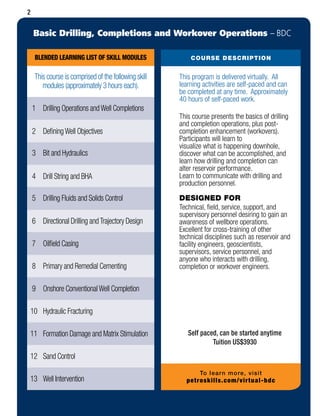

The Petroacademy 2018 Blended Learning Solutions Guide outlines various virtual training courses focused on petroleum technology, drilling operations, geophysics, reservoir engineering, completions, and production operations. Each course offers self-paced and instructor-led activities designed to enhance workforce competency in specific areas of the petroleum industry. The programs are tailored for different skill levels, integrating learning formats such as e-learning, discussion forums, and case studies to facilitate knowledge retention.