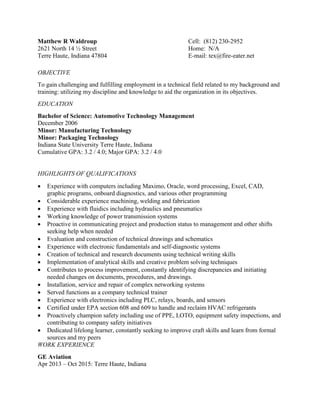

The document provides a resume for Matthew Waldroup. It summarizes his objective as seeking a technical position utilizing his education and experience. It then outlines his education as a Bachelor of Science in Automotive Technology Management from Indiana State University in 2006. The bulk of the resume highlights Matthew's qualifications and work experience in various technical and maintenance roles from 2013 to the present at companies like GE Aviation and Sony DADC, as well as earlier experience from 2000 to 2010 in the military, farming, and various technical roles.