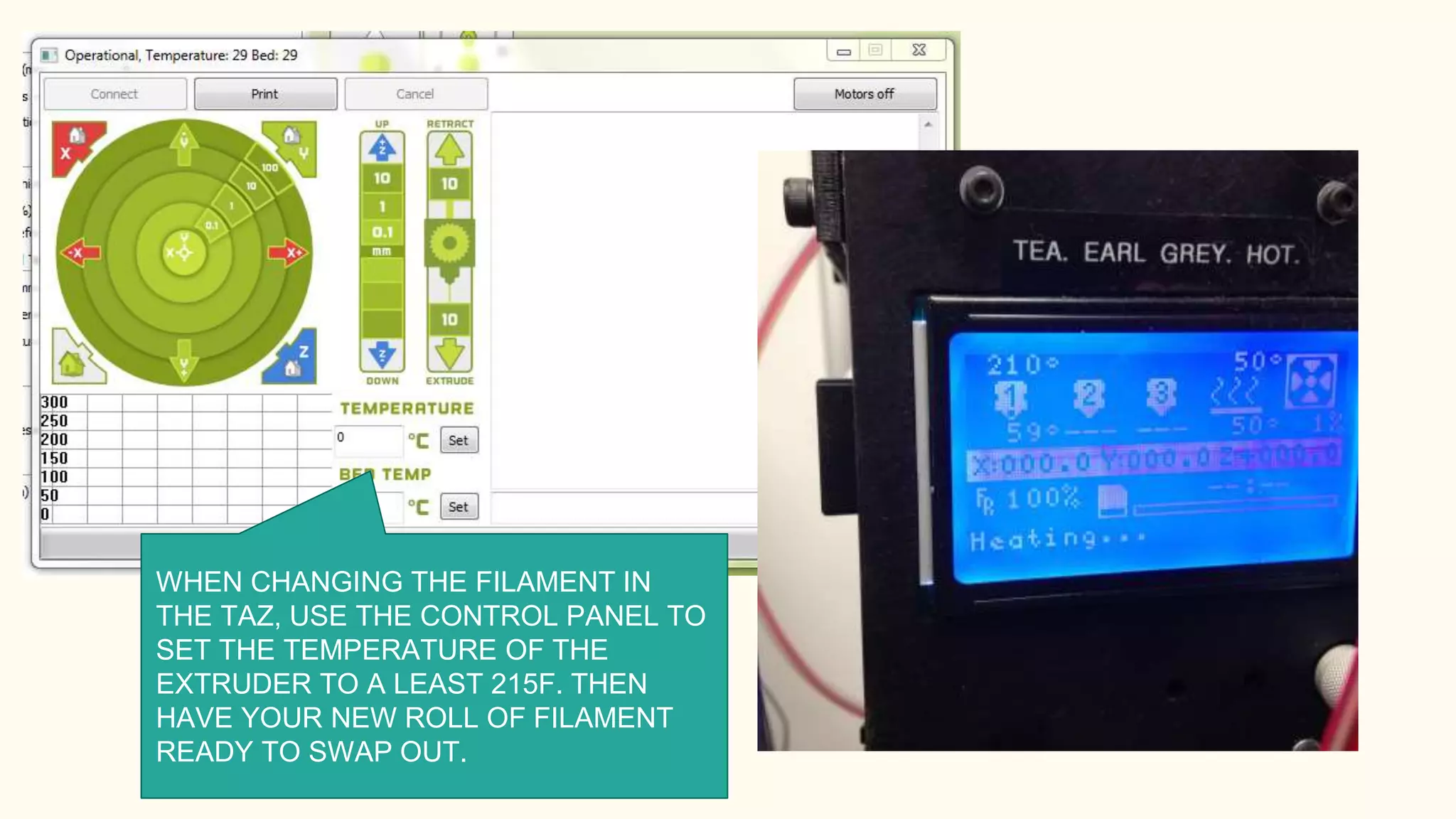

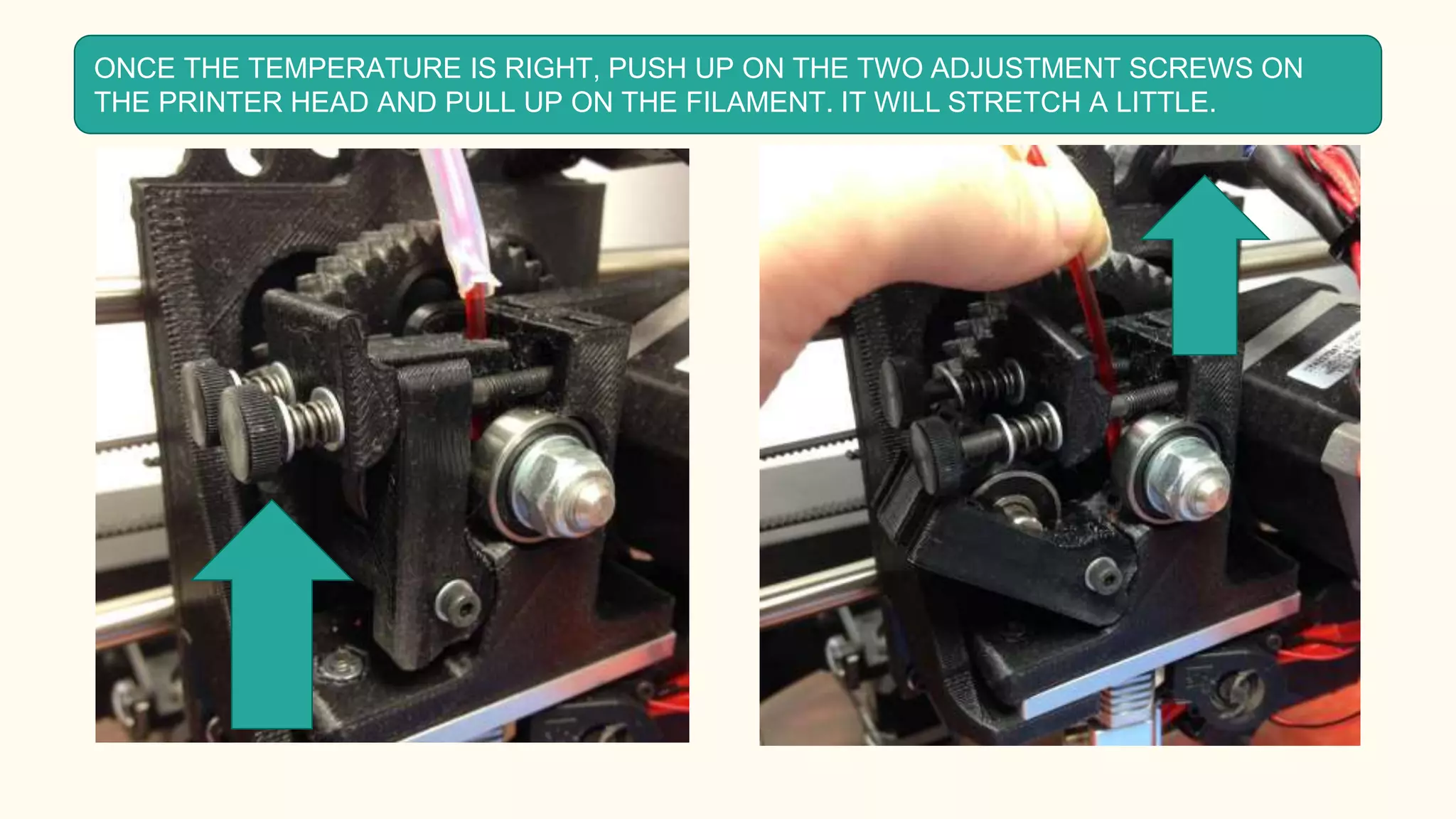

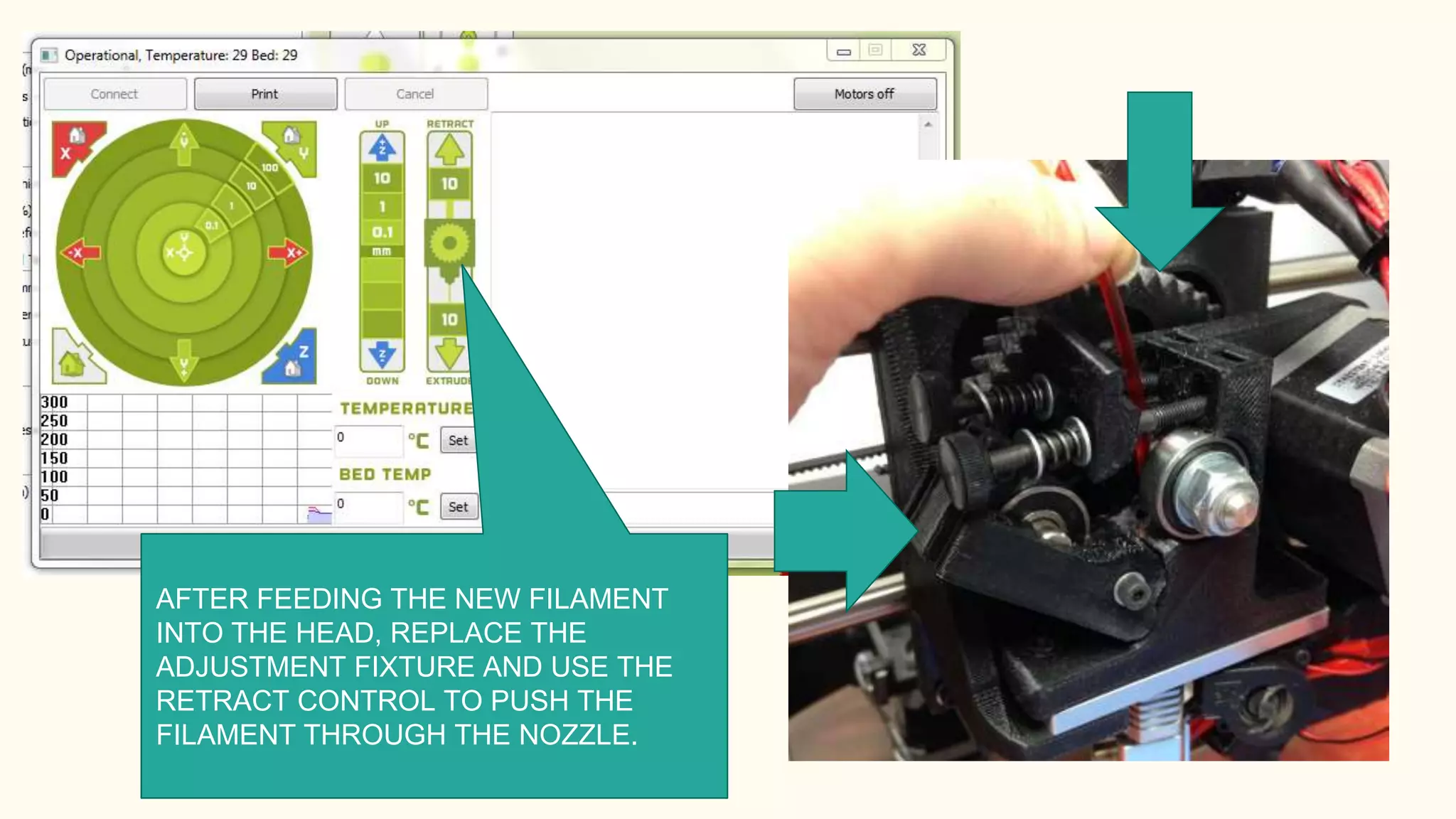

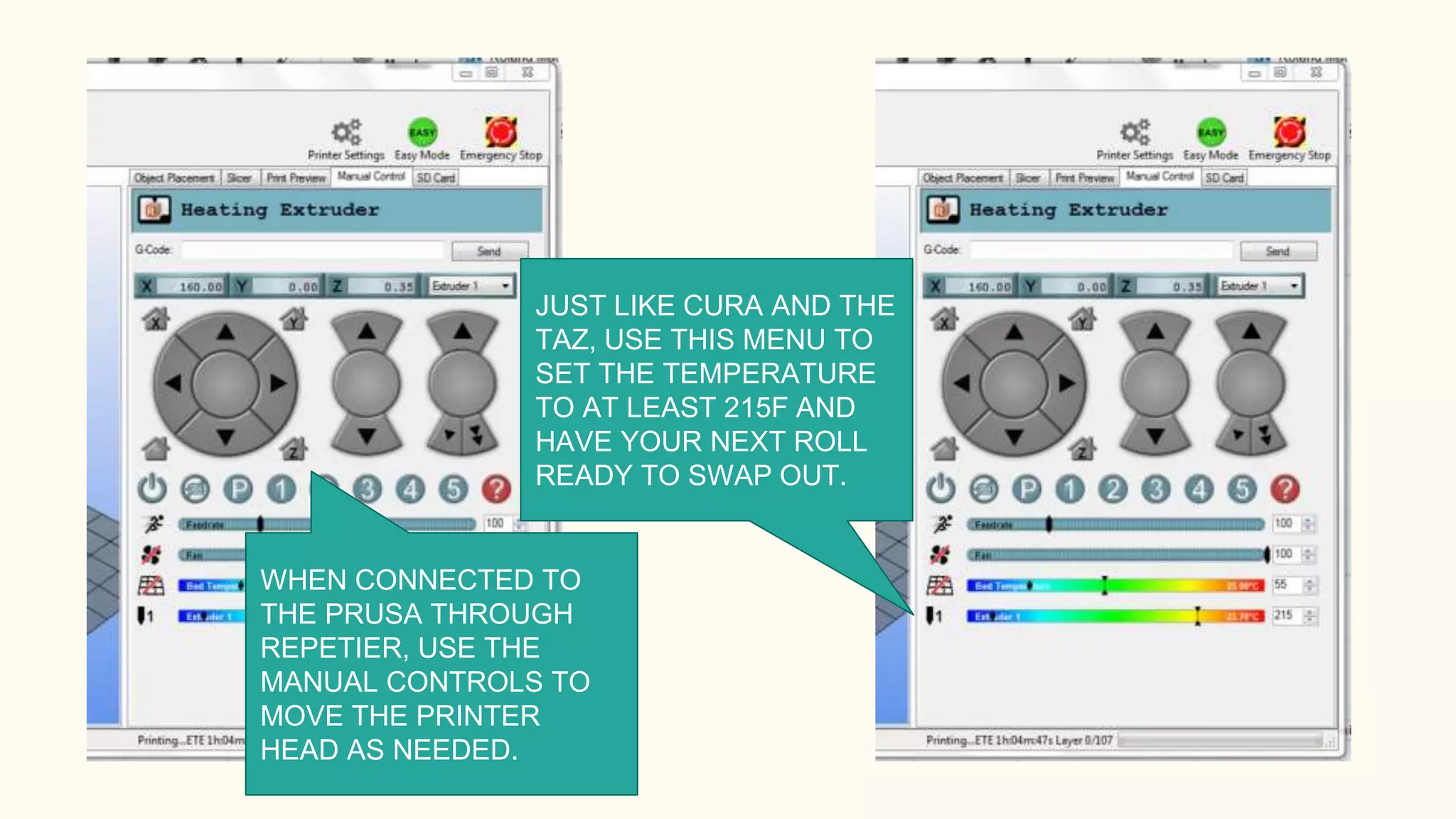

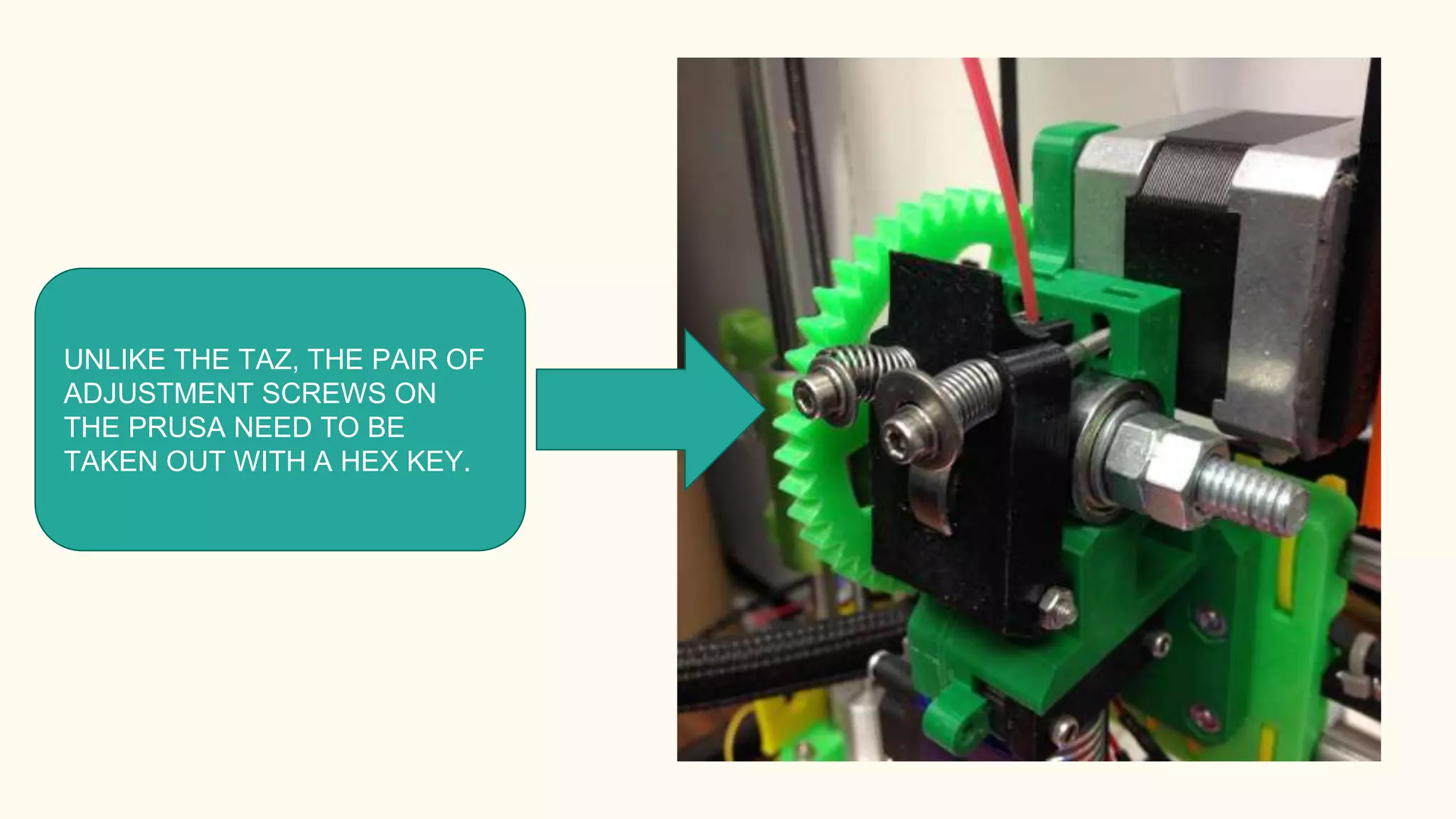

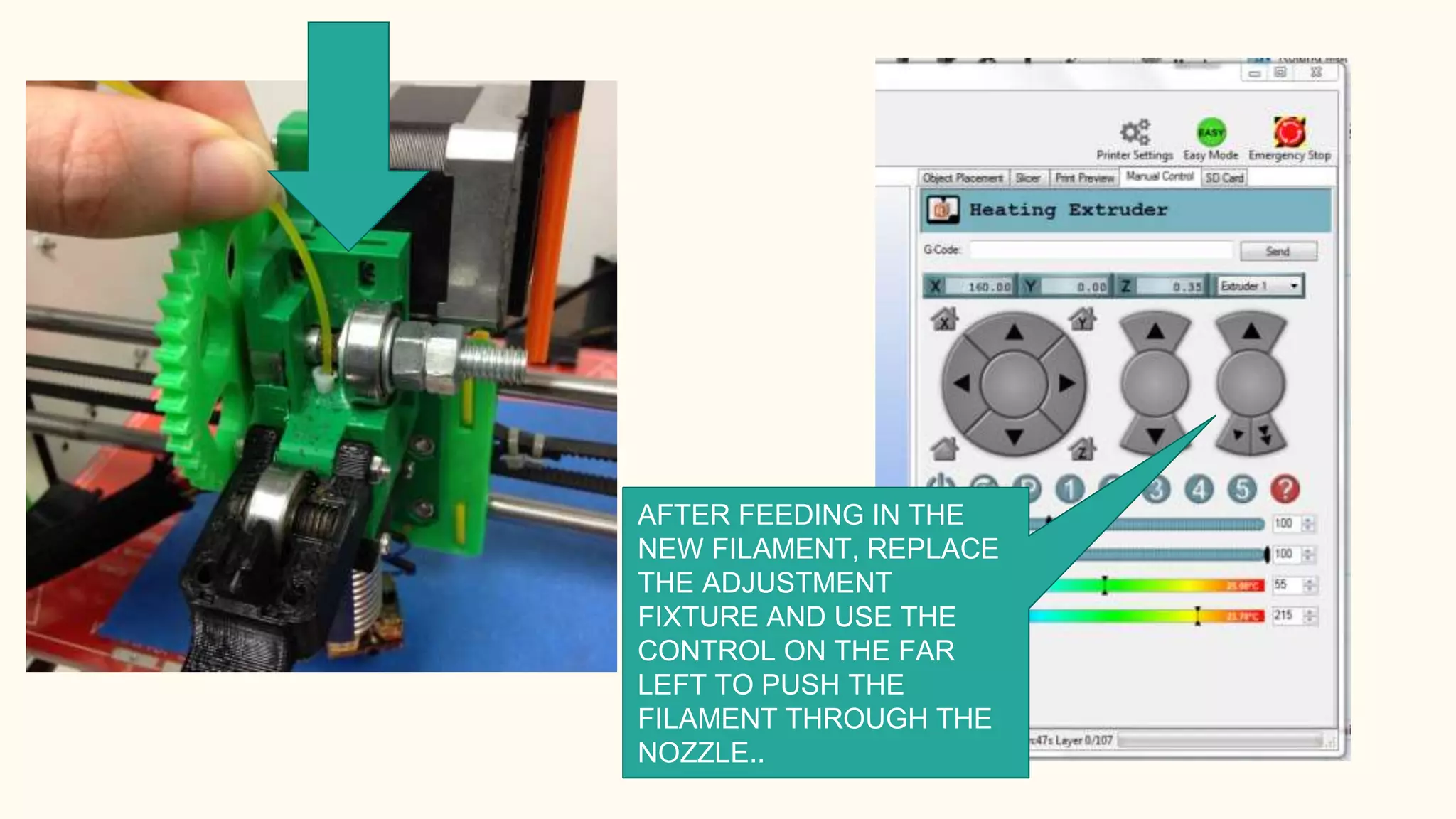

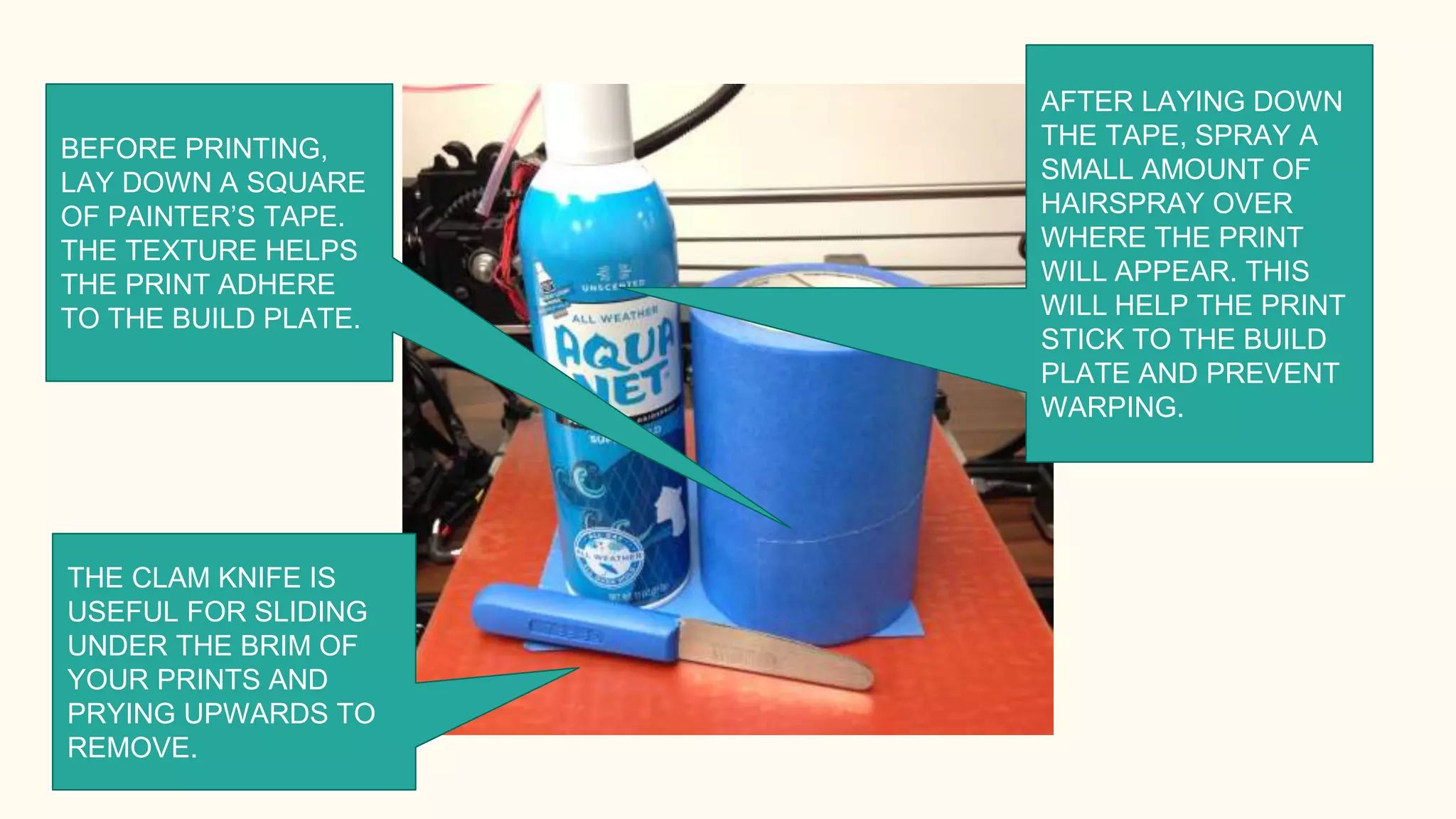

3D printing involves designing a 3D model, converting it to an STL file, slicing the file for 3D printing, and printing the model layer by layer. Key steps include measuring a physical part for modeling, using 3D modeling software to create a digital design, saving the file in the software's format and as an STL, using a slicer program like Cura or Slic3r to prepare the file for printing, and printing with PLA or ABS plastic filament. Changing filament involves heating the extruder, removing the old spool, inserting the new spool, and pushing the filament through the nozzle. Painters tape and hairspray can help parts adhere during printing to prevent war