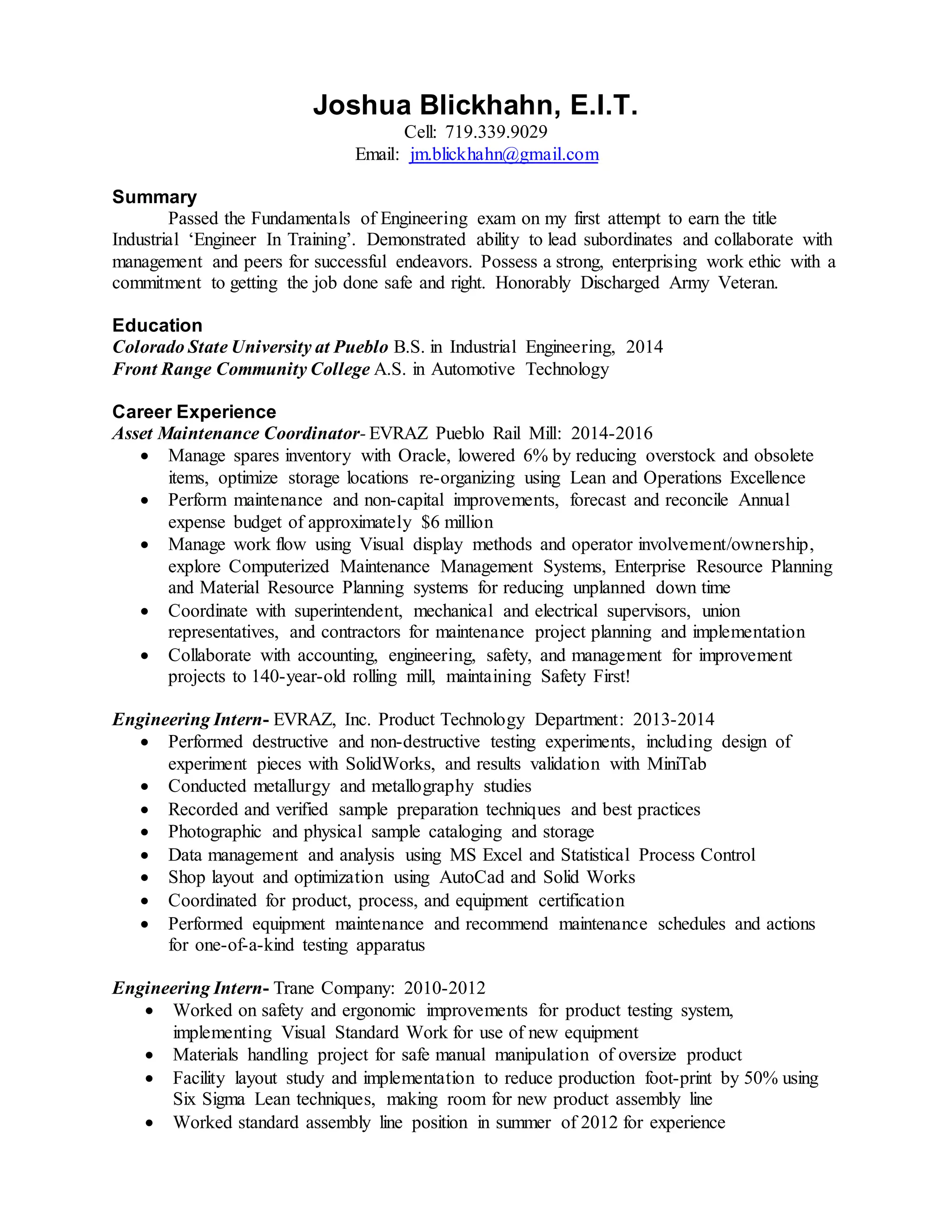

Joshua Blickhahn has experience in engineering, maintenance, and the military. He passed the Fundamentals of Engineering exam and earned an Industrial Engineering degree. He has held roles managing maintenance budgets and coordinating projects. He also has a background in testing, data analysis, and process improvement.